You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

69 Dart GT Conv. 340-6pak

- Thread starter 2fine69s

- Start date

-

2fine69s

69 340-6pak Rag Top

Hey Leanna,

Girl you have an eye for detail. There bolt in bars, so maybe it won't be to bad.

Later,

Martin

Girl you have an eye for detail. There bolt in bars, so maybe it won't be to bad.

Later,

Martin

Hey Leanna,

Girl you have an eye for detail. There bolt in bars, so maybe it won't be to bad.

Later,

Martin

Good deal! But heyyyy it's my job. :-D I gotta take care of you guys.

Lookin good Martin...

Cant tell if Im startin to get jealous or just very envious!?

Best to you and the family.

Cant tell if Im startin to get jealous or just very envious!?

Best to you and the family.

2fine69s

69 340-6pak Rag Top

Now Douglas,

Your riding and I've been sitting for 7 years, guess who's jealous?

Your riding and I've been sitting for 7 years, guess who's jealous?

2fine69s

69 340-6pak Rag Top

Got the torsion bars back today and they look awesome. I need you guys and gals to help once more with a decision. I took the transmission case to the coater today, and I need to finalize the color by Monday. Since my car is long from being "Restored" and more "Restified", I was thinking of changing the usual trans color. Most use Black, Dull Silver, or Aluminum as a color choice. I was thinking Hemi Orange with Silver bolts and a Chrome deep pan. What would you guys vote for?

Martin

Martin

Last edited:

Unless you're going to have that puppy sitting at the car show with a half dozen mirrors under it, a lot of beauty work on your transmission will only be visible to you. Just my two cents though ... :-D

The torsion bars look great by the way!

The torsion bars look great by the way!

2fine69s

69 340-6pak Rag Top

Unless you're going to have that puppy sitting at the car show with a half dozen mirrors under it, a lot of beauty work on your transmission will only be visible to you. Just my two cents though ... :-D

The torsion bars look great by the way!

I get your drift girl,

This is my last build and although at some point money could be an issue,I really didn't want to say "I wish I had done that", know what I mean?

BrokenTool

Well-Known Member

What a great thread, love the car and what you are doing with it. I too have a '69 but it's a hard top, I am travelling somewhat on the same road in the reincarnation process with a few more curves. Seeing that the Dart started out as something else then what it is today. Again great workmanship and attention to detail.

2fine69s

69 340-6pak Rag Top

Thanks BT,

I really appreciate it

Martin

I really appreciate it

Martin

2fine69s

69 340-6pak Rag Top

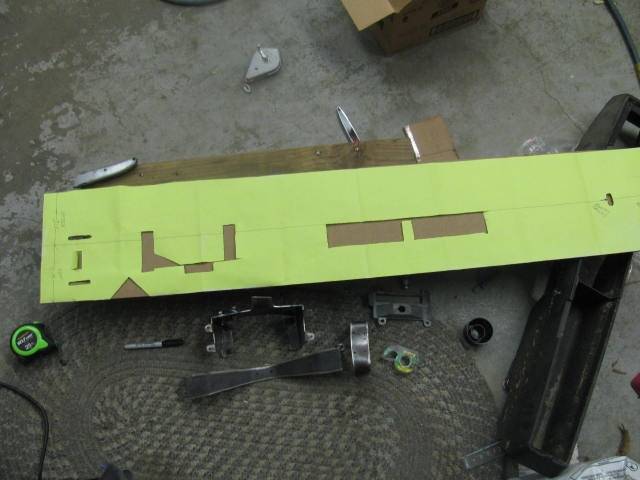

Well today I started re-assembly of the front suspension. Got the beefed up LCA's on, as well as the Hotchkis struts. The Schumaker engine mounts are only finger tight, and the torsion bars are in for fit test only. I'm a little concerned about the oil pan/K-member clearance, but I'll have to wait until the engine/tranny jig get here from US Car Tool to check it and the headers. The Flaming River steering gear should be here by Tuesday, then I'll mount it. Put as much as I could together, then moved on to the console brackets install. Since I've already coated the bottom of the car, I'll be bolting in these so as not to burn the bottom coating when welding. Wish me luck,

Martin

View attachment 1714677270

View attachment 1714677271

Martin

View attachment 1714677270

View attachment 1714677271

Last edited:

Captainkirk

Old School Mopar Warrior

Great progress! Did you end up powder coating the K-frame?

2fine69s

69 340-6pak Rag Top

Hey Cap,

No, I had already painted it before Tarheel Coatings opened their doors. Since their opening, I have taken them everything that needed color, other than Go Green. I used Acrylic Enamel with a hardner, maybe it'll hold up. The trans casing and other mis. pieces should be back this week.

No, I had already painted it before Tarheel Coatings opened their doors. Since their opening, I have taken them everything that needed color, other than Go Green. I used Acrylic Enamel with a hardner, maybe it'll hold up. The trans casing and other mis. pieces should be back this week.

Captainkirk

Old School Mopar Warrior

K-frame looks GREAT! Very nice work so far!

2fine69s

69 340-6pak Rag Top

Got the new Flaming River steering gear today. Assuming the oem pitman arm is the same (and I was told it was), I should mount it on the K member on Friday. Gonna be a couple of weeks before the K member jig is ready, so I'll move forward with mounting the console and shifter then installing the seats for a fit test.

View attachment 1714678097

View attachment 1714678097

2fine69s

69 340-6pak Rag Top

Got the trans casing back from the coaters today. I had it done in Hemi Orange. Gotta deep Chrome Mopar Performance Pan and pick up. All the bolts will be done in silver, they're not ready yet.

Wow, it's too bad they didn't clean up the casting on the bellhousing first ... got any close ups?

2fine69s

69 340-6pak Rag Top

Hey girl, nope and nope they didn't clean the castings up, but my bad, I didn't tell them to. Guess I had too many irons in the fire when I took it to them. Thanks for keeping me on my toes...Wow, it's too bad they didn't clean up the casting on the bellhousing first ... got any close ups?

You're welcome, but in my opinion you shouldn't HAVE to ask. Good powder coating jobs are 95% prep.

2fine69s

69 340-6pak Rag Top

Well I finished mounting the console brackets that I got from Redfish (thanks Ben), the console is in and all works smoothly. Now its time to rip the console back out for a facelift on it with all new top plates, shifter, lens, and slider. It will be white with woodgrain tops the next time you see it.

View attachment 1714680221

View attachment 1714680221

2fine69s

69 340-6pak Rag Top

Well all and all, Christmas week was relatively productive. I got a set remote control QTP cut outs from Santa. In the shop, I put the Dillinger UCA's on along with painting and installing the new shocks. The Motor/Tranny/K member Jig came in and its together now. Hopefully the transmission will be together this week and I can start mounting all to the jig.

View attachment 1714683539

View attachment 1714683539

2fine69s

69 340-6pak Rag Top

I had a couple of minutes today, and decided to get out my Christmas present from the family. QTP remote cut outs. These things are trick, if they work as good as they look, we'll be in good shape. Anyone run these before? I've been buying parts for many years now, so some have been sitting up for a while. Case in point the Turbo Action 10" converter, it had dust on and in the input snout from the crack openings in the top of the box, just to ease my mind, I took it to be flushed today, I'll pick it up tomorrow. I'm hoping to have the transmission back this week...

I'll be laying the wiring harness in this week, and pulling wire for the cut outs and speakers also.

I'll be laying the wiring harness in this week, and pulling wire for the cut outs and speakers also.

Last edited:

2fine69s

69 340-6pak Rag Top

Well today I mounted my electric oil sending unit and mechanical oil pressure gauge. My instrument cluster gauges are of course electrical, and I wanted a little feel good back up plan for the oil pressure. I used an 1/8" brass tee and 2) 1/8 x 45 degree brass adapters. This allowed me to mount the 1 1/2" VDO oil pressure gauge upwards and slightly towards the right side of the car. I should be able to see it over the right fender. My only concern is the clearance of the oil sending unit to the firewall. Because I now have an oil pressure gauge in my cluster, I have to use the larger bell type sending unit. It is angled upwards and slightly towards the firewall. I'll have to wait until I sit the car down on the drive train to check for clearance. If I do end up with a clearance issue, I'll just take the mechanical gauge out and just use the bell sending unit vertical.

View attachment 1714684790

View attachment 1714684792

View attachment 1714684790

View attachment 1714684792

Been a while since I flipped thru...Great work and some great choices! I like the idea of the mech oil psi gauge and the elec. Looks like you might be able to turn the "T" back counter clockwise to help with the firewall "issue"?? If so could you get a "locknut" to thread onto the "T" to lock into position??

Great work!

Great work!

Looking good Martin!

Lets catchup later this weekend... sounds like youre making some major progress.

Lets catchup later this weekend... sounds like youre making some major progress.

-