I went and spent around 1.5 hours with my neighbor today to make sure she was doing ok after the death of her husband. Short viewing and funeral Saturday morning.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speedmaster Small block porting tips and results Part 1

- Thread starter pittsburghracer

- Start date

-

Good man!

I went and spent around 1.5 hours with my neighbor today to make sure she was doing ok after the death of her husband. Short viewing and funeral Saturday morning.

That's another tough thing to do. You're a good man.

PRH

Well-Known Member

I’m in the house now and I won’t say if I bought those heads bare or not till I look at them. I usually buy them complete because of the valve costs. I already had the intakes opened up for 2.08 valves by my local shop. So if there are two angles on the exhaust seats you are saying these were complete right?

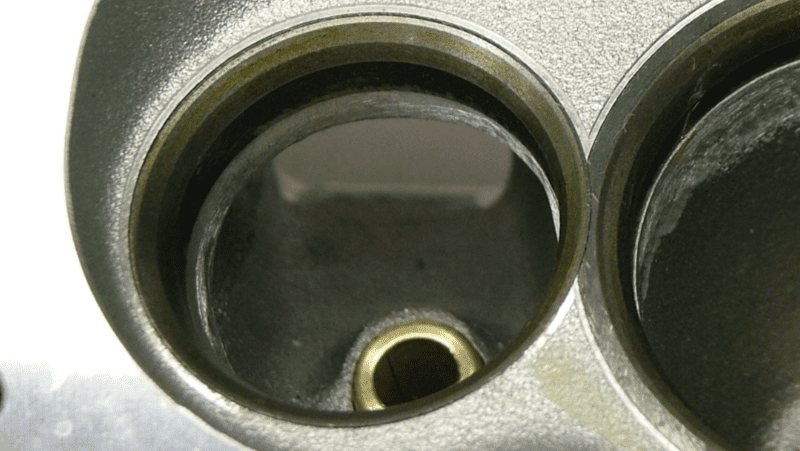

Here’s a couple pics you posted on Moparts a couple years ago.

The blank/unmachined seats in Ede heads are kind of “black” in color.

After machining they are a brighter silver grey color.

You can see the unmachined ex seat is black, and the intake seat you had cut is the silvery grey.

Also, on Ede assembled heads there is “some” amount of hand blending away of the ridge that’s under the seat.

They don’t leave it as a sharp edged cliff like it is in the pics.

Here’s a couple pics you posted on Moparts a couple years ago.

The blank/unmachined seats in Ede heads are kind of “black” in color.

After machining they are a brighter silver grey color.

You can see the unmachined ex seat is black, and the intake seat you had cut is the silvery grey.

Also, on Ede assembled heads there is “some” amount of hand blending away of the ridge that’s under the seat.

They don’t leave it as a sharp edged cliff like it is in the pics.

View attachment 1715447016

View attachment 1715447017

Ok for now I will over look that but they still leave a Frankenstein forehead type of shortside that needs pushed back and more rounded like my as cast BARE Speedmaster Head. Even after I would do a fast at home blending job it’s still a turbulent noisy port. I’m betting there is very little material taken out of a cnc’d Speedmaster exhaust port. I think we can all agree we are getting way more for less from Speedmaster

PRH

Well-Known Member

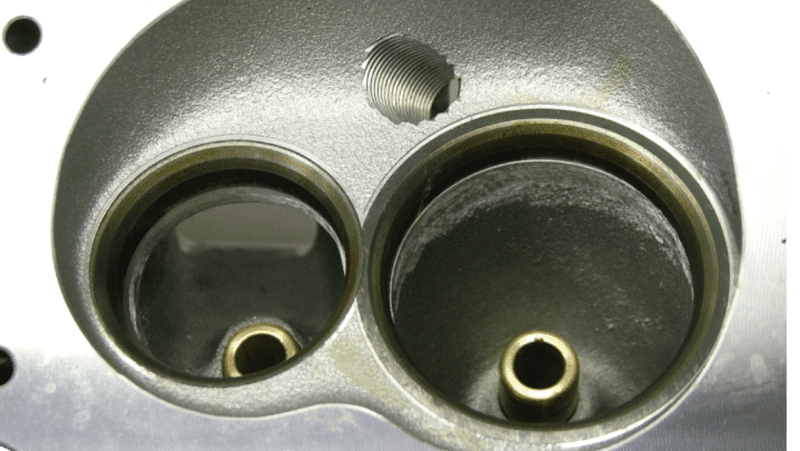

I found a pic of the assembled head seats:

PRH

Well-Known Member

Seats from assembled SM heads:

PRH

Well-Known Member

Seats from assembled SM CNC heads:

What was the casting date on this set of Speedmaster heads. By chance is this a 2015 head?

PRH

Well-Known Member

Without me having both here at the same time to try this on, it’s just speculation on my part......

But I feel like if both heads rec’d the same valve job and bowl blend....... the two heads would flow similarly.

The area where the RPM does require more work is at the port entrance/exit.

There is a noticeable ridge left where the cnc’d opening meets the as cast runner...... and that takes some time to blend away.

There is no such ridge on the SM head.

But I feel like if both heads rec’d the same valve job and bowl blend....... the two heads would flow similarly.

The area where the RPM does require more work is at the port entrance/exit.

There is a noticeable ridge left where the cnc’d opening meets the as cast runner...... and that takes some time to blend away.

There is no such ridge on the SM head.

Clean up in aisle 3!

PRH

Well-Known Member

What was the casting date on this set of Speedmaster heads. By chance is this a 2015 head?

I don’t remember....... those were here this past spring.

They were here just to be checked out....... no mods.

I don’t remember....... those were here this past spring.

They were here just to be checked out....... no mods.

Like I said in a post above I think Speedmaster has made some improvements over the years. Another example is that the intake side of a Speedmaster out of the box flows more than an Edelbrock Head even with a suck azz valve job.

without going through all the post, what year of SM are we looking at in the pictures? Mine are 2015Like I said in a post above I think Speedmaster has made some improvements over the years. Another example is that the intake side of a Speedmaster out of the box flows more than an Edelbrock Head even with a suck azz valve job.

Yep. It looks like straighten out a few things and they will be good for a nice street cruiser. It was good to hear about the exhaust side being decent. I wonder how they would act with 340 manifolds instead of headers?Like I said in a post above I think Speedmaster has made some improvements over the years. Another example is that the intake side of a Speedmaster out of the box flows more than an Edelbrock Head even with a suck azz valve job.

what car are you putting yours on? Have you ran it as it is at the strip?Yep. It looks like straighten out a few things and they will be good for a nice street cruiser. It was good to hear about the exhaust side being decent. I wonder how they would act with 340 manifolds instead of headers?

without going through all the post, what year of SM are we looking at in the pictures? Mine are 2015

Mine are dated 2017

Yep. It looks like straighten out a few things and they will be good for a nice street cruiser. It was good to hear about the exhaust side being decent. I wonder how they would act with 340 manifolds instead of headers?

Again I would match the exhaust manifolds to the head as close as possible and try it. It has to be way better than a stock head right?

I have the stock 2 barrel teen in my Swinger. I might stroke my roller teen block I have in the garage and use the heads for that. Should be an easy 400+ horse and tons of torque.what car are you putting yours on? Have you ran it as it is at the strip?

I would love to extrude hone a set of 340 manifolds and test them before and after. The prices are around $750 so no dice there.Again I would match the exhaust manifolds to the head as close as possible and try it. It has to be way better than a stock head right?

PRH

Well-Known Member

The 2017 head could very well have rec’d some tweaks from how they were in 2015.

And I don’t know what year the assembled SM heads I had here were.

That being said, the assembled SM heads I tested(whatever year they were) were no better than the assembled RPM heads, as they both came ootb.

And I don’t know what year the assembled SM heads I had here were.

That being said, the assembled SM heads I tested(whatever year they were) were no better than the assembled RPM heads, as they both came ootb.

yeah, it just doesn't make sense to do it unless your in F.A.S.T. class. TTI shorty headers are cheaper...…I would love to extrude hone a set of 340 manifolds and test them before and after. The prices are around $750 so no dice there.

A whole lot smoother but not much bigger.

73smallblock

Well-Known Member

Powerflowing (extrude hone) anything cast iron is a pain in the rear because you have to run the crap out of it, which is one of the reasons cost is so high.

While your shaping your exhaust manifold to the SM exhaust. do a little port work were you can reach and then have the inside of the exhaust manifold sand blasted.

Not as efficient as extrude hone, but much cheaper, and should help. I would be putting many a layers of duct tape to the bolting surfic.

Not as efficient as extrude hone, but much cheaper, and should help. I would be putting many a layers of duct tape to the bolting surfic.

-