396 Signet

Well-Known Member

Recently finished a 9.5 to 10.5 inch clutch conversion on my car (65 Valiant). I originally tried to use a special 9.5-in setup with a so-called street iron disc that ultimately didnt work out for a couple of reasons. I have a mildly built stroked 340 (396ci) with a very light rotating assembly. With the light flywheel & clutch it was just too responsive which sounds good but is not for practical driving. Second the iron disc with marcel springs was initially smooth but with miles degraded to basically an on-off switch. It cost me roughly $1k for the change but you could go more or less depending on what parts and deals you find.

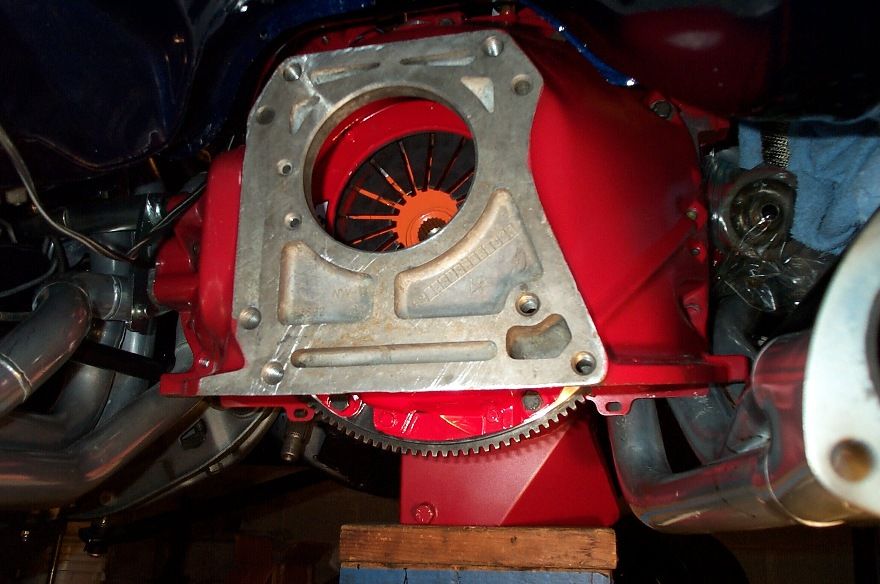

Some of the 10.5 clutch kits are unbelievably cheap, like under $100 for a complete setup that includes throwout bearing & install tool. I was uncomfortable with the quality of those so bit the bullet & bought some higher quality stuff. Bought the McLeod SFI 130-tooth flywheel (464102), McLeod diaphragm pressure plate (360703), & Hays organic disc (55-104) from Summit. The McLeod PP is has the standard pressure rating of 2750 lbs which is perfect for my limited traction but they make another with about 500lbs more if you need it. Ive come to prefer the diaphragm types over the original Borg & Beck for various reasons. You do have to remove the pedal overcenter spring for the diaphragm types.

The complete clutch linkage conversion is available from Brewers. Basically you will need a new ball stud mounting bracket, a shorter Z-bar, a longer push-rod with a slight bend, and a slightly longer clutch fork although you might be able to use the original fork. You could save a few bucks & fabricate some of this stuff yourself but its really just not worth it since theyve done all the engineering & it works well.

I used an original 68-71 aluminum bellhousing 2892482. Others may work but cant comment.

The install was very straightforward with a few minor issues. I removed the steering linkage so that the engine could be dropped a bit more for better bolt access although this might not be necessary. I had to do this anyway because one of the linkage castle nuts was rubbing on a header pipe & had to be grinded a bit. The Dougs headers are a really tight fit but I did everything with them installed. All the 10.5 bellhousing bolts can be installed from below using various tricks like swivel sockets except for the top center bolt which due to the bowed-out bellhousing shape can only be accessed with a box wrench from the top. I did NOT have to hammer down the firewall pinch weld like some say- there was plenty of room. There was a clearance issue with the clutch inspection cover & dust shield with one of the pipes on the right side so had to remove a little material from both. The run-of-the-mill mini-starter I used with the 9.5 would barely fit the 10.5 (just touching pipes) so I looked around for something different (the original battle ship starter is an absolute no-go). Ended up going with the McRobb unit which is pricey but has huge clearance, its recommended by TTI. The clutch fork pivot originally used with the 10.5 bell would not work with the Dougs headers as it angles the fork so that it hits the pipes. You will need to transfer the 9.5 pivot to the 10.5 bellhousing. Lastly due to the very tight clearances I loosened or removed the engine/ trans mount bolts, jacked it up & positioned for best clearance- theres a surprising amount of leeway there.

Took lots of pics if anyone needs.

Some of the 10.5 clutch kits are unbelievably cheap, like under $100 for a complete setup that includes throwout bearing & install tool. I was uncomfortable with the quality of those so bit the bullet & bought some higher quality stuff. Bought the McLeod SFI 130-tooth flywheel (464102), McLeod diaphragm pressure plate (360703), & Hays organic disc (55-104) from Summit. The McLeod PP is has the standard pressure rating of 2750 lbs which is perfect for my limited traction but they make another with about 500lbs more if you need it. Ive come to prefer the diaphragm types over the original Borg & Beck for various reasons. You do have to remove the pedal overcenter spring for the diaphragm types.

The complete clutch linkage conversion is available from Brewers. Basically you will need a new ball stud mounting bracket, a shorter Z-bar, a longer push-rod with a slight bend, and a slightly longer clutch fork although you might be able to use the original fork. You could save a few bucks & fabricate some of this stuff yourself but its really just not worth it since theyve done all the engineering & it works well.

I used an original 68-71 aluminum bellhousing 2892482. Others may work but cant comment.

The install was very straightforward with a few minor issues. I removed the steering linkage so that the engine could be dropped a bit more for better bolt access although this might not be necessary. I had to do this anyway because one of the linkage castle nuts was rubbing on a header pipe & had to be grinded a bit. The Dougs headers are a really tight fit but I did everything with them installed. All the 10.5 bellhousing bolts can be installed from below using various tricks like swivel sockets except for the top center bolt which due to the bowed-out bellhousing shape can only be accessed with a box wrench from the top. I did NOT have to hammer down the firewall pinch weld like some say- there was plenty of room. There was a clearance issue with the clutch inspection cover & dust shield with one of the pipes on the right side so had to remove a little material from both. The run-of-the-mill mini-starter I used with the 9.5 would barely fit the 10.5 (just touching pipes) so I looked around for something different (the original battle ship starter is an absolute no-go). Ended up going with the McRobb unit which is pricey but has huge clearance, its recommended by TTI. The clutch fork pivot originally used with the 10.5 bell would not work with the Dougs headers as it angles the fork so that it hits the pipes. You will need to transfer the 9.5 pivot to the 10.5 bellhousing. Lastly due to the very tight clearances I loosened or removed the engine/ trans mount bolts, jacked it up & positioned for best clearance- theres a surprising amount of leeway there.

Took lots of pics if anyone needs.