70DusterDev

Well-Known Member

Maybe the A1000 for me?

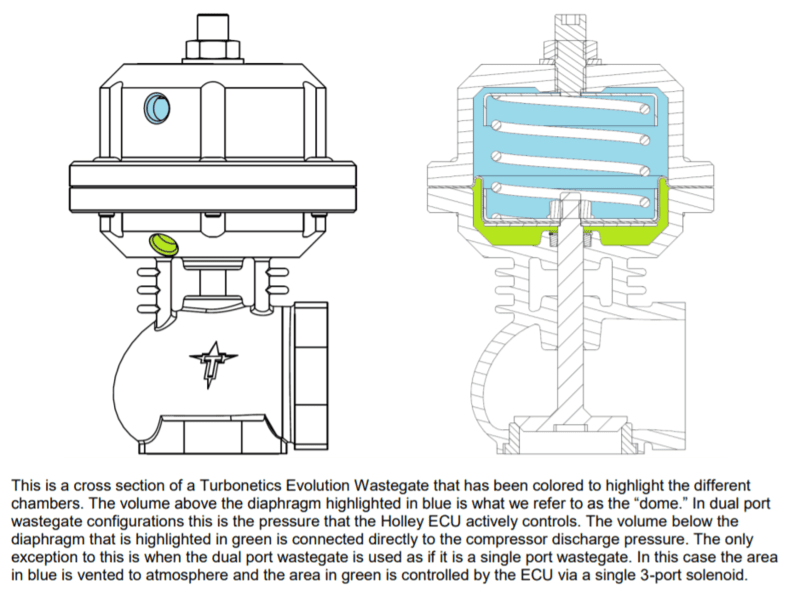

Also since you've done this a bit maybe you can help me understand this. I'm running a single solenoid holley electronic boost controller on the 44mm wastegate. So my line from the solenoid goes to the bottom half of the wastegate with the top half open to atmosphere I read from the holley page. If so then that pressure will help push the diaphragm up making the spring seem even weaker no? Because the exhaust pressure is also pushing up on the valve/spring. You'd think you'd want your boost to be on the top side of the dome helping the spring keep the valve closed and as you adjust pressure it allows it to open?

Also since you've done this a bit maybe you can help me understand this. I'm running a single solenoid holley electronic boost controller on the 44mm wastegate. So my line from the solenoid goes to the bottom half of the wastegate with the top half open to atmosphere I read from the holley page. If so then that pressure will help push the diaphragm up making the spring seem even weaker no? Because the exhaust pressure is also pushing up on the valve/spring. You'd think you'd want your boost to be on the top side of the dome helping the spring keep the valve closed and as you adjust pressure it allows it to open?

Last edited: