Hey Guys, More naivety,

So I got some H116cp to go in this 360 I'm trying to build. I took it all to the local guy for balancing.

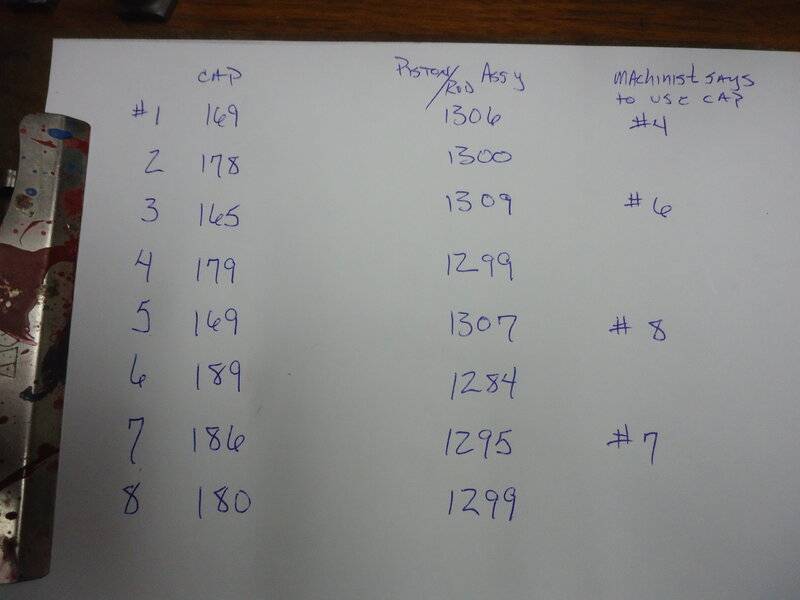

Tonight I was going to start ringing up the pistons. As I was pulling the parts out, I noticed some huge differences in the rod caps so I pulled out the ol' kitchen scale and started weighing things. I weighed everything three times.

I thought everything should be within a gram or so. This is shocking! Somebody please tell me this is how it's supposed to be. I won't believe you, but try. Note how the machinist says I need

to switch some of the caps to different piston/rod assy's, but only four, what about the other four? None of the weights make sense to me. WTF?

to switch some of the caps to different piston/rod assy's, but only four, what about the other four? None of the weights make sense to me. WTF?

If I assemble it with the correct caps in place the weight is 8 grams difference from low to hi. With the difference in material missing from the rod caps, how can the big end of all the rods weigh close to the same? Visibly 20 grams between 5 & 6. What does that do for the reciprocating balance? This doesn't look right to me from any angle. Help!

*That's supposed to be #1 cap on #7 assy.

So I got some H116cp to go in this 360 I'm trying to build. I took it all to the local guy for balancing.

Tonight I was going to start ringing up the pistons. As I was pulling the parts out, I noticed some huge differences in the rod caps so I pulled out the ol' kitchen scale and started weighing things. I weighed everything three times.

I thought everything should be within a gram or so. This is shocking! Somebody please tell me this is how it's supposed to be. I won't believe you, but try. Note how the machinist says I need

If I assemble it with the correct caps in place the weight is 8 grams difference from low to hi. With the difference in material missing from the rod caps, how can the big end of all the rods weigh close to the same? Visibly 20 grams between 5 & 6. What does that do for the reciprocating balance? This doesn't look right to me from any angle. Help!

*That's supposed to be #1 cap on #7 assy.