@dukeboy_318 The rhythm of your exhaust note is given by the LSA of the cam. The sound at the tailpipe end is mostly due to the muffler though header and exhaust pipe diameter play a small part.

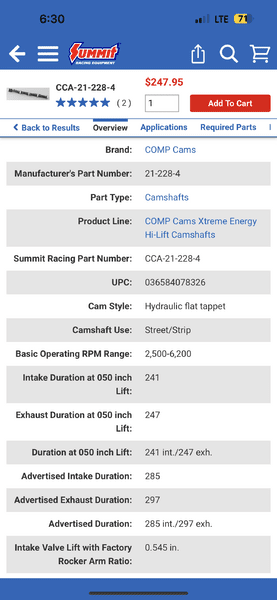

The smaller the number on the LSA will normally lead to an idle that has a chopping sound. More directly related is the amount of overlap. More overlap, the rougher the idle.

Since vacuum isn’t a concern, a cam with a LSA of 106. The amount of overlap should be somewhere between 70 - 90 degrees. The more overlap, if you can find that information, will lead to 2 things, a rougher idle and a higher rpm band where peak power is made.

If you like where your current or past cam performs AND you want a slight rise in high end rpm power, increase the overlap. If your 440 intake valve is smaller than 2.19, increase the LSA by 2*’s max.

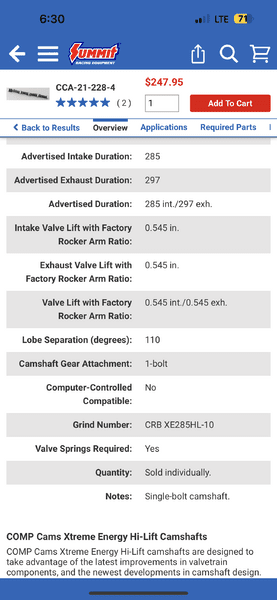

The difference between a hydraulic and a roller depends on the build. Your build is mild with the 10-1 ratio and cylinder head choice. I don’t see a big gain at all as also mentioned above, 17 hp is not a lot.

The choice of cam style is purely your choice. Build it once and don’t stray from the plan. It’ll only cost you more money in 90% of the time.

I have no experience with big block heads. You’ll have to wait for the been there and done that crew to show up. BUT! I can tell you about my small block head adventures. Most pushrod holes will accept a larger pushrod without much ram fair if any at all. However, a switch from a hydraulic or SFT cam to a roller or any style will require a shorter pushrod. The PROBLEM is the taller lifter creating an aggravated angle of the pushrod that will collide with the cylinder head in the pushrod tube. While the rod is not hard even with a tiny dremel die grinder, a real die grinder should be used.

You can easily run a stock diameter P-rod at a thicker wall & a stock diameter. I’m not sure if a larger 3/8 diameter P-rod will work OOTB with a HFT/SFT cam & the Edelbrock heads.