Transfer/Transition slot adjustment

With a combination you've created yourself there will be several iterations of trials as you tune it in.

Lean is more sensitive. So it's easier to turn the screws in small increments until the rpm or vac just begins to drop off. Then turn it back to where the rpm was strongest. I usually give each mix screw a 1/16 to 1/8 turn richer from that so it will be stronger when placed in gear.

Not knowing know what the junkyard 360 came out of, here's some generalizations.

While a 2bbl 318 was pretty efficient at low rpm, the 360s a little so, but the magnum versions and later heads probably a little more efficient.

The less efficient the engine is at idle, the more spark lead it will need.

A slighter hotter cam almost always hurts efficiency at idle - even the factory 4 bbls (pre-smog) have inital timing around 10 to 15* BTC.

However especially with the 4 bbl carb on them, they quickly gain combustion chamber efficiency above 1400 to 1800 rpm.

I'll post some examples of pre-smog factory timing curves below.

Since yours is idling nicely at 6*BTC at 650 rpm that seems like a good starting point.

You could try 4* at 650 rpm but that will probably require opening the throttles a little more to get the rpms back. If it does not require them to be open so much that .035" or more of the t-slots are exposed, it may be worth giving it try.

Likewise you could try 8 or 10* BTC at 650 rpm. If the t-slots are between .020 and .035 that might be worth pursuing. After fiddling with the idle mix put it in gear (if automatic) and see if the rpm and vacuum is stronger than the best tune it had at 6*BTC, 650 rpm.

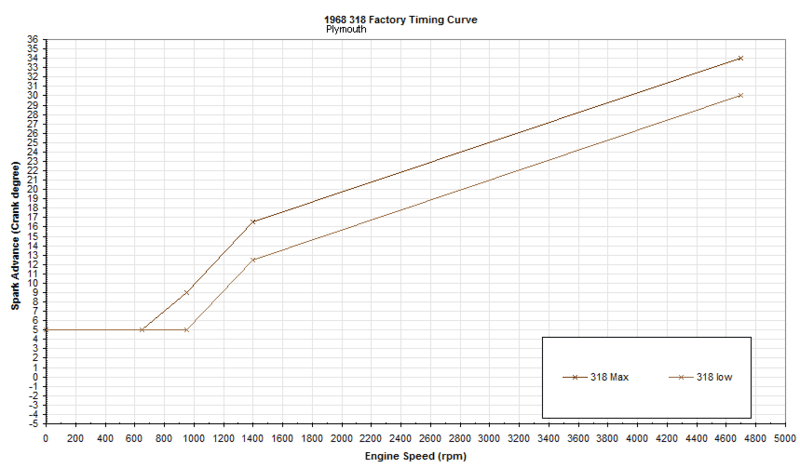

Here's the range of factory timing for a '68 Plymoth 318 2bbl (initial could be set a little higher or lower based on fuel and altitude)

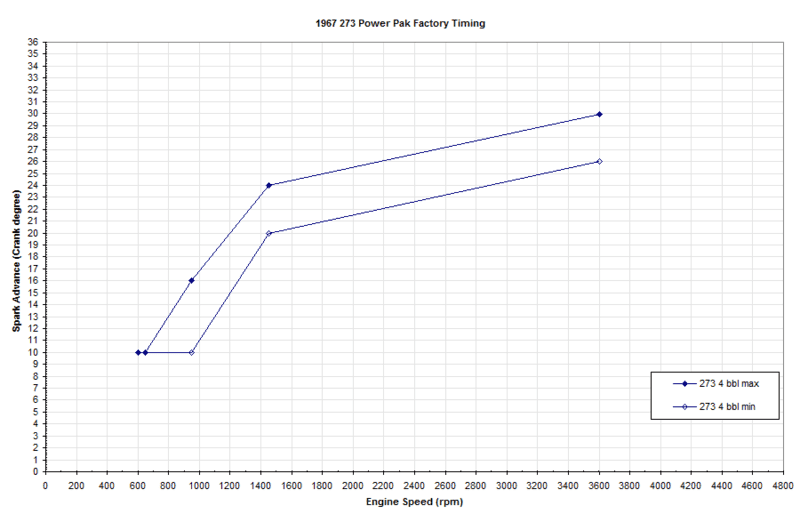

Compared with a '67 273 4 bbl. (initial could be set a little higher or lower based on fuel and altitude)

I chose these examples because they were not Clean Air Package engines.

Notice in both that rate of advance slows above 1400 rpm. That's the heavy spring with long loop engaging.

There's pictures here showing how the springs work on the weights and how they can be adjusted.

If the distrubtor you're using has a mallory YH advance, its done a little differently but concept is same.

Yes. Yes.

With a combination you've created yourself there will be several iterations of trials as you tune it in.

Lean is more sensitive. So it's easier to turn the screws in small increments until the rpm or vac just begins to drop off. Then turn it back to where the rpm was strongest. I usually give each mix screw a 1/16 to 1/8 turn richer from that so it will be stronger when placed in gear.

Not knowing know what the junkyard 360 came out of, here's some generalizations.

While a 2bbl 318 was pretty efficient at low rpm, the 360s a little so, but the magnum versions and later heads probably a little more efficient.

The less efficient the engine is at idle, the more spark lead it will need.

A slighter hotter cam almost always hurts efficiency at idle - even the factory 4 bbls (pre-smog) have inital timing around 10 to 15* BTC.

However especially with the 4 bbl carb on them, they quickly gain combustion chamber efficiency above 1400 to 1800 rpm.

I'll post some examples of pre-smog factory timing curves below.

Since yours is idling nicely at 6*BTC at 650 rpm that seems like a good starting point.

You could try 4* at 650 rpm but that will probably require opening the throttles a little more to get the rpms back. If it does not require them to be open so much that .035" or more of the t-slots are exposed, it may be worth giving it try.

Likewise you could try 8 or 10* BTC at 650 rpm. If the t-slots are between .020 and .035 that might be worth pursuing. After fiddling with the idle mix put it in gear (if automatic) and see if the rpm and vacuum is stronger than the best tune it had at 6*BTC, 650 rpm.

Here's the range of factory timing for a '68 Plymoth 318 2bbl (initial could be set a little higher or lower based on fuel and altitude)

Compared with a '67 273 4 bbl. (initial could be set a little higher or lower based on fuel and altitude)

I chose these examples because they were not Clean Air Package engines.

Notice in both that rate of advance slows above 1400 rpm. That's the heavy spring with long loop engaging.

There's pictures here showing how the springs work on the weights and how they can be adjusted.

If the distrubtor you're using has a mallory YH advance, its done a little differently but concept is same.