tanis4457

Well-Known Member

Figured I'd share my engine build that I'm working on. First time building a motor and wanted to get a little more performance out of it. When I first tore the motor down the pistons were in the hole about 0.100" and it had already been bored 0.030" over in the past. The J heads on the engine already had 2.02 intake valves installed in the past. All my machine work was done at Tom's Performance Machine and Repair | Auto Repair, Performance Tuning and Machine Fabrication located in Vancouver, WA | Quality Brands Used including Elderbrock, Felpro, NGK and more | Proudly serving our neighbors in Portland and Battle Ground.

Here's the basic break down of the motor.

71 360 block bored 0.040" over stock stroke.

J heads cleaned with new valves 2.02 intake/ 1.6 exhaust installed, hardened seats installed, minor bowl blending. Recommendation was to not put too much into the heads.

ICON forged pistons with OEM rods, ARP bolts in the rods.

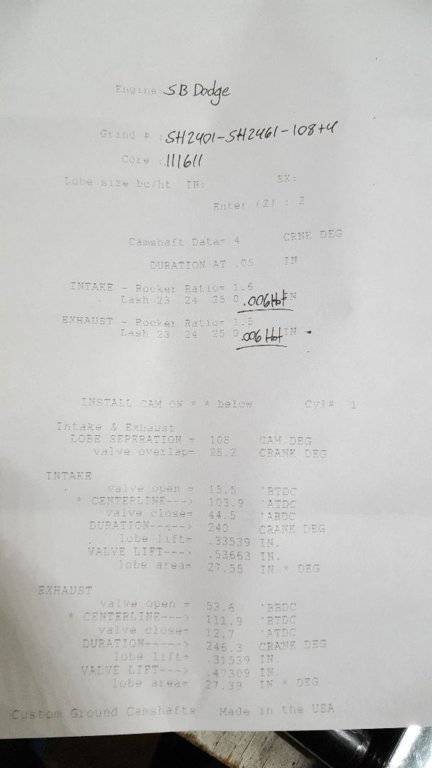

Custom cam, I've included a pic of the cam card.

HV oil pump.

Kevko oil pan.

B3 racing engines roller rocker assembly 1.6 intake/1.5 exhaust.

Edelbrock single plane intake with a Holley Sniper EFI setup that I was already running on this motor in it's previous configuration.

Basically everything else is pretty much standard. I'll try and upload pics and info along the way.

Here's the basic break down of the motor.

71 360 block bored 0.040" over stock stroke.

J heads cleaned with new valves 2.02 intake/ 1.6 exhaust installed, hardened seats installed, minor bowl blending. Recommendation was to not put too much into the heads.

ICON forged pistons with OEM rods, ARP bolts in the rods.

Custom cam, I've included a pic of the cam card.

HV oil pump.

Kevko oil pan.

B3 racing engines roller rocker assembly 1.6 intake/1.5 exhaust.

Edelbrock single plane intake with a Holley Sniper EFI setup that I was already running on this motor in it's previous configuration.

Basically everything else is pretty much standard. I'll try and upload pics and info along the way.