brian 1972

Member

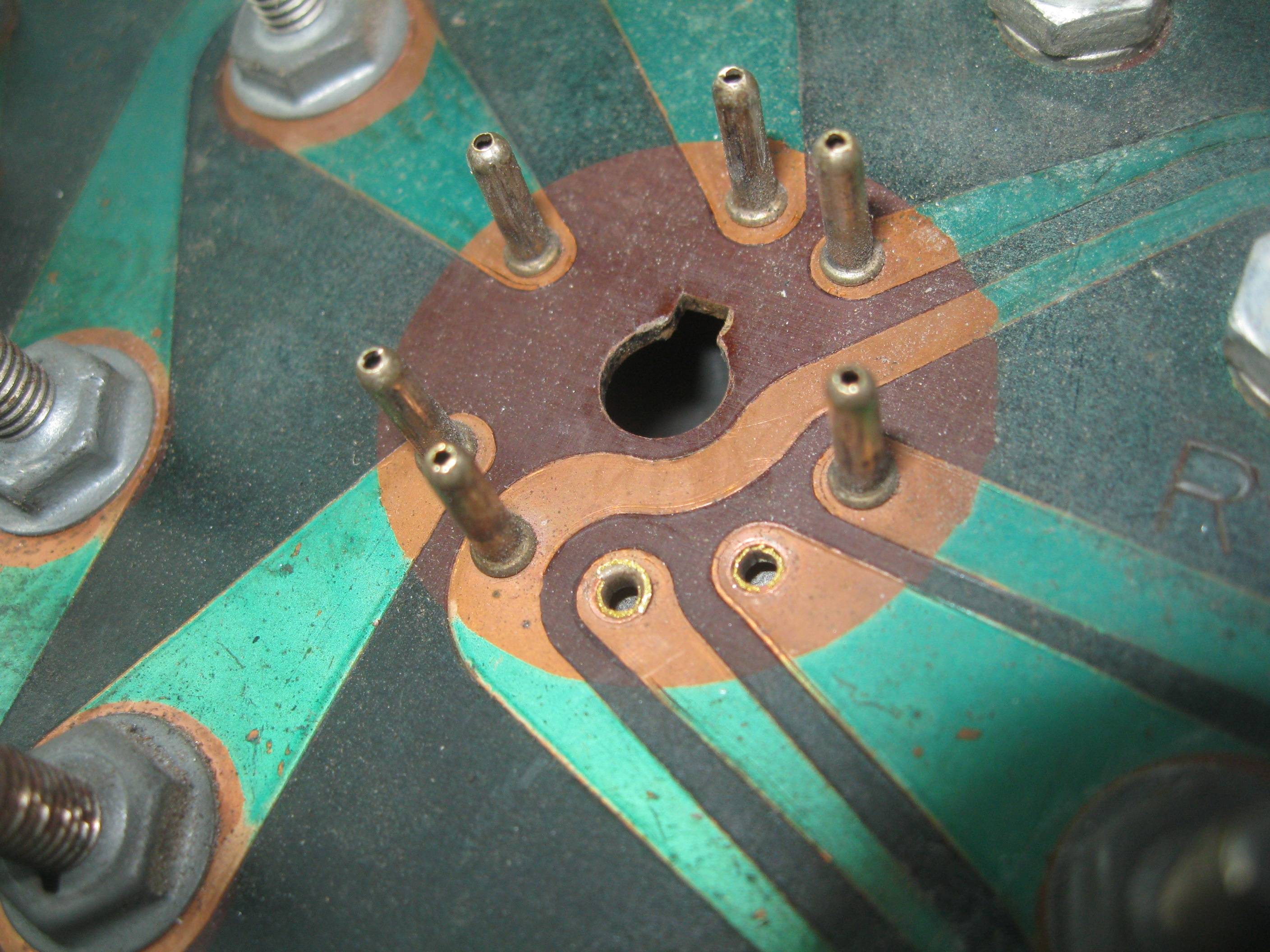

i removed the dash from my 68 barracuda and 2 of the prongs on the back of the circuit board was broke off gone wondering if theres a way to fix it

Check the socket for those two pins and solder them back on.

Lots of people have done it.