You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

68 GT convertible project

- Thread starter burdar

- Start date

-

Here are some more parts I've been working on. Now that the parts came back from the plater, I've been able to put a few things back together.

parking light housings before

After a long EvapoRust soak. I hit the sockets with the buffing wheel to get them looking a little nicer...not perfect but I hope they won't be too noticeable behind the grill.

Shifter before...

after...

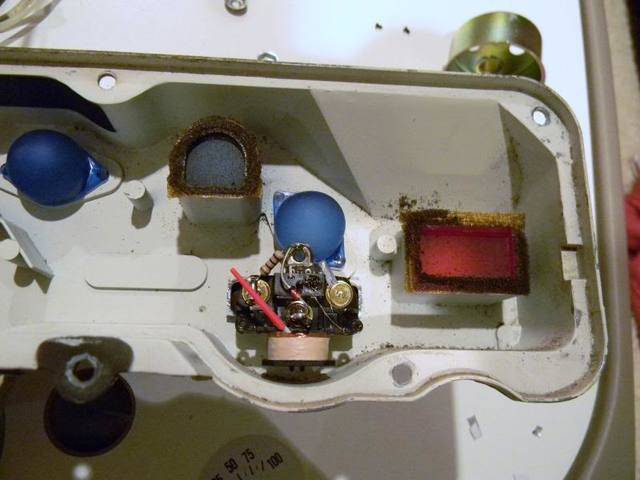

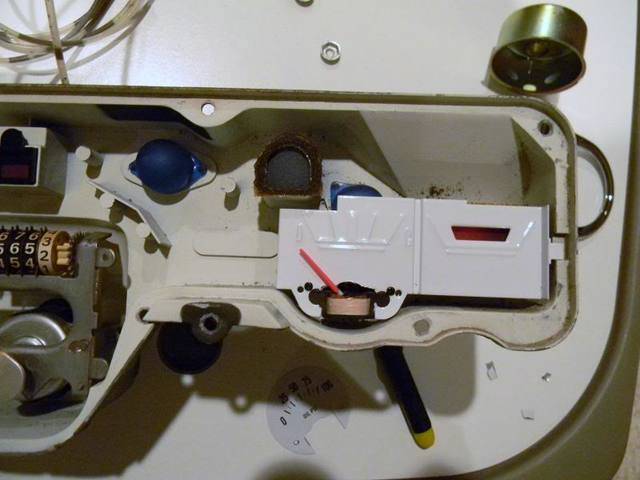

E-brake mechanism before...

I still need to buy a different handle. Mine is broken.

DS fresh air door before...

Even after spraying the door with high build primer and sanding it out, it looked really bad. I ended up spraying it with wrinkle paint. I like the look and will be doing the same thing to the heater box door. The hinge was in bad shape so I added another rivet in the center for some more support.

I just cleaned up the rear end bumpers. The brackets are coated with RPM so they won't rust.

parking light housings before

After a long EvapoRust soak. I hit the sockets with the buffing wheel to get them looking a little nicer...not perfect but I hope they won't be too noticeable behind the grill.

Shifter before...

after...

E-brake mechanism before...

I still need to buy a different handle. Mine is broken.

DS fresh air door before...

Even after spraying the door with high build primer and sanding it out, it looked really bad. I ended up spraying it with wrinkle paint. I like the look and will be doing the same thing to the heater box door. The hinge was in bad shape so I added another rivet in the center for some more support.

I just cleaned up the rear end bumpers. The brackets are coated with RPM so they won't rust.

Last edited:

I read where guys who restore old bikes use Wood Bleach to clean certain things. I was curious how it would work on aluminum so I bought some to try. I used 1 table spoon of the powder in 1/2 gallon of boiling water. I had some old coil spring spacers sitting around so I put one in the bleach. This is after a three hour soak and a few scrubs with a tooth brush.

I decided to see how the wiper pivots would clean up today. I disassembled them a few days ago. I'll post a picture of the entire assembly once I have everything back together.

after soak in wood bleach

I decided to see how the wiper pivots would clean up today. I disassembled them a few days ago. I'll post a picture of the entire assembly once I have everything back together.

after soak in wood bleach

Last edited:

Here's the 360 that will be going in the Dart. As you can see, its been sitting for awhile. It's a MP shortblock bored .020 with 10 to 1 compression. Ported 360 heads with 1.88in 1.60ex valves and a 484 purpleshaft cam. The trans is a 904 with a 10" 3500 stall convertor and a TF-2 TransGo shift kit.

Before tearing it down for inspection and gasket replacement, I'm going to test fit the parts I bought for it. I'm also going to get the kickdown linkage working and modified before everything is taken apart. I had a thermoquad on this engine before but I'm not sure what to run now. I want something that won't starve the engine but at the same time, I don't want to get horrible mileage either.

Before tearing it down for inspection and gasket replacement, I'm going to test fit the parts I bought for it. I'm also going to get the kickdown linkage working and modified before everything is taken apart. I had a thermoquad on this engine before but I'm not sure what to run now. I want something that won't starve the engine but at the same time, I don't want to get horrible mileage either.

Last edited:

The shifter pivot bracket on the trans cleaned up really nice. I still need to get a new bushing. The original one was in two pieces.

after

I just got done rebuilding one of the horns. Only one of them worked when I tested it. I'll probably just blast and repaint the working horn. I read a post, that Mike from BE&A wrote, on how to rebuild Prestolite horns. I thought I'd try it out on this Sparton horn.

First I drilled the heads off of all six rivets and separated the two halves.

With the horn separated, I drilled out the rivets and tapped them for some 8-32 screws. To clean the contacts, I doubled up some sand paper and inserted it in between the contacts. Then I just pulled out the sand paper. I did this a few times to make sure the contacts were good and clean. The spring steel center piece just had some minor surface rust on it so I just left it alone. If you blast the center piece you will ruin it.

I found an old Christmas box that my wife had been saving and used it to make two new gaskets. There is one gasket on either side of the center piece. I used four C-clamps to hold the horn together in order to test it. All that it took to get it working again was to sand the contacts.

Once the horn was screwed back together, all it needs is a coat of paint. If I were doing a stock restoration I would have used longers screws...cut the ends off flush with the stock rivets and ground down the head of the screw to look more stock.

after

I just got done rebuilding one of the horns. Only one of them worked when I tested it. I'll probably just blast and repaint the working horn. I read a post, that Mike from BE&A wrote, on how to rebuild Prestolite horns. I thought I'd try it out on this Sparton horn.

First I drilled the heads off of all six rivets and separated the two halves.

With the horn separated, I drilled out the rivets and tapped them for some 8-32 screws. To clean the contacts, I doubled up some sand paper and inserted it in between the contacts. Then I just pulled out the sand paper. I did this a few times to make sure the contacts were good and clean. The spring steel center piece just had some minor surface rust on it so I just left it alone. If you blast the center piece you will ruin it.

I found an old Christmas box that my wife had been saving and used it to make two new gaskets. There is one gasket on either side of the center piece. I used four C-clamps to hold the horn together in order to test it. All that it took to get it working again was to sand the contacts.

Once the horn was screwed back together, all it needs is a coat of paint. If I were doing a stock restoration I would have used longers screws...cut the ends off flush with the stock rivets and ground down the head of the screw to look more stock.

Last edited:

2fine69s

69 340-6pak Rag Top

Great Work.....Keep it up, I'm hooked on this post!!!!

AlV

Crabs in a barrel

Nice work!... and you're style is very familiar I like it very much  . Did you use "Vaporust" on all of those pieces including the shifter? the results are great!

. Did you use "Vaporust" on all of those pieces including the shifter? the results are great!

-AlV

-AlV

On delicate parts I use EvapoRust. Most of the parts I use muriatic acid. It works a lot faster and never loses strength. EvapoRust loses strength very fast. You have to be careful with muriatic acid. Use it outside and make sure to neutralize it with baking soda. If you don't, it will continue to eat away at the part.

AlV

Crabs in a barrel

Thanks!On delicate parts I use EvapoRust. Most of the parts I use muriatic acid. It works a lot faster and never loses strength. EvapoRust loses strength very fast. You have to be careful with muriatic acid. Use it outside and make sure to neutralize it with baking soda. If you don't, it will continue to eat away at the part.

I'll do some experimenting on scraps. before I do my parts.

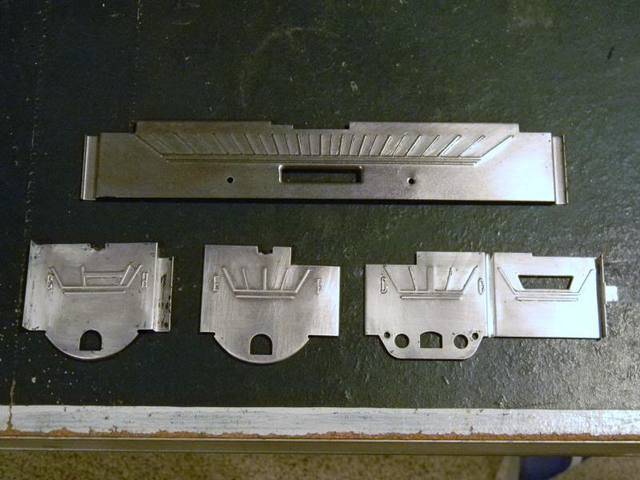

Some more progress on the dash assembly.

I've been working on the gauge cluster. I'm pretty much done with what I can do myself. I still need to have the fuel, temp gauges as well as the speedo checked for calibration and buy a solid state voltage limiter.

Since the car didn't come with an oil pressure gauge, I wanted to install one. However, I didn't want any gauges mounted in pods up under the dash either.(I don't really like that look) I also wanted to keep the idiot light. There wasn't room in the housing for a gauge and the light in the same place. I was planning on doing away with the AMP gauge anyway so I decided to install an oil pressure gauge in its place. If I think I really need to monitor the charging system, I can install a volt meter in the console ashtray. That way it can be hidden.

I bought a 2" SunPro electric oil pressure gauge and gutted it. The + and sender terminals were the same distance apart as the original AMP gauge. I did have to drill one hole through the cluster housing and through the printed circuit for the ground wire.

Next I turned my attention to the printed circuit. I was a little too rough when I removed the connector and damaged two of the pins. I read that I could use a paper clip to reinforce the pins so I thought I'd give it a try. I coated the inside of the pins with flux, inserted the paper clip and soldered the pins. I cut both ends of the paper clip off and ground a little on the back side so the repair would clear the cluster housing when the board was reattached.

The right two pins were loose.

You can see the repaired pins on the back side.

Then, I cleaned and repainted the inside of the cluster housing and made some new gaskets for the idiot light/turn signal lenses.

I've been working on the gauge cluster. I'm pretty much done with what I can do myself. I still need to have the fuel, temp gauges as well as the speedo checked for calibration and buy a solid state voltage limiter.

Since the car didn't come with an oil pressure gauge, I wanted to install one. However, I didn't want any gauges mounted in pods up under the dash either.(I don't really like that look) I also wanted to keep the idiot light. There wasn't room in the housing for a gauge and the light in the same place. I was planning on doing away with the AMP gauge anyway so I decided to install an oil pressure gauge in its place. If I think I really need to monitor the charging system, I can install a volt meter in the console ashtray. That way it can be hidden.

I bought a 2" SunPro electric oil pressure gauge and gutted it. The + and sender terminals were the same distance apart as the original AMP gauge. I did have to drill one hole through the cluster housing and through the printed circuit for the ground wire.

Next I turned my attention to the printed circuit. I was a little too rough when I removed the connector and damaged two of the pins. I read that I could use a paper clip to reinforce the pins so I thought I'd give it a try. I coated the inside of the pins with flux, inserted the paper clip and soldered the pins. I cut both ends of the paper clip off and ground a little on the back side so the repair would clear the cluster housing when the board was reattached.

The right two pins were loose.

You can see the repaired pins on the back side.

Then, I cleaned and repainted the inside of the cluster housing and made some new gaskets for the idiot light/turn signal lenses.

Last edited:

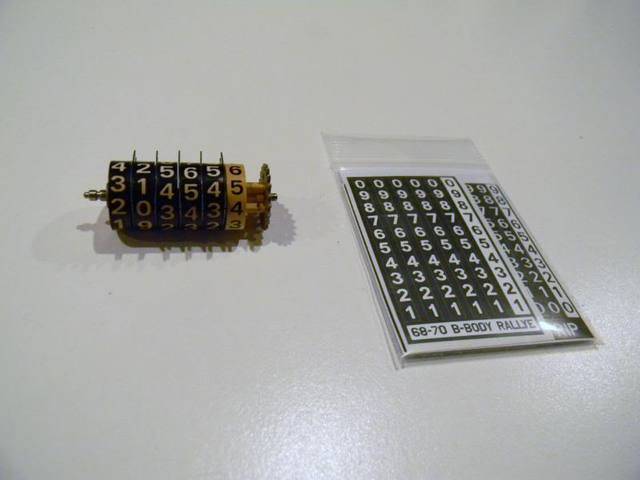

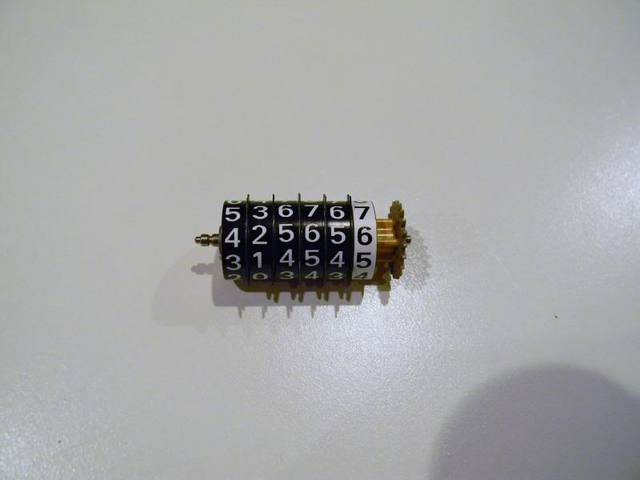

I bought an odometer reface kit from Whitegauges.net. They didn't list a reface kit for a 68 Dart so I bought one for a standard E-body dash. The size of the overlays was correct but the Dart's odometer rotates in the opposite direction. The odometer would have been showing less and less miles. They then sent me an E-body Rallye dash kit as well as a B-body Rallye dash kit to try. The E-body kit worked perfectly.

before

after

I stripped the paint off of the gauge faces and painted them white. Then I installed a white reface kit. I'm still not sold on this look. This might just be temporary.

Here is the back side of the oil pressure gauge.

The dash frame had a rusty section on the lower right side.

I cut out the bad section and made a patch. I don't have the capability to weld in the patch so I'm off to my father-in-law's house this afternoon for him to help me with it.

before

after

I stripped the paint off of the gauge faces and painted them white. Then I installed a white reface kit. I'm still not sold on this look. This might just be temporary.

Here is the back side of the oil pressure gauge.

The dash frame had a rusty section on the lower right side.

I cut out the bad section and made a patch. I don't have the capability to weld in the patch so I'm off to my father-in-law's house this afternoon for him to help me with it.

Last edited:

2fine69s

69 340-6pak Rag Top

Man great work on the dash. This type of work is very time consuming, and believe me I know where your coming from, but don't back down its looking awesome. Your thinking things through before you jump in to it, and thats 100% the right thing to do. Let me know if I can help in any way,

Martin

Martin

rlevs

Well-Known Member

okay great work on this car. now the funny part i just found this car for sale and here is the add

http://www.cars-on-line.com/56627.html

http://www.cars-on-line.com/56627.html

I wonder how long those adds stay around? You would think they'd go away at some point. I didn't pay anywhere near that price for it. The guy I bought it from got it running, put a new gas tank and sender in it and put it up for sale. It sat for a couple years and he needed the room. He sold it to me at a loss. He threw in the GTS hood and a replacement windshield too.

2fine69s

69 340-6pak Rag Top

How did your dash turn out? Anything new new on the car?

Martin

Martin

The powder coater called me last week so I went and had a look at the parts he had done. He's still working on the front seat frames and the K-member. I gave him the dash frame to blast. As soon as I get that back I can start the assembly.

I sent out all the switches to JS Restorations to be rebuilt. They are done and should arrive here tomorrow. I still have to buy a new upper pad, send the radio out to be converted to FM and figure out what to do about the dash bezels. Repops are very expensive and I hear they fit really bad.

To keep the project moving forward, I started the steering column. It's almost done. I'll post some pics as soon as it's finished.

I sent out all the switches to JS Restorations to be rebuilt. They are done and should arrive here tomorrow. I still have to buy a new upper pad, send the radio out to be converted to FM and figure out what to do about the dash bezels. Repops are very expensive and I hear they fit really bad.

To keep the project moving forward, I started the steering column. It's almost done. I'll post some pics as soon as it's finished.

2fine69s

69 340-6pak Rag Top

How did the steering column turn out? Your killing me with suspense!The powder coater called me last week so I went and had a look at the parts he had done. He's still working on the front seat frames and the K-member. I gave him the dash frame to blast. As soon as I get that back I can start the assembly.

I sent out all the switches to JS Restorations to be rebuilt. They are done and should arrive here tomorrow. I still have to buy a new upper pad, send the radio out to be converted to FM and figure out what to do about the dash bezels. Repops are very expensive and I hear they fit really bad.

To keep the project moving forward, I started the steering column. It's almost done. I'll post some pics as soon as it's finished.

I haven't felt like working on it lately. The lower steering column brackets are kicking my rear. They are heavily pitted. I tried just spraying the gloss black paint really heavy but that didn't work. I stripped them back to bare metal and put three coats of high build primer on them. I sanded them last night and applied two more coats of high build. They should just need one more light sanding before the gloss black.

I painted the lower steering shaft but had a problem getting it through the new lower bearing I'm using. I had to strip some paint off of it to get it into the bearing. Now I have to repaint a couple inches of the shaft. I'll paint that this weekend too.

I got the seat frames back from the powder coater. I took the frames, seat covers and new foam to the upholstery shop. They are backed up until late March. I'm in no hurry for them so that's fine. They are getting done now because I didn't want those old nasty things in my house.

I also sent out one of my parking light housings to have an LED kit made for it. I'll post some pics when I get it back.

I painted the lower steering shaft but had a problem getting it through the new lower bearing I'm using. I had to strip some paint off of it to get it into the bearing. Now I have to repaint a couple inches of the shaft. I'll paint that this weekend too.

I got the seat frames back from the powder coater. I took the frames, seat covers and new foam to the upholstery shop. They are backed up until late March. I'm in no hurry for them so that's fine. They are getting done now because I didn't want those old nasty things in my house.

I also sent out one of my parking light housings to have an LED kit made for it. I'll post some pics when I get it back.

Well I finally got the steering column done. I'm still working on the steering wheel. The horn ring is pitted so I'll have to fugure out what to do there. I'm sure rechroming pot metal isn't cheap.

Here are some "before" pictures of the column. Obviously there was a moisture issue in the interior for awhile.

I soaked the column jacket, inner tube and lower steering shaft in acid to clean them up. The car originally had power steering but I'm converting it to manual. The replacement K-member I bought came with a lower steering shaft and coupler from a manual steering car. I separated the inner and outer steering shafts and installed the manual steering shaft in place of the original.

The inner tube was heavily pitted. Instead of trying to sand out the pits, I just painted it with stainless steel paint. Then I turned my attention to the lower bearing. A replacement stock style bearing is around $85. I bought an insert bearing for $12 online. It took a little time to figure out a way to get it to work. Basically I had to grind about 3/16" off the bottom of the inner tube and use the original plastic lower bearing as a bushing.(the internal metal parts of the bushing were removed and the plastic was modified slightly) Here is what I came up with.

The turn signal switch is still good so I reused it. The wiring connecter was broken however so I purchased a new one online. The mounting brackets were heavily pitted so I had to spray them with high build primer and sand them before painting them gloss black. The upper pieces of the column as well as the column jacket were sprayed with Rustoleum fine texture.

Here are some "before" pictures of the column. Obviously there was a moisture issue in the interior for awhile.

I soaked the column jacket, inner tube and lower steering shaft in acid to clean them up. The car originally had power steering but I'm converting it to manual. The replacement K-member I bought came with a lower steering shaft and coupler from a manual steering car. I separated the inner and outer steering shafts and installed the manual steering shaft in place of the original.

The inner tube was heavily pitted. Instead of trying to sand out the pits, I just painted it with stainless steel paint. Then I turned my attention to the lower bearing. A replacement stock style bearing is around $85. I bought an insert bearing for $12 online. It took a little time to figure out a way to get it to work. Basically I had to grind about 3/16" off the bottom of the inner tube and use the original plastic lower bearing as a bushing.(the internal metal parts of the bushing were removed and the plastic was modified slightly) Here is what I came up with.

The turn signal switch is still good so I reused it. The wiring connecter was broken however so I purchased a new one online. The mounting brackets were heavily pitted so I had to spray them with high build primer and sand them before painting them gloss black. The upper pieces of the column as well as the column jacket were sprayed with Rustoleum fine texture.

Last edited:

Just a small update. There is a company called "Illumin8s" that sells a multi function LED kit for Challengers, Cudas, Chargers and some GM products. I thought these LEDs would look great on my Dart so I contacted the owner. I sent him one of my parking light housings and he designed a kit for me. He will be adding this kit to the others that he sells.

Here is what the LED looks like when it's mounted. There is no modification to the stock wiring. It just plugs into the stock socket in the housing.

Here is a video showing how these LEDs work.

[ame="[MEDIA=youtube]nactAwM4Wtw[/MEDIA]"]Illumin8s - YouTube[/ame]

I've been trying to deside how I want these to function. The stock headlight switch is setup so the parking lights are only on in the first possition. The parking lights go out when the headlights are on. I found a post on this site that shows how to rewire the parking lights so they stay on with the headlights. I thought about doing this but I think I came up with something that I like even better.

What I think I'm going to do is wire the parking lights up to an ignition hot wire so they come on whenever the key is in the "RUN" possition. They will act as a daytime running light this way. I did have a concern that since they are up so high in the grill, that they might be too bright at night. That's why I'm going to run the power wire through another toggle switch. I'm going to find another switch and bezel, and install it in the dash inplace of the cigarette lighter. This way, if the LEDs are too bright at night, I can switch them off.

Here is what the LED looks like when it's mounted. There is no modification to the stock wiring. It just plugs into the stock socket in the housing.

Here is a video showing how these LEDs work.

[ame="[MEDIA=youtube]nactAwM4Wtw[/MEDIA]"]Illumin8s - YouTube[/ame]

I've been trying to deside how I want these to function. The stock headlight switch is setup so the parking lights are only on in the first possition. The parking lights go out when the headlights are on. I found a post on this site that shows how to rewire the parking lights so they stay on with the headlights. I thought about doing this but I think I came up with something that I like even better.

What I think I'm going to do is wire the parking lights up to an ignition hot wire so they come on whenever the key is in the "RUN" possition. They will act as a daytime running light this way. I did have a concern that since they are up so high in the grill, that they might be too bright at night. That's why I'm going to run the power wire through another toggle switch. I'm going to find another switch and bezel, and install it in the dash inplace of the cigarette lighter. This way, if the LEDs are too bright at night, I can switch them off.

Last edited:

My new upper dash pad showed up yesterday. I quickly checked the fit and it seems good. I got the dash frame painted but I'm not happy with it. I ended up sanding the top back down to bare metal. I've got a layer of filler spread across the top and have started sanding it back down. I should have it painted again this weekend.

Here's an update on the dash. So far everything is going OK. Not perfect but OK. I had the frame blasted and the patch finish welded.

I smoothed out the repair with filler and sprayed the frame with Rustoleum fine texture paint. I wasn't happy with how the top looked so I stripped it back to bare metal, put a coat of filler on and sanded it back down. It looks much better now.(I thought the minor pitting would be hidden by the textured paint but it wasn't)

I cleaned and sprayed the lower pads with SEM Landau Black. If repros were available I'd replace them. There is some waviness in the vynal but there are no cracks. The upper pad fit decent. It should look good in the car. There is a slight hump in the middle that isn't laying flat against the frame. The ash tray was hanging really low. I ended up adding some spacers between the frame and the ash tray mount to raise it up about an 1/8". It tucks up nicely now.

I cleaned up the main dash harness and replaced some ends that were chewed up by mice. Overall the harness was in really good shape. The new speakers fit nicely. There is plenty of clearance for the heater controls. I had to add two layers of foam to the top of the bracket to take up the gap between the bracket and the frame.

I'm pretty much at a stopping point right now. I need to send the radio off for an FM conversion and I need to buy new dash bezels.

I'm not happy with the white gauge overlays. The vinyl didn't stick to the raised letters/numbers on the upper panel. I think I'm going to machine off all the raised sections, smooth them out flat and then reinstall the white gauge face. It looks OK in the light but when the dash lights are on, it really looks bad.

I smoothed out the repair with filler and sprayed the frame with Rustoleum fine texture paint. I wasn't happy with how the top looked so I stripped it back to bare metal, put a coat of filler on and sanded it back down. It looks much better now.(I thought the minor pitting would be hidden by the textured paint but it wasn't)

I cleaned and sprayed the lower pads with SEM Landau Black. If repros were available I'd replace them. There is some waviness in the vynal but there are no cracks. The upper pad fit decent. It should look good in the car. There is a slight hump in the middle that isn't laying flat against the frame. The ash tray was hanging really low. I ended up adding some spacers between the frame and the ash tray mount to raise it up about an 1/8". It tucks up nicely now.

I cleaned up the main dash harness and replaced some ends that were chewed up by mice. Overall the harness was in really good shape. The new speakers fit nicely. There is plenty of clearance for the heater controls. I had to add two layers of foam to the top of the bracket to take up the gap between the bracket and the frame.

I'm pretty much at a stopping point right now. I need to send the radio off for an FM conversion and I need to buy new dash bezels.

I'm not happy with the white gauge overlays. The vinyl didn't stick to the raised letters/numbers on the upper panel. I think I'm going to machine off all the raised sections, smooth them out flat and then reinstall the white gauge face. It looks OK in the light but when the dash lights are on, it really looks bad.

Last edited:

-