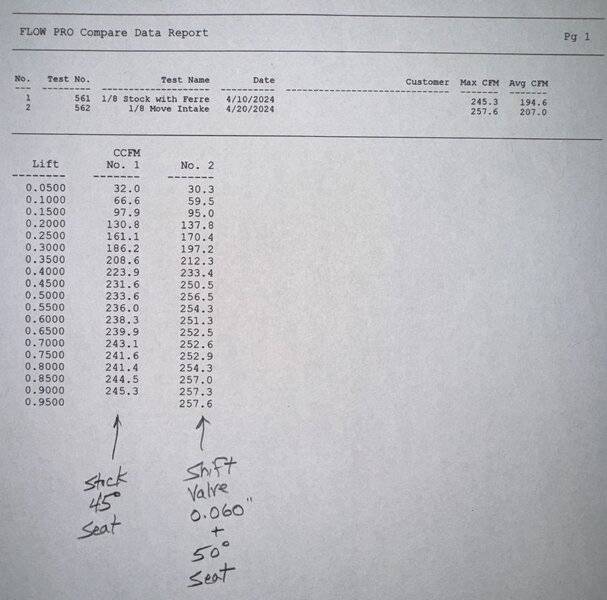

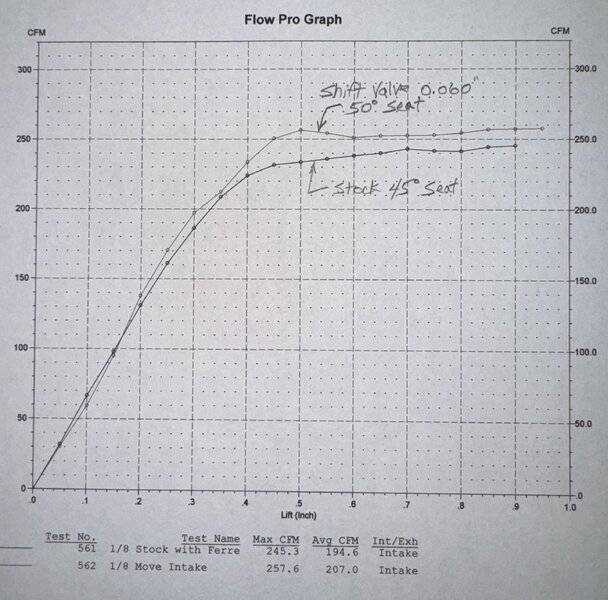

Here's before and after data from the same port on a stock Speedmaster SBM head, not CNC'd.

Before: OOTB stock 15/45/60/90 valve job with Ferrea 30/45 valve, 90.2% throat. No modifications to port or chamber.

After: Intake valve shifted 0.060", exhaust valve shifted 0.080". Valves sunk 0.085" to achieve 40/50/65/75/80 valve job with Ferrea 35/50 valve, 89.6% throat. Top cuts extended to 4.07" bore width. Light blending of new valve job to port and chamber. No modifications to port other than blending to new valve job.

This comparison would be more meaningful if the second valve job was identical to the first, but I was not about to go through the work of moving the valves and then ruin the work with a 15 degree top cut. Much of the flow gains seen here can be contributed to the new valve job and the wide/steep top cut, but I do believe some of the gains starting at 0.200 lift and up are due to deshrouding of the valve on the cylinder wall side. Moving the valve also creates additional port 'bias' that the stock port does not have because of the head bolt location. That should help top end flow a little.

Ultimately, the port will be enlarged (ported) and compared to a ported port with stock valve locations. Here are some of the things I'm trying to achieve and learn:

1. Gain width at the apex of the short side. Moving the valve 0.060" should allow for nearly that much additional width at the apex, if the air flow will stay attached to the pushrod wall. This should help lower velocity over the short turn and keep flow attached to the short turn (for a little longer) at higher lifts.

2. Gain port bias. Vizard is a big proponent of leaning the port to the common wall side. Moving the valve should allow for a little more bowl width and bias.

3. Deshroud the valve on the cylinder wall side.

4. Increase pushrod pinch width. If the valve is moved 0.060", the pushrod pinch could be widened by 0.030-0.040".

I realize that this is somewhat of an impractical test. Moving valves, moving spring seats and rocker arms can be a complicated and expensive endeavor. As with many of the tests that I have been running, it's all about learning something.

Before: OOTB stock 15/45/60/90 valve job with Ferrea 30/45 valve, 90.2% throat. No modifications to port or chamber.

After: Intake valve shifted 0.060", exhaust valve shifted 0.080". Valves sunk 0.085" to achieve 40/50/65/75/80 valve job with Ferrea 35/50 valve, 89.6% throat. Top cuts extended to 4.07" bore width. Light blending of new valve job to port and chamber. No modifications to port other than blending to new valve job.

This comparison would be more meaningful if the second valve job was identical to the first, but I was not about to go through the work of moving the valves and then ruin the work with a 15 degree top cut. Much of the flow gains seen here can be contributed to the new valve job and the wide/steep top cut, but I do believe some of the gains starting at 0.200 lift and up are due to deshrouding of the valve on the cylinder wall side. Moving the valve also creates additional port 'bias' that the stock port does not have because of the head bolt location. That should help top end flow a little.

Ultimately, the port will be enlarged (ported) and compared to a ported port with stock valve locations. Here are some of the things I'm trying to achieve and learn:

1. Gain width at the apex of the short side. Moving the valve 0.060" should allow for nearly that much additional width at the apex, if the air flow will stay attached to the pushrod wall. This should help lower velocity over the short turn and keep flow attached to the short turn (for a little longer) at higher lifts.

2. Gain port bias. Vizard is a big proponent of leaning the port to the common wall side. Moving the valve should allow for a little more bowl width and bias.

3. Deshroud the valve on the cylinder wall side.

4. Increase pushrod pinch width. If the valve is moved 0.060", the pushrod pinch could be widened by 0.030-0.040".

I realize that this is somewhat of an impractical test. Moving valves, moving spring seats and rocker arms can be a complicated and expensive endeavor. As with many of the tests that I have been running, it's all about learning something.

Last edited: