You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

W2 intake manifolds pics

- Thread starter rumblefish360

- Start date

-

MiradaMegaCab

Well-Known Member

Evil, does Bill Laney of WaxWedge Performance still cast those manifolds?

View attachment 1715159849

Evil, does Bill Laney of WaxWedge Performance still cast those manifolds?

Not sure if Bill is still doing them but i did speak to his son anthony a while ago and he was able to cast them,when i was considering using W5 heads over the W2.

MiradaMegaCab

Well-Known Member

Yeah, Bill was casting Mopar blower manifolds for use with B&M blowers and 6-71 blowers in standard and W2 heads.

Just a general FYI...... he made a really nice, hi quality manifold!!

Evil, keep us posted with any info!!

Just a general FYI...... he made a really nice, hi quality manifold!!

Evil, keep us posted with any info!!

MoPar W2 - M1 - TR

Tryin!!!!!!!

Tryin!!!!

Tryin!!!!

turbodart68

Well-Known Member

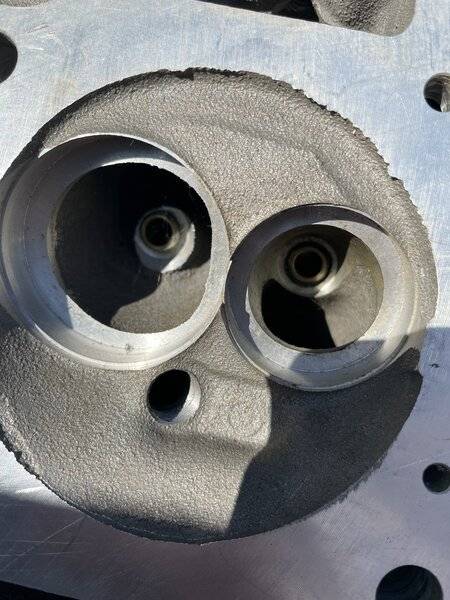

Did someone mention Batten W2s? Here are mine with a Holley Pro Dominator Tunnel Ram converted to EFI with a Hogans top.

NoCar340

The Original Partstitute

I'm once again reviving this because I can't believe none of you cool dudes had one of these bad motherforklifters lying around.

The ultimate sleeper intake, an NOS P5249194, for your perusal.

Production-line 360 (and 318 cop) casting number:

It certainly doesn't look like anything special...

As you look closer, though, the details become evident. I've never seen an OE manifold machined like this for the center bolts.

Strange things are afoot at the Circle K regarding the EGR boss, too:

None of the accessory bosses nor the heater/vacuum ports have been drilled or tapped, including the coil mounts:

The boss atop the #4 port is required to install the OE '78-up axial AC compressor using factory bracketry once it's also drilled & tapped.

Port-matching was left to the end user. They used the stock LA cores for the runners.

Where they didn't use the LA core, and I wish they had, was for the heat crossover. That big pad? It's solid cast iron, as is any spot where there would've been cores for choke heat. This manifold weighs about 65lb according to my bathroom scale. It would require a lot of milling, drilling, and grinding to approximate the weight of its production-line 360 counterpart.

The weight is why I've never used it. When I bought it, I was loving the sleeper aspect. Picture it: A '78-'80 F-body or ex-cop M-body lightened as much as possible, with junkyard truck valve covers (all chipped up, big part number decal, the works) atop a pair of early unmarked W2s, with the AC compressor still in place, worked-but-dirty TQ, etc. To all the world it's the original 318 other than the headers. Such wonderful fun... Unfortunately,the armchair physicist in me just can't bolt something this heavy on a performance engine.

The ultimate sleeper intake, an NOS P5249194, for your perusal.

Production-line 360 (and 318 cop) casting number:

It certainly doesn't look like anything special...

As you look closer, though, the details become evident. I've never seen an OE manifold machined like this for the center bolts.

Strange things are afoot at the Circle K regarding the EGR boss, too:

None of the accessory bosses nor the heater/vacuum ports have been drilled or tapped, including the coil mounts:

The boss atop the #4 port is required to install the OE '78-up axial AC compressor using factory bracketry once it's also drilled & tapped.

Port-matching was left to the end user. They used the stock LA cores for the runners.

Where they didn't use the LA core, and I wish they had, was for the heat crossover. That big pad? It's solid cast iron, as is any spot where there would've been cores for choke heat. This manifold weighs about 65lb according to my bathroom scale. It would require a lot of milling, drilling, and grinding to approximate the weight of its production-line 360 counterpart.

The weight is why I've never used it. When I bought it, I was loving the sleeper aspect. Picture it: A '78-'80 F-body or ex-cop M-body lightened as much as possible, with junkyard truck valve covers (all chipped up, big part number decal, the works) atop a pair of early unmarked W2s, with the AC compressor still in place, worked-but-dirty TQ, etc. To all the world it's the original 318 other than the headers. Such wonderful fun... Unfortunately,the armchair physicist in me just can't bolt something this heavy on a performance engine.

Last edited:

I’d have to, just to see and feel how it works, it’s a must in my head. These are stupid crazy rare and hard to find. I’m sure you’ll find some used ones at a race track going round in circles. Where ever the rules limited intakes to cast iron.

NoCar340

The Original Partstitute

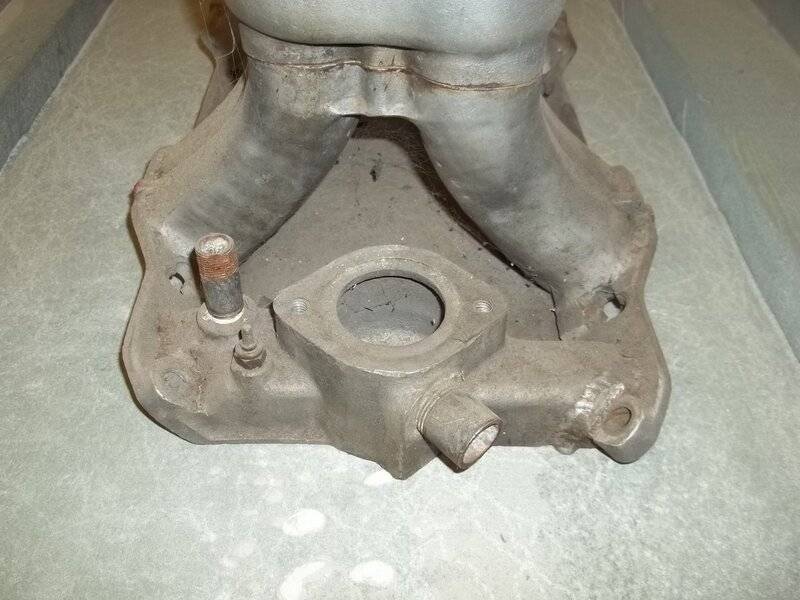

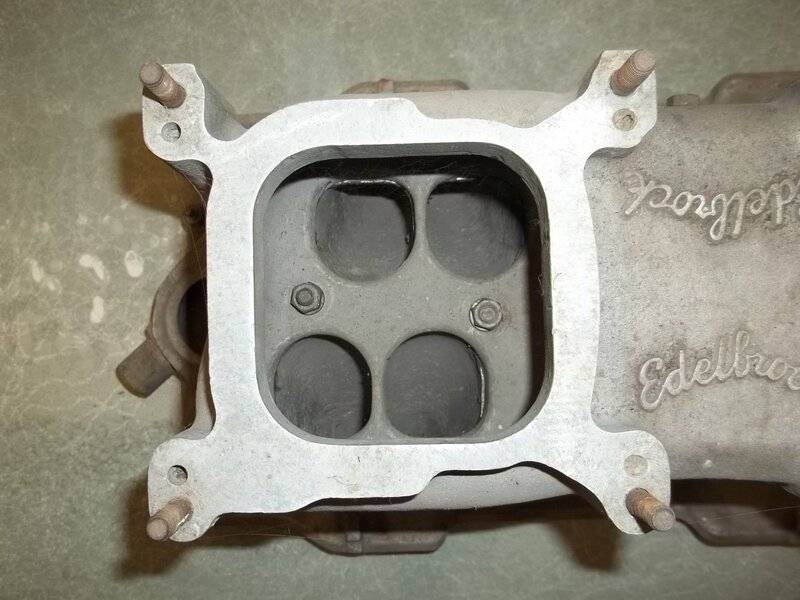

Modified and repaired Edelbrock W2 tunnel ram. Due to modification, there are no identifying marks other than the brand name. Apparently some dolt tried to use this on standard LA heads, hence the hacked mounting holes, but the bolt countersinking and ports show it is a native W2 manifold.

The bottom of the casting was cut out and a thin aluminum plate welded in, I assume to lower the weight.

A view up the stinkholes. Pro tip: Cobwebs increase port velocity for gooder low-end grunt.

Repair welds visible up front...

...and signs of wholesale butchery to the casting out back.

Apparently the plenum's on backward, according to this stamping. Plenum volume is not in short supply here.

What the carb base sees:

Finally, an overall aerial shot:

The bottom of the casting was cut out and a thin aluminum plate welded in, I assume to lower the weight.

A view up the stinkholes. Pro tip: Cobwebs increase port velocity for gooder low-end grunt.

Repair welds visible up front...

...and signs of wholesale butchery to the casting out back.

Apparently the plenum's on backward, according to this stamping. Plenum volume is not in short supply here.

What the carb base sees:

Finally, an overall aerial shot:

NoCar340

The Original Partstitute

To my knowledge, it was never pictured in the DC/MP catalogs, so part of the reason I got it was just to see what the factory had dreamed up for a cast W2 intake. The sleeper bit certainly didn't hurt--I love a good sleeper--and it was cheap, too. It's still the only one I've seen, and the factory paperwork is still with it even though the box was not.I’d have to, just to see and feel how it works, it’s a must in my head. These are stupid crazy rare and hard to find. I’m sure you’ll find some used ones at a race track going round in circles. Where ever the rules limited intakes to cast iron.

I have a bunch of W2 intakes; these were the only two nobody'd covered. There are also three Victors, two Strip Dominators, a Street Dominator, the water-heated M1 Single plane, and the M1 dual plane. The tunnel ram (oy!), one of the Strip-Ds, and two of the Victors are used. The rest are NOS.

I have seen pictures of the cast iron intake you have above for the W2 before but it was a little different. That TR looks just like the LA tunnel ram I had for a short time.

turbodart68

Well-Known Member

Thats quite the collection of W2 history. I know that Chrysler was eyeballing putting the W2 on the little red express trucks in 78. This intake you have shown is the first real piece of evidence that supports that theory. Thanks for sharing!To my knowledge, it was never pictured in the DC/MP catalogs, so part of the reason I got it was just to see what the factory had dreamed up for a cast W2 intake. The sleeper bit certainly didn't hurt--I love a good sleeper--and it was cheap, too. It's still the only one I've seen, and the factory paperwork is still with it even though the box was not.

I have a bunch of W2 intakes; these were the only two nobody'd covered. There are also three Victors, two Strip Dominators, a Street Dominator, the water-heated M1 Single plane, and the M1 dual plane. The tunnel ram (oy!), one of the Strip-Ds, and two of the Victors are used. The rest are NOS.

That’s actually a little off base I think. While the engineers only tested the W2 on the LRT engine set up in the dyno rooms, the iron intake for the W2 came out years later. I don’t think it supports that theory.

NoCar340

The Original Partstitute

I have a set of semi-machined prototype W2 heads that were being advertised as LRT development heads when I bought them. I believe they were shown as such because they still have factory-style heat crossover passages, while W2s never did. Bill Richardson, who worked heavily in the W2 and SCCA programs, identified them as what he called "W1" heads. He said they were originally intended for SCCA cars, even though Chrysler was no longer directly involved. He was also extremely curious as to how I got my hands on them, as "we cast less than 25 sets of those and I'm sure I knew where every single casting went."

Michael @ B3 Racing was a great help in getting them identified. He recommended I leave them alone (as opposed to finishing the machine work and using them) due to their potential historical value. They're currently sitting on a pallet in my basement, not far from where the iron W2 intake normally sits. Prior to learning what those heads were, I had considered building a "what if" LRT W2 engine.

The cast-iron intake was intended for circle-burners with rules requiring an iron "production type" manifold. The W2 spec for the LRT had called for an aluminum Edelbrock intake and a Holley carb, if memory serves.

Michael @ B3 Racing was a great help in getting them identified. He recommended I leave them alone (as opposed to finishing the machine work and using them) due to their potential historical value. They're currently sitting on a pallet in my basement, not far from where the iron W2 intake normally sits. Prior to learning what those heads were, I had considered building a "what if" LRT W2 engine.

The cast-iron intake was intended for circle-burners with rules requiring an iron "production type" manifold. The W2 spec for the LRT had called for an aluminum Edelbrock intake and a Holley carb, if memory serves.

NoCar340

The Original Partstitute

It only bolts to W2 heads. W2 intake bolts are spaced differently. If the factory LA bolt pattern was used, the intake bolts would protrude into the area where the intake pushrods live with the offset rockers. T/A heads had a lot less rocker offset, so the production pattern didn't present a problem.I'm curious what designates the cast iron manifold as w2 if it uses standard la for runners? That being said, all cast iron stuff excites me. I'm interested in all odd ball small block stuff.

Wider intake bolt spacing. Exempt the 4 at the extreme ends of the intake.I'm curious what designates the cast iron manifold as w2 if it uses standard la for runners? That being said, all cast iron stuff excites me. I'm interested in all odd ball small block stuff.

Oval intake ports.

Those are works of art, Im jealous!One in each flavor, 4150 and 4500.

View attachment 1716078745

turbodart68

Well-Known Member

If we are doing show and tell here is my W2 pro dominator modified for fuel injection and a sheetmetal top for turbo.

-

Get busy !

Get busy !