motorpirate

serial mopar owner

So we finally have Danys trans together and the shift kit/valve body mods are next.

It's an A998 from an 03 B van.

Electronic lockup.

We have ordered a 10" Turbo Action non lockup converter.

26 spline (lockup input shaft) with drive flats not slots.

The people at Turbo Action could not have been nicer!!!

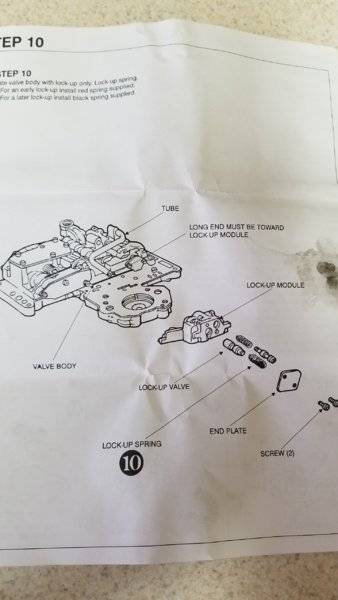

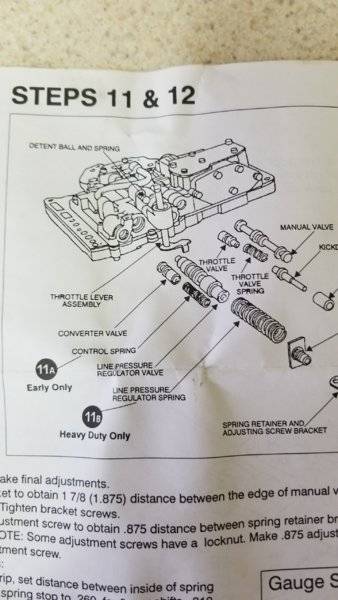

Our question is, what do we need to do about the lockup features in the valve body, if anything?

It is electronic lockup with an electric solenoid on the valve body.

Is not applying 12 volts to it enough to deactivate it?

Or do I need to block one or both of the converter related valves?

I see 2 potential spots, block in place of the lockup spring?

Or the converter valve spring?

Both?

Neither?

And, what would happen if it tried to "lock up" on a non lockup converter?

And, thanks in advance guys.

We would not be within sight of her making a 13 second pass in what was a 17 second car without everyone's support on this site!!

It's an A998 from an 03 B van.

Electronic lockup.

We have ordered a 10" Turbo Action non lockup converter.

26 spline (lockup input shaft) with drive flats not slots.

The people at Turbo Action could not have been nicer!!!

Our question is, what do we need to do about the lockup features in the valve body, if anything?

It is electronic lockup with an electric solenoid on the valve body.

Is not applying 12 volts to it enough to deactivate it?

Or do I need to block one or both of the converter related valves?

I see 2 potential spots, block in place of the lockup spring?

Or the converter valve spring?

Both?

Neither?

And, what would happen if it tried to "lock up" on a non lockup converter?

And, thanks in advance guys.

We would not be within sight of her making a 13 second pass in what was a 17 second car without everyone's support on this site!!