rod7515

Well-Known Member

Im working on a 360 stroked to a 408 and bored .030. It has a Comp cam that is 575 on both intake and exhaust, compression is at 10.5 - 1.

Has steel J-heads with oversized valves.

Running an edelbrock victor intake with a 750 holley double pump. TTI headers.

Has a mechanical auto gauge, sending prong is in the intake just behind the thermostat housing

New Champion 3 core radiator, 2 electric fans pulling 2300 CFM each. Fans come on at about 160*

Coolant is at +5* and I have 1.5 bottles of water wetter installed after the first drive listed below.

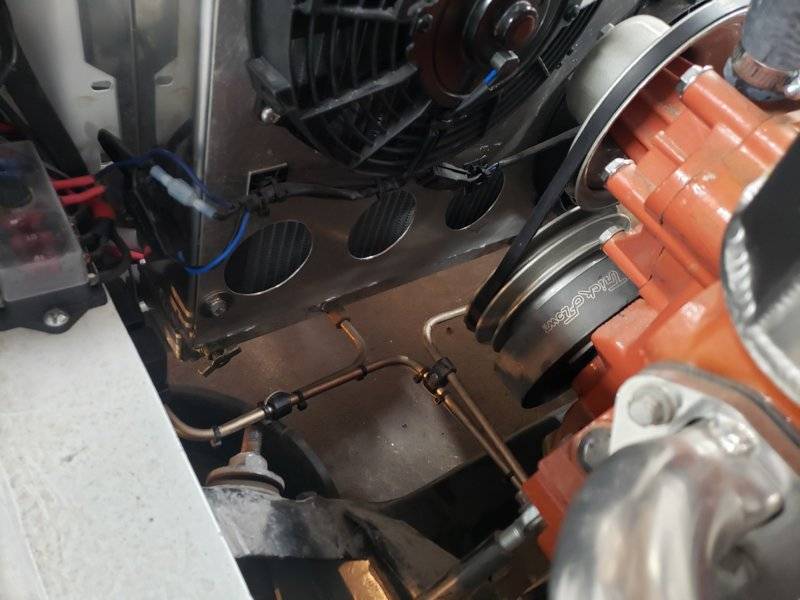

Here are pics

The pulleys seem to be the same size or very close. Looks to be about 6.25".

The pulleys seem to be the same size or very close. Looks to be about 6.25".

The water pump is a napa high flow with 8 veins.

Timing is at 14* base and 32* at 3K

The holes that appear on the shroud I just did and have not driven on the road since this was done.

Im overheating, Ive had this on the road for about 12 miles. it was 2 different nights and both drives were 3 miles and a stop of about 15 minutes then the 3 mile drive home. Temp both nights was around 60* in the evening. First drive was with a 180* thermostat. When i got to the stop at the 3 mile mark it was running at 195* on the gauge. After about 15 minutes I started up and drove the 3 miles home. By the time I arrived and put in the garage the temp went to 225* where I turned it off.

Next night I installed a 160* thermostat and drove the same trip. Temp went to 195* and again by the time I got home I was at 225*.

Next night I installed a 195* but didnt drive it. I just left it run in front of garage. It took about 25 minutes or so but it went to 225*.

I have not left the temp go abouve the 225* as thats were I have turned it off before it can go higher.

So tonight I remove the thermostat and took some numbers as the car sat and ran mostly at idle which is about 1100 RPMs.

The Intake sensor, upper hose and head temp are from an infra red tester.

Here shows the head area I am measuring, and the temp unit in the intake.

I started the car at 9:27

Gauge Temp Intake Sensor Upper Hose Head

9:30 125*

9:33 150*

9:36 165* 145* 141* 158*

9:39 170* 155* 150* 165*

9:42 190* 165* 165* 180*

9:45 195* 175* 170* 195*

9:48 205* 185* 178* 210*

9:51 215* 195* 190* 210*

9:54 220*

Turned the car off at this point. The radiator at this point is only at 110* on top of the tank at the inlet, the fins at upper hose in the radiator are at 190*, the lower tank at the lower passenger side is at 115* while the lower fins near the lower hose passenger side are at 165*.

Heres the part that bothers me. I ran a test with a block tester that uses the blue fluid and pulls the coolant vapors and will turn green/yellow if carbon monoxide gases are present in the coolant and mine tests positive. I Had the heads magnafluxed before the build as well as the block. No issues. I struggle to believe a head gasket issue but I guess anything is possible.

During the 2 drives or even the last 2 times just idling I have not lost any fluid while driving, the car has not spit any coolant out, and the radiator runs cooler when on the road even tho the gauge goes to 225* the radiator has always been around the 150-160* temp. Also there is no build up of pressure in the system as the hose can be compressed.

Ive also done the old school test where I removed the water pump belt, taken the thermostat housing off and filled intake to top. Start the car and I get no bubbles at all.

My next test will be a stewart high flow 180* thermostat. also a new gauge although I think this gauge is reading close compared to infra tester

What are your thoughts? Did I leave out any info that would help figure this out?

Thanks Rod

Has steel J-heads with oversized valves.

Running an edelbrock victor intake with a 750 holley double pump. TTI headers.

Has a mechanical auto gauge, sending prong is in the intake just behind the thermostat housing

New Champion 3 core radiator, 2 electric fans pulling 2300 CFM each. Fans come on at about 160*

Coolant is at +5* and I have 1.5 bottles of water wetter installed after the first drive listed below.

Here are pics

The water pump is a napa high flow with 8 veins.

Timing is at 14* base and 32* at 3K

The holes that appear on the shroud I just did and have not driven on the road since this was done.

Im overheating, Ive had this on the road for about 12 miles. it was 2 different nights and both drives were 3 miles and a stop of about 15 minutes then the 3 mile drive home. Temp both nights was around 60* in the evening. First drive was with a 180* thermostat. When i got to the stop at the 3 mile mark it was running at 195* on the gauge. After about 15 minutes I started up and drove the 3 miles home. By the time I arrived and put in the garage the temp went to 225* where I turned it off.

Next night I installed a 160* thermostat and drove the same trip. Temp went to 195* and again by the time I got home I was at 225*.

Next night I installed a 195* but didnt drive it. I just left it run in front of garage. It took about 25 minutes or so but it went to 225*.

I have not left the temp go abouve the 225* as thats were I have turned it off before it can go higher.

So tonight I remove the thermostat and took some numbers as the car sat and ran mostly at idle which is about 1100 RPMs.

The Intake sensor, upper hose and head temp are from an infra red tester.

Here shows the head area I am measuring, and the temp unit in the intake.

I started the car at 9:27

Gauge Temp Intake Sensor Upper Hose Head

9:30 125*

9:33 150*

9:36 165* 145* 141* 158*

9:39 170* 155* 150* 165*

9:42 190* 165* 165* 180*

9:45 195* 175* 170* 195*

9:48 205* 185* 178* 210*

9:51 215* 195* 190* 210*

9:54 220*

Turned the car off at this point. The radiator at this point is only at 110* on top of the tank at the inlet, the fins at upper hose in the radiator are at 190*, the lower tank at the lower passenger side is at 115* while the lower fins near the lower hose passenger side are at 165*.

Heres the part that bothers me. I ran a test with a block tester that uses the blue fluid and pulls the coolant vapors and will turn green/yellow if carbon monoxide gases are present in the coolant and mine tests positive. I Had the heads magnafluxed before the build as well as the block. No issues. I struggle to believe a head gasket issue but I guess anything is possible.

During the 2 drives or even the last 2 times just idling I have not lost any fluid while driving, the car has not spit any coolant out, and the radiator runs cooler when on the road even tho the gauge goes to 225* the radiator has always been around the 150-160* temp. Also there is no build up of pressure in the system as the hose can be compressed.

Ive also done the old school test where I removed the water pump belt, taken the thermostat housing off and filled intake to top. Start the car and I get no bubbles at all.

My next test will be a stewart high flow 180* thermostat. also a new gauge although I think this gauge is reading close compared to infra tester

What are your thoughts? Did I leave out any info that would help figure this out?

Thanks Rod