Runs then dies

Plymouth shows TDC at 900 for manual trans and TDC to 2.5* BTDC at 750 rpm for automatic.

That works OK only when using the original distributors.

For midlly hot rodded, even with factory cam, with low compression, 12 - 16 BTDC at 700 rpm would be a good starting point.

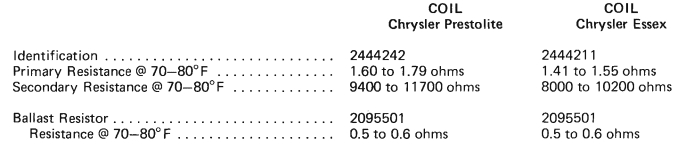

From '72 Plymouth FSM

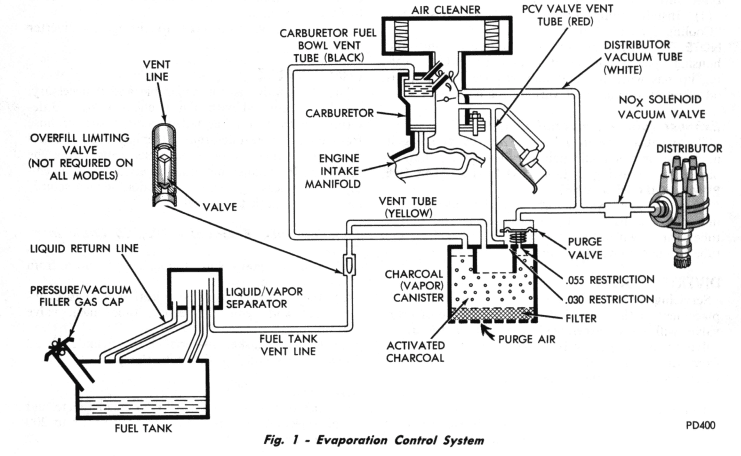

example Vapor canister filter

rebuilding Charcoal Canister?

My previous post pretty much sums up how I'd approach the problem. There's only three things the engine needs to run; fuel air mix, spark, compression. Divide and conquer.

Good luck.

Well that's way off, although I don't think its related to the issue.

Plymouth shows TDC at 900 for manual trans and TDC to 2.5* BTDC at 750 rpm for automatic.

That works OK only when using the original distributors.

For midlly hot rodded, even with factory cam, with low compression, 12 - 16 BTDC at 700 rpm would be a good starting point.

If accurate that's a problem. Should show a over an ohm. Not all multimeters will be sensitive enough but 0 is a short.

From '72 Plymouth FSM

That means nothing. Even if they did a wondeerful job, that was 2900 miles ago. Shavings, dirt, varnish, or charcoal all could have developed or moved around until they block a passage.

Not a great test and a good way to get hurt. I'd go with that conclusion for now but keep in mind it could be wrong. The checks I listed above are relatively safe and will get closer to the source of the problem.

I wouldn't count on that. The canister has filters from when? 1972? and then depending on how the system is set up, when the charcoal has broken down it can make its way to the carb. Worst is if the bowls have vent direct to the cannister. If its open when the engine is running, charcoal dust migrates. Service manual doesn't show a shutoff when the engine is running... I wouldnt write off that possibility.

example Vapor canister filter

rebuilding Charcoal Canister?

My previous post pretty much sums up how I'd approach the problem. There's only three things the engine needs to run; fuel air mix, spark, compression. Divide and conquer.

Good luck.