Electronic Ign. Control Unit (ECU) Heat condition

It would be really helpful if you're OK with combining your electrical issues into this thread.

ref: Car won't even crank...

While both are '74s, yours is modified.

Kit suggested taking posting photos. That would be really helpful. Not just here but also with the other connections such as the ballast resistor and ECU.

With a PC, take a digital photo and drop and drag onto post. It can be done with cell phones too. Someone else can help with that if needed.

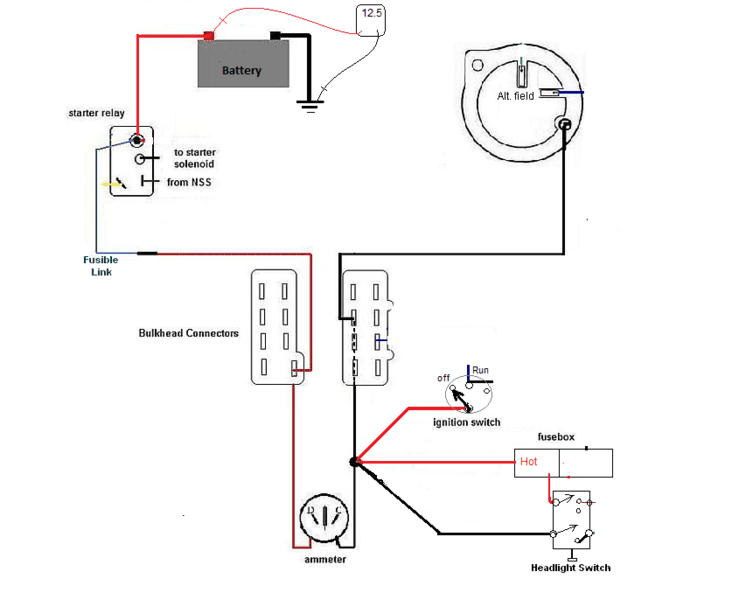

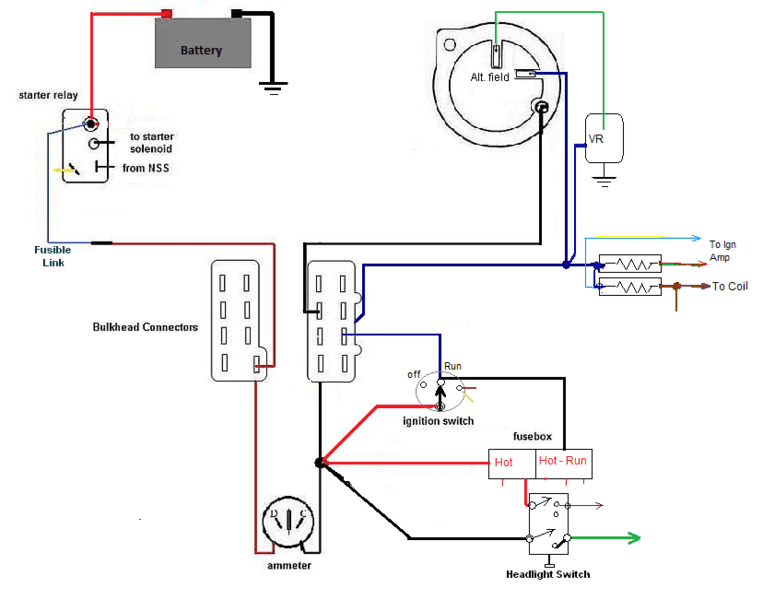

Here's one from way back showing a fairly stock '74.

Not Getting 12 Volts at Coil

If the battery is at 12.5 V, then everything in the system shown below is at 12.5 Volts

But in our cars there are two power sources tied together.

So when the alternator is running it supplies power at the regulated set point, around 14 Volts. (As long as it can meet the demand; otherwise voltage drops)

All of the wires shown above should be or close to the alternator output voltage.

Picture it like pressure in your house plumbing with all of the taps shut. Or like pressure from an air compressor. Attach a system with two or three hoses to the compressor. Pressure in the hoses is the same as at the compressor.

Here's a catch: When the switch is in run, the ignition and alternator are turned on. In other words they draw power when the key is in run. This is important to know. Any time the power is flowing out of the battery, its voltage will drop. The most extreme case is when the car is started, battery voltage may go down to 11, 10 or even 9 volts depending on the starter's current draw and battery condition.

Fully twisted clockwise connects ignition switch feed to the ignition 2 (start) wire(s )and the starter relay wire.

Placement in trunk is generally done to shift weight for racing.

Disadvantage is a the long runs of wire and at least for non-glasmat batteries, venting them out of the trunk.

It would be really helpful if you're OK with combining your electrical issues into this thread.

ref: Car won't even crank...

While both are '74s, yours is modified.

If this was voltage under load, then we could be more confident about the condition of charge.

With everything off, 12.4 Volts is probably OK. Not outstanding, and not bad.

Kit suggested taking posting photos. That would be really helpful. Not just here but also with the other connections such as the ballast resistor and ECU.

With a PC, take a digital photo and drop and drag onto post. It can be done with cell phones too. Someone else can help with that if needed.

Here's one from way back showing a fairly stock '74.

Not Getting 12 Volts at Coil

I'll answer this below where you correct the description.

The system voltage should be the same in every supply wire that is connected to a power source.

If the battery is at 12.5 V, then everything in the system shown below is at 12.5 Volts

But in our cars there are two power sources tied together.

So when the alternator is running it supplies power at the regulated set point, around 14 Volts. (As long as it can meet the demand; otherwise voltage drops)

All of the wires shown above should be or close to the alternator output voltage.

Picture it like pressure in your house plumbing with all of the taps shut. Or like pressure from an air compressor. Attach a system with two or three hoses to the compressor. Pressure in the hoses is the same as at the compressor.

When the key is in RUN, power is made available to ignition and accessory feeds.

Here's a catch: When the switch is in run, the ignition and alternator are turned on. In other words they draw power when the key is in run. This is important to know. Any time the power is flowing out of the battery, its voltage will drop. The most extreme case is when the car is started, battery voltage may go down to 11, 10 or even 9 volts depending on the starter's current draw and battery condition.

Fully twisted clockwise connects ignition switch feed to the ignition 2 (start) wire(s )and the starter relay wire.

If this is the start wire to the relay, it should have no voltage except when the key is in Start position. In start, it should have the same voltage as the battery. In other words roughly 12 Volts above ground but will depend on the starter load and batttery condition. If you measure from battery positive to the connection (back probe the connector while connected), the voltage difference should be very small. Certainly under a volt; preferable a 1/2 Volt or less IMO.

If the battery tray is still in place, its an easy thing to do.

Placement in trunk is generally done to shift weight for racing.

Disadvantage is a the long runs of wire and at least for non-glasmat batteries, venting them out of the trunk.