Help!

I am worked through my first resto-mod project a 1973 Plymouth Duster and have hit a snag.

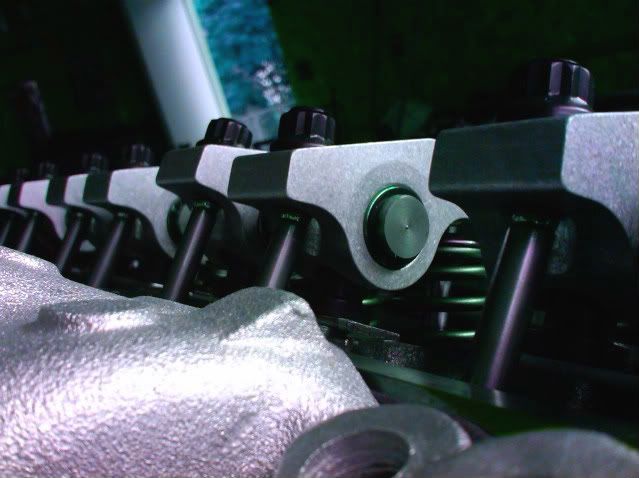

I had to purchase new heads for my chosen power plant a 5.2L Magnum bored 0.30 over, balanced and with a hotter cam (216/224 duration @ 50, 0.506 lift) and the local engine shop suggested using Chevy LS1 valve springs. I was told that they were heavier than the stock springs, would install with no modifications to the heads, and were considerably cheaper.

Now I am in the process of finishing the valve-train, and heres where the snag occurred. I was adjusting the valve lash and sheared off the last (figures) exhaust rocker bolt.

I am using OEM replacement rockers and pushrods (from Mancini Racing a good outfit to deal with). Is this my problem, do I have a defective bolt, or was I adjusting the lash incorrectly? I was following the rebuild manuals for the Magnum engine and they advised adjusting the lash following tightening down the bolts to 21 ft-lbs.

Is anyone out there running LS1 valve springs in their LA or Magnum? I was told I am the only one in this area who is scary.

Should I bite the bullet and invest in Harland-Sharp roller rockers, or is the OEM set going to work? Will I need adjustable pushrods?

Any info/advise would be greatly appreciated.

Thank you.

I am worked through my first resto-mod project a 1973 Plymouth Duster and have hit a snag.

I had to purchase new heads for my chosen power plant a 5.2L Magnum bored 0.30 over, balanced and with a hotter cam (216/224 duration @ 50, 0.506 lift) and the local engine shop suggested using Chevy LS1 valve springs. I was told that they were heavier than the stock springs, would install with no modifications to the heads, and were considerably cheaper.

Now I am in the process of finishing the valve-train, and heres where the snag occurred. I was adjusting the valve lash and sheared off the last (figures) exhaust rocker bolt.

I am using OEM replacement rockers and pushrods (from Mancini Racing a good outfit to deal with). Is this my problem, do I have a defective bolt, or was I adjusting the lash incorrectly? I was following the rebuild manuals for the Magnum engine and they advised adjusting the lash following tightening down the bolts to 21 ft-lbs.

Is anyone out there running LS1 valve springs in their LA or Magnum? I was told I am the only one in this area who is scary.

Should I bite the bullet and invest in Harland-Sharp roller rockers, or is the OEM set going to work? Will I need adjustable pushrods?

Any info/advise would be greatly appreciated.

Thank you.