nm9stheham

Well-Known Member

You did a good test to isolate the misfiring cylinders. To check the 2 plugs either:

1) Swap out 2 other plugs in 2 of the working cylinders to 4 and 5 and see if the problems stays in 4 and 5 or moves to the other 2 cylinders.

2) Or, use the resistance setting of a voltmeter if you have one and check the resistance through the plugs and from the plug cap to the metla body. There should be very high resistance form cap to metal body, and no more than around 3000 or 4000 ohms (3k or 4k ohms) through the plug form the connection 'knob' to the firing tip.

You can do either of the same tests to check the wires to 4 and 5. Through resistance will vary from wire type to wire type. It should be less than 5 k ohm for a new resistance wire. Make sure the wires on the distributor are arranged around the distributor ca; if it is up near 10 k, it is time to replace. You can compare meter readings for all 6 wires.

Make sure the wires area all connected to the distributor top in the proper firing order, just in case you swapped 4 and 5 by mistake.

Let us know what you find. Isn't the shock fun?? Too hard on my old joints anymore! Pulling the wires at the distributor end lowers the chance to get zapped, BTW.

If it is bad plugs, then yes, replace then all. Too inexpensive to not do so.

If the plugs and wires are good for cyliinders 4 and 5, then it is time to see if the valves are working right, and then check compression on the cylinders.

What year is your car? The distributor advance vacuum hose for the older cars should be connnected to a port at the base of the carb below the throttle plate, not to a port up on the side of the carb body. But the later ones will be connected differently and the vaccum to the distributor advance may go through a temp controlled valve and another valve. We need to know the car's year and the situation with the emissions controls being intact. The vaccum situation is likely much less important than why cylinders 4 and 5 are not firing at this time.

BTW, how old is the gas? Is it old mixed with new? (And it hleps to get answers to all questions; there are reasons to ask them.)

1) Swap out 2 other plugs in 2 of the working cylinders to 4 and 5 and see if the problems stays in 4 and 5 or moves to the other 2 cylinders.

2) Or, use the resistance setting of a voltmeter if you have one and check the resistance through the plugs and from the plug cap to the metla body. There should be very high resistance form cap to metal body, and no more than around 3000 or 4000 ohms (3k or 4k ohms) through the plug form the connection 'knob' to the firing tip.

You can do either of the same tests to check the wires to 4 and 5. Through resistance will vary from wire type to wire type. It should be less than 5 k ohm for a new resistance wire. Make sure the wires on the distributor are arranged around the distributor ca; if it is up near 10 k, it is time to replace. You can compare meter readings for all 6 wires.

Make sure the wires area all connected to the distributor top in the proper firing order, just in case you swapped 4 and 5 by mistake.

Let us know what you find. Isn't the shock fun?? Too hard on my old joints anymore! Pulling the wires at the distributor end lowers the chance to get zapped, BTW.

If it is bad plugs, then yes, replace then all. Too inexpensive to not do so.

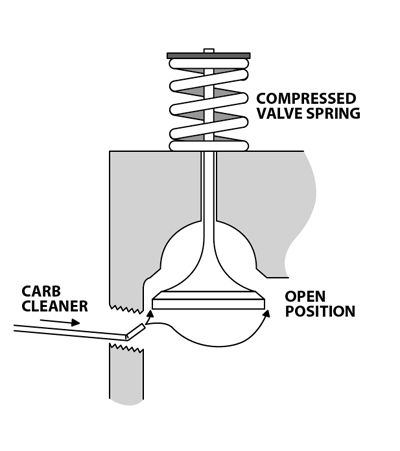

If the plugs and wires are good for cyliinders 4 and 5, then it is time to see if the valves are working right, and then check compression on the cylinders.

What year is your car? The distributor advance vacuum hose for the older cars should be connnected to a port at the base of the carb below the throttle plate, not to a port up on the side of the carb body. But the later ones will be connected differently and the vaccum to the distributor advance may go through a temp controlled valve and another valve. We need to know the car's year and the situation with the emissions controls being intact. The vaccum situation is likely much less important than why cylinders 4 and 5 are not firing at this time.

BTW, how old is the gas? Is it old mixed with new? (And it hleps to get answers to all questions; there are reasons to ask them.)