daves66valiant

68 Dart 340/727:66 Signet Vert 340/5spd: 68 D100

Okay guys this is it. I finally got started on the install of the Keisler TKO-500 5-speed conversion kit for my 66 Valiant Convertible. Actually for right now I am using my parts car (a 66 hardtop valiant) as a dry run install without the engine until I get my car back from the painter. This way I can make mistakes without pulling my hair out. #-o It's nice not having a K-frame and suspension to deal with on this trial fitment. Plus things should be much quicker, smoother and easier once I really get started on the vert.

I will try to give detailed info and pictures as I progress through this project so it can be a future reference for other early a-body guys. The Keisler instructions are primarily for the 67 and up a-bodies but so far everything is working out okay. We'll see if this is a "no hack job" operation on the early A-body. Let the good, the bad and the ugly begin. :happy1:

Here is what I have done so far:

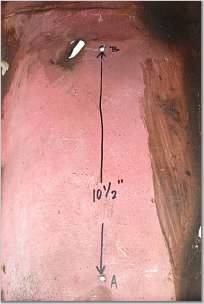

Step 1) Drilled two holes A and B for the template tracing. Underneath the car, hole A is centered directly in front of the torsion bar support rail. I drilled through the support rail and the inside floor with a 3/16" bit in the center. Hole B is centered and measured 10.5 inches forward of hole A. Figure 1, 2.

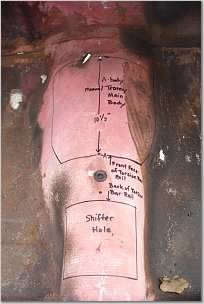

Step 2) Once holes A and B are done you can lay the supplied template over the tranny tunnel and trace out the areas that will be cut out. Figure 3.

Step 3) I used an electric die grinder and made very quick work of cutting out the template holes. I deburred the cuts as well. Figure 3.

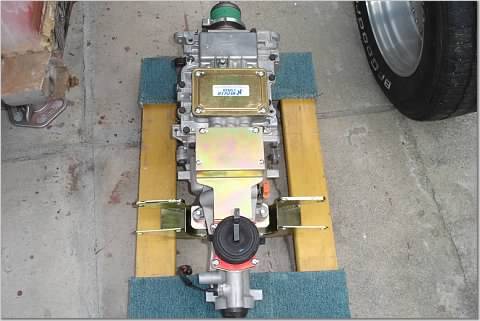

Step 4) With that done, I proceeded to mount the tranny without the engine. I ran in to a couple of problems with the tranny crossmember and the poly tranny mount. The holes on the crossmember needed to be massaged (1mm) with a file to get the holes to line up. Now the tranny mount could be bolted loosely onto to the crossmember and it slides forward and backward easily for transmission fitting adjustments once mounted. I went ahead and mounted the crossmember onto the tranny. Seemed to make things a little easier. The other problem I had was the tranny crossmember hit the torsion bar rail before I could line up all four holes of the tranny crossmember. This was a pain in the ***. Now I would have to remove everything and grind a little off the crossmember so the tranny could slide up into the tunnel enough to get all the holes to match. I don't think so, but I'm wondering what difference it would make if the car had all it's weight on the suspension/body (ie on a rack) and whether or not the crossmember would line up with the slight body flex. :scratch: Figure 4, 5, 6.

Here is what it looks like inside the car. Everything clears but it is very tight. You really have to be careful and watch out for the neutral safety switch hookup in side the tunnel. The template seemed pretty accurate. I am wondering if things will fit slightly different in the convertible. We'll see. I will continue to update this thread as I progress. Stay tuned. :wav:

I will try to give detailed info and pictures as I progress through this project so it can be a future reference for other early a-body guys. The Keisler instructions are primarily for the 67 and up a-bodies but so far everything is working out okay. We'll see if this is a "no hack job" operation on the early A-body. Let the good, the bad and the ugly begin. :happy1:

Here is what I have done so far:

Step 1) Drilled two holes A and B for the template tracing. Underneath the car, hole A is centered directly in front of the torsion bar support rail. I drilled through the support rail and the inside floor with a 3/16" bit in the center. Hole B is centered and measured 10.5 inches forward of hole A. Figure 1, 2.

Step 2) Once holes A and B are done you can lay the supplied template over the tranny tunnel and trace out the areas that will be cut out. Figure 3.

Step 3) I used an electric die grinder and made very quick work of cutting out the template holes. I deburred the cuts as well. Figure 3.

Step 4) With that done, I proceeded to mount the tranny without the engine. I ran in to a couple of problems with the tranny crossmember and the poly tranny mount. The holes on the crossmember needed to be massaged (1mm) with a file to get the holes to line up. Now the tranny mount could be bolted loosely onto to the crossmember and it slides forward and backward easily for transmission fitting adjustments once mounted. I went ahead and mounted the crossmember onto the tranny. Seemed to make things a little easier. The other problem I had was the tranny crossmember hit the torsion bar rail before I could line up all four holes of the tranny crossmember. This was a pain in the ***. Now I would have to remove everything and grind a little off the crossmember so the tranny could slide up into the tunnel enough to get all the holes to match. I don't think so, but I'm wondering what difference it would make if the car had all it's weight on the suspension/body (ie on a rack) and whether or not the crossmember would line up with the slight body flex. :scratch: Figure 4, 5, 6.

Here is what it looks like inside the car. Everything clears but it is very tight. You really have to be careful and watch out for the neutral safety switch hookup in side the tunnel. The template seemed pretty accurate. I am wondering if things will fit slightly different in the convertible. We'll see. I will continue to update this thread as I progress. Stay tuned. :wav: