Correct that’s why if I buy from fbo or from dui I plan to get the kit with a distributor and they dial them in. Just back and forth between these kits.Also worth noting - HEI isn't the only ignition with variable dwell. The Bosch systems used on most early '80s European cars, Ford's TFI ignition module (the one that replaced the Duraspark), and pretty much everything fuel injected where the EFI computer had timing control integrated all used variable dwell. Variable dwell also removes much of the need to match the ignition box to the RPM range (at least until you get to the point you need a CDI) since the box can change its dwell with RPM. You won't see serious overheating issues with a properly working street box on the street, but try using a gold ignition box and its ballast in stop and go traffic and you'll run into heat issues. A good quality variable dwell ignition can pull off gold box behavior at high RPM and street box behavior at idle.

That said, it's an incremental improvement, and may not be a difference for your build. I would not bother swapping the distributor if you want HEI unless your distributor is damaged beyond repair - wiring a good quality module to your distributor and possibly swapping the coil are all it takes. And if you already have the advance curve dialed in, swapping the distributor means you now need to copy your advance curve into your new distributor to get it to run as well as the old one.

And there's a reason I put "have the advance curve dialed in" in bold. The right advance curve is a lot more important than the HEI vs Mopar ignition debate.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electronic ignition upgrade.

- Thread starter rymor92

- Start date

-

From what I have read and experienced with my 340 for 54 years is that ignition timing and advance curve are paramount to a good running engine. Once the spark is stable at all RPM's the engine will see, the power is in the timing curve. The 340 seems to like 34° mechanical advance for best 1/4 mile MPH. From there, use the advance plate with the least advance or weld to shorten. I use an 11° advance plate (distributor advance degrees). This is 22° crank advance, so initial advance is 12° for a total of 34°. The rest is in the advance springs to eliminate any detonation. The quicker the advance, the more power to the point where advance is optimum for the combustion chamber design and cam.

I got my stock 340 to a 13.48 @ 105.38 with a 3300 lb '68 Formula S FB using this approach. Could have done a better ET with more tire and gear (3.55), but never went that way.

I got my stock 340 to a 13.48 @ 105.38 with a 3300 lb '68 Formula S FB using this approach. Could have done a better ET with more tire and gear (3.55), but never went that way.

Newbomb Turk

Well-Known Member

Rymor,

Take no notice of Newbomb Turk & his superb ignorance. If he actually knew anything about ign, he would know that HEI is an improvement. Look at FACTS.

[1] Over the decades, spark plug gaps have increased. Why? Because the greater exposure of the mixture to the bigger spark is more likely to ensure combustion takes place.

[2] GM recommended 060 plug gaps for most engines, some had 080 gaps. I have run 1/8"for the hell of it...

[3] Variable dwell [ VD ] is MOST important & more so as the number of cyls increase [ for an 8 cyl engine ]. I suspect the reason Chrys did not have VD is that the Motorola # MC3334 IC was not available when the ECU was designed. The primary winding of the ign coil takes time to reach it's max current value, [ & therefore max efficiency at transferring that energy to the sec winding ]....& creating a spark. With more cyls to fire [8] from ONE coil, that critical saturation time is reduced...time to start preparing for the next spark. This is where VD comes in. Since there is more time at low rpms to saturate the coil, the dwell is reduced. Dwell being the number of degrees of crank angle [ not time like many think ] that that the coil is on. With fixed dwell on a street driven car, the coil gets very hot at idle/cruising & that shortens the life of the coil. Also, the coil windings are made of copper. The hotter they get, the higher the resistance & the less power the coil produces. At higher rpms, a VD system starts the coil current earlier so that the coil has enough time to saturate. A very clever system.

[4] You can buy HEIs for all types of engines that never originally had HEI. From many manufacturers. None of those companies are making Chrys dist to use Chrys ECUs........Hmm.

[5] Any ign system that uses a bal res is not going to produce as much ign power as a system that uses a low resistance coil & NO BAL RES. The HEI coil gets the full 12v. The Chry coil gets about 7-8 v. The HEI coils are about 0.6 ohm; they are also E core coils, much more efficient than the Chrys canister coil. The Chrys coil is about 1.5 ohms. The formula for power [ Watts ] is voltage squared divided by the resistance. It is obvious the HEI system provides much more spark energy.

[6] The Chrys system eliminated points, which gave more reliable ign & increased tuning intervals. It was good in that respect. It did NOTHING to improve spark energy. Same coil, same bal res used as in the points system. Hence the limited 0.035 plug gap.

See below. HEI has 40% more voltage output & 85% higher energy level.

View attachment 1716235888

lol. You sound like a carnival huckster trying to pimp out garbage.

Again, big gaps are bullshit unless you live and die by magazine articles and book writers.

To the OP…just buy the HEI. It’s what you want. But put the engine on a dyno with both ignition systems and see what you get for a power gain. I say zero.

And then play with plug gaps. My bet is over .040 you won’t find a thing and the gain from .035 to .040 won’t be much either.

You can test all this stuff and see who the bullshitters are. Here’s a dead giveaway. If the constantly post other people’s testing and results then you know they are just little mocking birds, repeating nonsense.

Newbomb Turk

Well-Known Member

Also worth noting - HEI isn't the only ignition with variable dwell. The Bosch systems used on most early '80s European cars, Ford's TFI ignition module (the one that replaced the Duraspark), and pretty much everything fuel injected where the EFI computer had timing control integrated all used variable dwell. Variable dwell also removes much of the need to match the ignition box to the RPM range (at least until you get to the point you need a CDI) since the box can change its dwell with RPM. You won't see serious overheating issues with a properly working street box on the street, but try using a gold ignition box and its ballast in stop and go traffic and you'll run into heat issues. A good quality variable dwell ignition can pull off gold box behavior at high RPM and street box behavior at idle.

That said, it's an incremental improvement, and may not be a difference for your build. I would not bother swapping the distributor if you want HEI unless your distributor is damaged beyond repair - wiring a good quality module to your distributor and possibly swapping the coil are all it takes. And if you already have the advance curve dialed in, swapping the distributor means you now need to copy your advance curve into your new distributor to get it to run as well as the old one.

And there's a reason I put "have the advance curve dialed in" in bold. The right advance curve is a lot more important than the HEI vs Mopar ignition debate.

Have you ever run a Gold Box on the street? I haven’t, but I have 5 or 6 boxes out there on running street cars that say the same thing…you can’t run them on the street or they over heat. I’ve never seen it.

Same with fuel pumps. There are some that say they aren’t for “street duty” but I’ve never seen that be the case either.

BillGrissom

Well-Known Member

Best to detail your engine and car whenever asking an engine question. I had to scroll down to post #46 to learn. Easiest is the 8-pin GM HEI module (1985-95) with their coil and cable which connects the two. Many posts and TrailBeast here use to sell as a kit for those who don't go to salvage yards. The Mopar e-distributor can trigger it. Losing the ballast is one advantage. Mopar ECU's tend to fail and replacements today are suspect.

For those with a points distributor, the Ningbo "ready-to-run" HEI distributor is simplest, paired with an e-core coil. Check Steve White Performance on ebay. A kit should be <$100, but only avail for SB & BB, not slant.

For those with a points distributor, the Ningbo "ready-to-run" HEI distributor is simplest, paired with an e-core coil. Check Steve White Performance on ebay. A kit should be <$100, but only avail for SB & BB, not slant.

I had similar thinking at one time.Not going for sale. It’s going up on a stand. For possible future use. I bought this car just to replace everything in it for better performance and handling but keep the classic original look. All original clean car.

View attachment 1716235728

View attachment 1716235729

View attachment 1716235730

Eventually I learned the Chrysler team was a lot smarter and knowledgable than most enthusiasts, and that includes many racers. (On the other hand I noticed class racers tended to pay attention to factory info and put it to use. But I digress)

Here's my time and money saving suggestee ons to meet yer goals, or at least get a good start:

1. Using a timing light and tach, measure and document the mechanical timing.

2. Disconnect the OSAC. All that involves is connecting the distributor vacuum advance directly to the timed port on the carb. Go drive it and it ought to be a hell of a lot more responsive to throttle. Now you have a baseline, Go to the drag strip and start getting numbers.

3. See if there is a front anti-sway bar on the car. If not, put one on. That will require either changing the lower control arms or buying one of the bars that has a well thought out and tested way of attaching to non-tabbed LCAs. That will change the percieved and actual handling more than any other single change. After that make sure there is enough negative camber and positive caster for the radial tires, reset toe.

We see there's already aftermarket intake and so with whatever other changes are going on, start tuning it. This won't be a factory. This is tuning for performance.

Last edited:

If the Mopar box doesn't vary dwell, then tell me, how does it retard timing at high RPM? Because it DOES.

MadScientistMat

Well-Known Member

- Joined

- Mar 6, 2008

- Messages

- 596

- Reaction score

- 199

The Mopar box's dwell is not constant either. It's a very simple design from an era where transistors were expensive and using an integrated circuit in a module would have been unthinkable. (At one point, Chrysler patented a voltage regulator design, which they never used, that had only one transistor because a second one would drive up the cost.) The way it behaves is that it normally keeps the transistor in an on state. When it receives a pulse from the distributor sensor, this shuts off the transistor (like opening the points) for a duration controlled by a timer circuit. The circuit that detects the pulse has a very short response time - but it's long enough that it retards the timing a tiny bit. Since it's a somewhat fixed amount of time that delays the spark, but there's less overall time in between sparks, you get a measurable amount of timing retard at high RPM.If the Mopar box doesn't vary dwell, then tell me, how does it retard timing at high RPM? Because it DOES.

Only real ways around this are to make a more sensitive trigger circuit, which would have meant more complexity and cost, and possibly a risk of sparking in response to electrical noise. Modern computer controlled ignitions either have a variable that predicts the amount of delay, or have it factored into a computerized curve that's a bit more complicated than anything you can do with a mechanical advance.

The race modules have a shorter timer circuit - if the off time is too long, you don't get enough dwell to get decent spark energy at high RPM. Conversely, a shorter off time and lower resistance ballast resistor makes for more heat at low RPM. I haven't personally investigated Chrysler's report that their ignition combinations tailored for high RPM overheat at prolonged operation below 2000 RPM, but it's consistent with the way they operate. The module is tuned for an optimized dwell at one particular RPM, and the ballast resistor limits the current below that point.

I know how it works. I was pointing out that someone who says the Mopar unit doesn't change dwell is WRONG.The Mopar box's dwell is not constant either. It's a very simple design from an era where transistors were expensive and using an integrated circuit in a module would have been unthinkable. (At one point, Chrysler patented a voltage regulator design, which they never used, that had only one transistor because a second one would drive up the cost.) The way it behaves is that it normally keeps the transistor in an on state. When it receives a pulse from the distributor sensor, this shuts off the transistor (like opening the points) for a duration controlled by a timer circuit. The circuit that detects the pulse has a very short response time - but it's long enough that it retards the timing a tiny bit. Since it's a somewhat fixed amount of time that delays the spark, but there's less overall time in between sparks, you get a measurable amount of timing retard at high RPM.

Only real ways around this are to make a more sensitive trigger circuit, which would have meant more complexity and cost, and possibly a risk of sparking in response to electrical noise. Modern computer controlled ignitions either have a variable that predicts the amount of delay, or have it factored into a computerized curve that's a bit more complicated than anything you can do with a mechanical advance.

The race modules have a shorter timer circuit - if the off time is too long, you don't get enough dwell to get decent spark energy at high RPM. Conversely, a shorter off time and lower resistance ballast resistor makes for more heat at low RPM. I haven't personally investigated Chrysler's report that their ignition combinations tailored for high RPM overheat at prolonged operation below 2000 RPM, but it's consistent with the way they operate.

Sorry I tried!

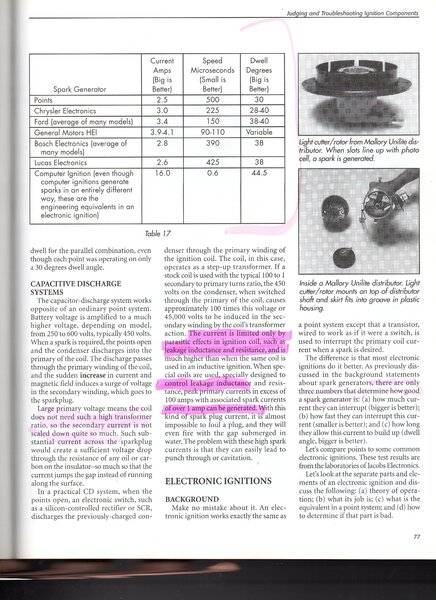

Phil Jacobs, founder of Jacobs ign systems, wrote a very good book called Performance Ign Systems. I have not used his systems, but those that have generally have positive comments such as better mileage & power.

The Chrys ign system did not fare well in his ign comparison, especially compared to HEI. Not that the Chrys ign does NOT have variable dwell; the numbers quoted are different ECUs.

The Chrys ign system did not fare well in his ign comparison, especially compared to HEI. Not that the Chrys ign does NOT have variable dwell; the numbers quoted are different ECUs.

Newbomb Turk

Well-Known Member

With a magnetic trigger, the spark retards at higher rpms due to distortion of the flux wave created by the trigger.

View attachment 1716236346

Utter nonsense. Go look up slew rate. That’s what causes timing retard

Newbomb Turk

Well-Known Member

Some want to tell that switching to a Platinum or specialty plug......or increasing the plug gap is worth nothing...

Ding Dong...

View attachment 1716236347

Post YOUR OWN results. Maybe you can’t. It’s easier (and cheaper) to read books and not test.

Again, the HEI is NOT an upgrade over the Chrysler ignition. Or the Duraspark either.

I get you’re a GM with few friends so you come here and hang out. Not everything GM was the best.

Yes, master. Your bullshit has been noted.

If I posted my results, you would claim they are unsubstantiated...& where is the proof.

So I post results from respected people, known to thousands.....

Where is YOUR proof that HEI is not better than a Chrys ECU???????????????

You are just so dumb........

I have a GM car because I like the body shape of this particular model. If it had not been made, I would still have a Chrys car, of which I have owned many.

You know nothing about me, you fool.

I am also smart enough to realise that sometimes the 'other guy' has a better product. It is the FOOL who fails to recognise this.

Chrys has great engineering, also has. That does not exclude other companies from having a better idea.

Oh, & you better contact Phil Jacobs, tell him what an idiot he is, to hand back his PhD....because only Newbomb Turk has all the answers.

If I posted my results, you would claim they are unsubstantiated...& where is the proof.

So I post results from respected people, known to thousands.....

Where is YOUR proof that HEI is not better than a Chrys ECU???????????????

You are just so dumb........

I have a GM car because I like the body shape of this particular model. If it had not been made, I would still have a Chrys car, of which I have owned many.

You know nothing about me, you fool.

I am also smart enough to realise that sometimes the 'other guy' has a better product. It is the FOOL who fails to recognise this.

Chrys has great engineering, also has. That does not exclude other companies from having a better idea.

Oh, & you better contact Phil Jacobs, tell him what an idiot he is, to hand back his PhD....because only Newbomb Turk has all the answers.

Newbomb Turk

Well-Known Member

Yes, master. Your bullshit has been noted.

If I posted my results, you would claim they are unsubstantiated...& where is the proof.

So I post results from respected people, known to thousands.....

Where is YOUR proof that HEI is not better than a Chrys ECU???????????????

You are just so dumb........

I have a GM car because I like the body shape of this particular model. If it had not been made, I would still have a Chrys car, of which I have owned many.

You know nothing about me, you fool.

I am also smart enough to realise that sometimes the 'other guy' has a better product. It is the FOOL who fails to recognise this.

Chrys has great engineering, also has. That does not exclude other companies from having a better idea.

Oh, & you better contact Phil Jacobs, tell him what an idiot he is, to hand back his PhD....because only Newbomb Turk has all the answers.

Post your numbers then. Are you that scared of being exposed as the goofball you are??

Unlike you, I don’t worship man. If someone writes a book or a bunch of articles you take them as etched in stone and then publicly hump them like gods.

One example is the Holley books. Doesn’t matter who wrote them, they always cloud carb tuning in mystery and then they preach incorrect tuning info.

It’s so sad that you have read all those books and you have done all this testing to verify the results but yet and still you don’t grasp the concept of how the Main Air Bleed functions.

Had you read Obert’s book or Taylor’s books you’d KNOW how wrong you are about that.

This is no different. I can tell you I’ve tested the HEI on the dyno and at the track. For all the leg humping on the HEI I’ve never seen a single one beat anything. Not once.

Back to the OP. He said he wanted an UPGRADE. The HEI is not an upgrade no matter how bad your feelings get hurt. It’s not.

Go peddle your nonsense somewhere else. Plenty of GM forums around that you can hang out on and lie to each other about how great ball-stud rockers are, how superior the 20and 12 bolt are. And surely you can love on the HEI with them.

As for Jacob’s, I have his book. Read it many times. I couldn’t care less what he says (or you or anyone else for that matter) if it doesn’t match my testing.

Go test something and post the results.

And let’s not forget, NHRA got hammered by some people (myself included) when they allowed DUI to advertise their HEI had more power than a mag.

Not only is that a lie, DUI and NHRA knew it was a lie.

Once more on plug gaps. I just showed a Chrysler box that won’t fire a .110ish gap very well.

Bet all you have in a running engine with a .035-.040 gap it will fire the plugs and make as much power as your beloved HEI.

Prove me wrong with Your testing, not someone else’s work.

Turk,

After reading your post #68, I have to admit I got it wrong in post #67. You are not just dumb, you are really dumb...

Not only dumb, but cannot read either.......

Not that it is any of your business, but I am on more Chrys forums than GM forums.

Might be hard for you to understand, but sometimes the 'other' guy has a better idea. The smart people take note, learn from it.......the dumb people ignore it....

And your testing.......Because NB Turk tested it [ something, anything ] it is gospel & cannot be wrong. You getting this folks?? Only believe NB Turks results.

I am ready for a laugh now so please tell us how main air bleeds work.....because you got that wrong & keep getting it wrong.

After reading your post #68, I have to admit I got it wrong in post #67. You are not just dumb, you are really dumb...

Not only dumb, but cannot read either.......

Not that it is any of your business, but I am on more Chrys forums than GM forums.

Might be hard for you to understand, but sometimes the 'other' guy has a better idea. The smart people take note, learn from it.......the dumb people ignore it....

And your testing.......Because NB Turk tested it [ something, anything ] it is gospel & cannot be wrong. You getting this folks?? Only believe NB Turks results.

I am ready for a laugh now so please tell us how main air bleeds work.....because you got that wrong & keep getting it wrong.

Kendog 170

Let the boy go !

My Rb 500 started life with that ecu. Then I upgraded to MSD. So, when it failed and got towed home 2 months later, I put it all back and it's been that way for years now. I just keep a spare ECU and ballast with me as I do in my Ragtop.What in there now is more than enough! I run a Standard lx101 in my dart sport 360. Its a hot little motor! 292 mopar purple shaft, 3.91's out back 850 thermoquad on a Victor 340 intake. 340 X-heads etc.. it's a mean machine. Doesn't miss a beat!!!

But are they? Not in his case I don't believe. As you said overkill. A points ignition in good shape with a good hotcoil and loose curve will do everything HEI will do with the exception of replacing the points "every now and again". I've done it. So have countless others. WHAT was on drag strips before electronic ignition? Yeah. Thought so. lol...........but those are improvements.

Remember, they also say that about their constant output voltage regulators. "Not for street use", but I've done it and seen tons of them on the street.Have you ever run a Gold Box on the street? I haven’t, but I have 5 or 6 boxes out there on running street cars that say the same thing…you can’t run them on the street or they over heat. I’ve never seen it.

Same with fuel pumps. There are some that say they aren’t for “street duty” but I’ve never seen that be the case either.

Save it. It won't do any good. lolSorry I tried!View attachment 1716236086

Can you point me to those two books, please?Had you read Obert’s book or Taylor’s books you’d KNOW how wrong you are about that.

Good to read real stories of some ECU's. I bought a couple of LX101 from RockAuto for $10 each probably 3 years ago? I was told(on here) they are/were junk lol.

Now there's used LX101 on here for $80

Now there's used LX101 on here for $80

What in there now is more than enough! I run a Standard lx101 in my dart sport 360. Its a hot little motor! 292 mopar purple shaft, 3.91's out back 850 thermoquad on a Victor 340 intake. 340 X-heads etc.. it's a mean machine. Doesn't miss a beat!!!

My Rb 500 started life with that ecu. Then I upgraded to MSD. So, when it failed and got towed home 2 months later, I put it all back and it's been that way for years now. I just keep a spare ECU and ballast with me as I do in my Ragtop.

-