IIRC from Chrysler tech videos the parts are breakaway.The '67 has metal shims, later models had plastic shims, but still the slots for the bolts are closed, does the whole dash crumple or something

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

U-joint vs pot coupler

- Thread starter Abodysrule

- Start date

-

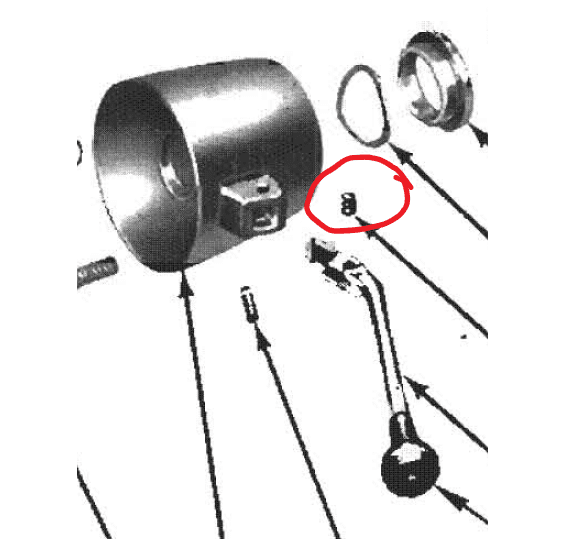

OK, I have a few questions. The little spring for the column shift lever, Moparts calls it a "anti rattle spring". It fell on the floor when I was removing the shift lever, how does that one go in?

Next question, on the back side of the gear select housing, there are these tiny hairpin clips. What on earth are those for? They don't seem to be for anything. The '67 Moparts diagram doesn't show them....strange placement, don't seem to engage anything but just clipped onto those buttresses.

Last edited:

You turn the car upside down when you put the lever back inIt fell on the floor when I was removing the shift lever, how does that one go in?

I'm pretty sure you put it in it's seat and then press the lever against it while you put the pin in

I see a hole where the long spring and plastic pin go, but I don't see a seat for the small spring, got pics?

Ah, found it. As per the '67 manual, it goes in the shifter handle around the pin. Still don't know what those hairpin clips are...anyone got that one?

Just a quick note, I'm working on a system to install the ER16 bearing (a collar to hold it and the plastic bushing for the column shaft tube). I have a rough prototype made up, so I partly reassembled the column (to make sure the shaft was installed as it would be, including the top bearing and snap rings) and I did my measurements for the U-joint. My column is just the right size, no need to shorten it. I wonder if that is yet another '67-only thing.

jos51700

Green Bearing thread connoisseur

Aren't those both full frame vehicles?My 63 Ford Econoline and my 56 Ford Pickup all had non collapsible steering shafts....

BUT

They were solid from the gear in the steering gear to the steering wheel No need for a joint of any kind. No chance of failure from a shaft sliding when it should be fixed

56 was but Econoline was unibodyAren't those both full frame vehicles

jos51700

Green Bearing thread connoisseur

Gotcha. Dodge pickups had rag joints in the steering columns even with full frames, but Dodge pickup frames kinda sucked through the early nineties too.56 was but Econoline was unibody

OK, I finished this column rebuild project. The Borgeson U-joint works great. Below are pics of my solution. I have a '67 dart, so the existing replacement column bearing kits don't fit my column. I built one using the ER-16 bearing as suggested above. I got a piece of 2 1/4" OD pipe and reamed it out to press in the bearing. On the other end, I pressed in some high density polyethylene pipe and reamed it out a bit to fit a ($4) plastic bushing for the shifter tube to ride in. I used screws into the polyethylene to hold the unit in place. To make room for the ER-16, my fabricated piece sticks out of the original column housing about 1/2". I did not need to cut my steering shaft for this to fit, it was just the right size. On my shaft, the ER-16 seated about three quarters of its width on the 1" shaft, and the remaining quarter (where the two set screws set) I used a steel shim to make sure it maintained its proper alignment with the shaft when the set screws were tightened. I replaced the original (long gone) seal on the shift tube with some polyethylene foam pipe insulation, used silicone grease to lube it (regular grease will destroy HDPE) - see green arrow on installed pic. You can also see my reverse switch post redo, it's described above, a fine thread machine screw installed from the inside of the shift tube and a nylon female threaded jacket on the outside (to engage the reverse switch and not damage it). I used Rustoleum textured paint for the finish, same as I used for my Dash.

Very nice work!OK, I finished this column rebuild project. The Borgeson U-joint works great. Below are pics of my solution. I have a '67 dart, so the existing replacement column bearing kits don't fit my column. I built one using the ER-16 bearing as suggested above. I got a piece of 2 1/4" OD pipe and reamed it out to press in the bearing. On the other end, I pressed in some high density polyethylene pipe and reamed it out a bit to fit a ($4) plastic bushing for the shifter tube to ride in. I used screws into the polyethylene to hold the unit in place. To make room for the ER-16, my fabricated piece sticks out of the original column housing about 1/2". I did not need to cut my steering shaft for this to fit, it was just the right size. On my shaft, the ER-16 seated about three quarters of its width on the 1" shaft, and the remaining quarter (where the two set screws set) I used a steel shim to make sure it maintained its proper alignment with the shaft when the set screws were tightened. I replaced the original (long gone) seal on the shift tube with some polyethylene foam pipe insulation, used silicone grease to lube it (regular grease will destroy HDPE) - see green arrow on installed pic. You can also see my reverse switch post redo, it's described above, a fine thread machine screw installed from the inside of the shift tube and a nylon female threaded jacket on the outside (to engage the reverse switch and not damage it). I used Rustoleum textured paint for the finish, same as I used for my Dash.

View attachment 1716059901

View attachment 1716059902

View attachment 1716059903

View attachment 1716059904

View attachment 1716059905

View attachment 1716059906

View attachment 1716059907

View attachment 1716059908

View attachment 1716059909

View attachment 1716059910

Thanks for the ER-16 suggestion, waaaaay better than the original bearing.

-