You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Were to find a 26" extended, double adj shock.

- Thread starter Cudafever

- Start date

-

Fisher

Old Guy with a Cool car.

I am using Rancho RS9000 truck shocks single adjustable, one dial does both compression and rebound. All the stock eliminator guys used them back in the day, 10 positions.

I did some searches that way, but couldn't figure out if the bolt size was the same let alone if the width of the rubber, was right to fit it.

Did you have any issues with this?

Also if you don't mind me asking, what of the 10 positions work best for you.

Also what was the full extend length of them shock.

When searching for cars shocks they were all in the 21" range. when i went searching for truck shock. they were listed to fit w/ model and year of truck but never showed length.

I can't afford the santuff or a like stuff, but would like to have a stiffer shock on the back that has some adj in it. But, i don't need a shock that is to short, beating it self to death also......or to long for that matter.

Did you have any issues with this?

Also if you don't mind me asking, what of the 10 positions work best for you.

Also what was the full extend length of them shock.

When searching for cars shocks they were all in the 21" range. when i went searching for truck shock. they were listed to fit w/ model and year of truck but never showed length.

I can't afford the santuff or a like stuff, but would like to have a stiffer shock on the back that has some adj in it. But, i don't need a shock that is to short, beating it self to death also......or to long for that matter.

Fisher

Old Guy with a Cool car.

I will get you the specs and part number for what i have on the duster. I bought Afco leaf springs, and mine are the 6-5/8 arch. I didnt see that they had a 4-5/8 arch spring or i would have went with that one.

Fisher

Old Guy with a Cool car.

What is the distance now on your car pin to pin sitting at ride height? Take that number and find a shock that is close to 4 inches of travel either way on compression and extending.

jimjimjimmy

lobsterman

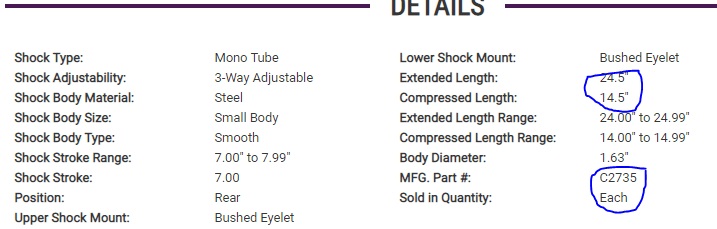

This is what i found and think will work. if i go with a single adj shock

View attachment 1715247989

this is what I use with ss springs and nitto 555 DR hooks good but wheel hop with any setting above 3 .

Questions

I have been told that a gas shock is not a good design for a drag shock?????

Also have read and been told that you need a double adj shock, because, when you want a stiffer extend, you want a softer rebound.???? Generally.?.?

I think the adj on the 9000 shock are soft to stiff together on extend and rebound.

I think on of the reason i'm have difficult time finding a 26" shock is that a true race car is slammed to the ground. NOT the stink bugs look like my is and will be again

I have been told that a gas shock is not a good design for a drag shock?????

Also have read and been told that you need a double adj shock, because, when you want a stiffer extend, you want a softer rebound.???? Generally.?.?

I think the adj on the 9000 shock are soft to stiff together on extend and rebound.

I think on of the reason i'm have difficult time finding a 26" shock is that a true race car is slammed to the ground. NOT the stink bugs look like my is and will be again

Fisher

Old Guy with a Cool car.

My shocks are the RS999114. 24.313" extended and 15.438 compressed with 8.875 inches of travel total. The tighter the setting on the shock keeps the body from rising to quickly. on the stock eliminator forums guys dial them up to setting 8 on the rear.

All i know is i got my **** working pretty decent on the street with a 275/drag radial.

All i know is i got my **** working pretty decent on the street with a 275/drag radial.

What is the distance now on your car pin to pin sitting at ride height? Take that number and find a shock that is close to 4 inches of travel either way on compression and extending.

IF this was a streetcar that might work but under full stall aka chassis load i don't what the shock to top out .

The MP rear drag shock that i have on now is 26" tall and will fit on the spring pin at full droop.

My shocks are the RS999114. 24.313" extended and 15.438 compressed with 8.875 inches of travel total. The tighter the setting on the shock keeps the body from rising to quickly. on the stock eliminator forums guys dial them up to setting 8 on the rear.

All i know is i got my **** working pretty decent on the street with a 275/drag radial.

I'm just looking for all option in my budget. MY car is not too any level of a Stock eliminator car.

what car what SS Spring.this is what I use with ss springs and nitto 555 DR hooks good but wheel hop with any setting above 3 .

This is interesting.

What or how would you describe this wheel hop.

j par

Well-Known Member

jimjimjimmy

lobsterman

what car what SS Spring.

This is interesting.

What or how would you describe this wheel hop.

70 duster 002 003 325 50 15 555 nitto extreme drag hooks hard about 1 length out it seems to unload than hook up then unload the softer settings help a lot also 549 ft lbs torque .

j par

Well-Known Member

Just my four-year-old $89 Harbor Freight flux wire welder. Keep a puddle moving keep it hot and a lot of grinding afterwards LOLThat would work if i could weld better than flinging Boogers on a piece of metal.

I just got off the phone with Speedway Motors the tallest Competition Engineering double adj shock was 24-1/2" long.

Guess i'm going to have to wait until i can set my car down and get a ride hight reading, and go from there.

The MP Drag Shock that i have on the car now are 26" from center of eye to center of eye and are full extended at droop.

Was hoping to buy these shock on my bonus check, before my wife go ahold of it.

Guess i'm going to have to wait until i can set my car down and get a ride hight reading, and go from there.

The MP Drag Shock that i have on the car now are 26" from center of eye to center of eye and are full extended at droop.

Was hoping to buy these shock on my bonus check, before my wife go ahold of it.

j par

Well-Known Member

My vote is to buy the $89 welder and some steel and a welding helmet. And stop letting everybody else having the fun with your hubby and charging you for it.I just got off the phone with Speedway Motors the tallest Competition Engineering double adj shock was 24-1/2" long.

Guess i'm going to have to wait until i can set my car down and get a ride hight reading, and go from there.

The MP Drag Shock that i have on the car now are 26" from center of eye to center of eye and are full extended at droop.

Was hoping to buy these shock on my bonus check, before my wife go ahold of it.

Yes and some day i will but not for this project.

I have a lot of rust that need to be taken care of someday and the 10,000 dollars Price tag the body man quoted me for just the rust repair in the trunk and quarter panel. i will learn how to mig weld and do it myself.....some day.

I have a lot of rust that need to be taken care of someday and the 10,000 dollars Price tag the body man quoted me for just the rust repair in the trunk and quarter panel. i will learn how to mig weld and do it myself.....some day.

j par

Well-Known Member

Again you're making my point even more...

a nice cheap welder on a nice inexpensive easy project like this sounds like a great starting point making easy brackets and learning how the puddle moves. then when you get some nice welding equipment you'll be super pro.

a nice cheap welder on a nice inexpensive easy project like this sounds like a great starting point making easy brackets and learning how the puddle moves. then when you get some nice welding equipment you'll be super pro.

I when back out with my glasses on, and a good flashlight. Turns out that my MP Drag Shocks are not 26" long but 24.5 long and 14.5 when compressed.

Same as the C.E. C2735

Even though there not a true double adj shock (Three way) I when and ordered front and rear shock.

Thanks everyone for your thought and opinions.

Same as the C.E. C2735

Even though there not a true double adj shock (Three way) I when and ordered front and rear shock.

Thanks everyone for your thought and opinions.

Again you're making my point even more...

a nice cheap welder on a nice inexpensive easy project like this sounds like a great starting point making easy brackets and learning how the puddle moves. then when you get some nice welding equipment you'll be super pro.

I just bought my first grinder or death wheel the pros cal then

Tried to cut my spring perches off with a little air die grinder.........after a hour of that i went and bought a cheap grinder from walmart. On sale for 22 dollars. them perches came off in no time and that flapper wheel attachment clean the rust off so that the back brace can be welded with ease also.

j par

Well-Known Member

You could have got it at Harbor Freight for $11 LOL great job love it finally you get to enjoy your hobby instead of paying somebody else to enjoy it for you..I just bought my first grinder or death wheel the pros cal then

Tried to cut my spring perches off with a little air die grinder.........after a hour of that i went and bought a cheap grinder from walmart. On sale for 22 dollars. them perches came off in no time and that flapper wheel attachment clean the rust off so that the back brace can be welded with ease also.

I forgot along with your welder you want to get a little four and a half inch grinder with a grinding wheel some cutting wheels and some flap Wheels. Lots of eye and ear protection and your set.

.

Looks like your fuel line came off the barb on the fuel pump.

-