Cold day after a high desert snow, say inside and do some detail work. 1/16” setters tape is perfect for these vent windows.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1966/'69 A100 Twins Build

- Thread starter Jim Kueneman

- Start date

-

Booty from the salvage yard adventure Friday

Almost perfect door panels, flip forward seat bracket set, correct V8 pulleys, full set of auto V8 throttle and kickdown rods with bell cranks, Dodge horn center cap and a stash of special door panel screws

Almost perfect door panels, flip forward seat bracket set, correct V8 pulleys, full set of auto V8 throttle and kickdown rods with bell cranks, Dodge horn center cap and a stash of special door panel screws

The only good thing about drilling out welds is the last one

Wow, hammer and dolly on 14 gauge needs a torch here and there The dent and 1” bow in the center of the tailgate is fixed. Taking it in to get it blasted with a serious blaster then fab a simple panel and the last metal work on this thing is DONE.

Wow, hammer and dolly on 14 gauge needs a torch here and there The dent and 1” bow in the center of the tailgate is fixed. Taking it in to get it blasted with a serious blaster then fab a simple panel and the last metal work on this thing is DONE.

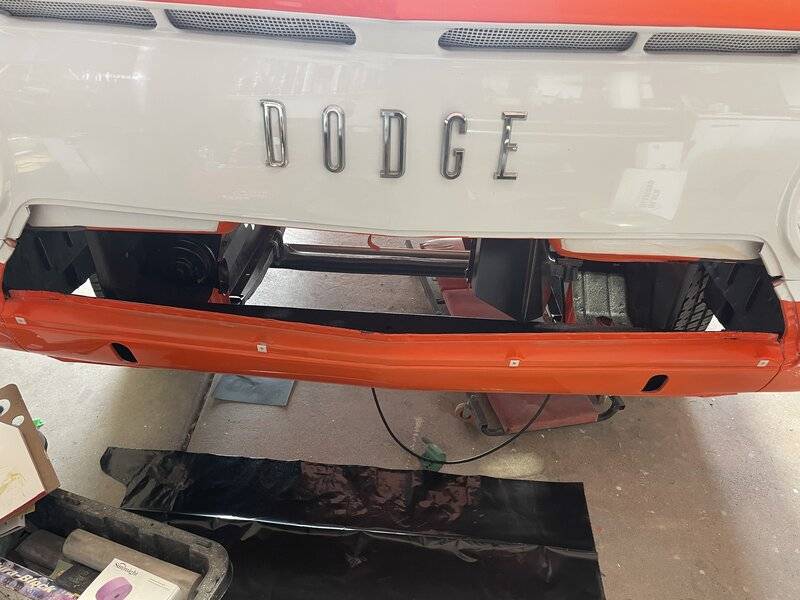

It’s starting to warm up and I’m getting re-energized on getting this truck done. First step is to fix a couple of of the screw ups that frustrated me and encourage me to put it away for a month. Orange overspray everywhere.

Windshield opening fixed (always see how far out (or how far it does not come out) the window seal goes before painting and making assumptions), white cleared in the cab. Just need to do the same to the white on the backside of the front “fenders” and front edge of the doors and the cab will be ready to finish cutting and buffing then assembly can start.

Richard Sweet

Well-Known Member

Jim,

I sure hope you're not going to use the tail gate chains on it. They will ding up your beautiful paint job.

I sure hope you're not going to use the tail gate chains on it. They will ding up your beautiful paint job.

Last thing to fix once it warms up a bit more and I can finish cutting and buffing. Then final assembly can start!

Most would call me an idiot for spending 3 days getting the door jambs to look this good but it is the details that take a restoration over the top. Worth it in my opinion. I’m DONE painting on the body. Time to finish the cut and buff for the money finish.

Sometimes OCD works in your favor.

Wow!! Jim that’s so impressive.

Great work….. and attention to detail makes a huge difference!!

Great work….. and attention to detail makes a huge difference!!

All sanded and a few chips from clumsiness fixed. Tomorrow is buffing time.

Anybody that’s been following knows I can’t leave well enough alone, if there’s sunshine there’s work time. This is one pass with a wool pad and CSI polish after 1500 grit wet. Finish it up tomorrow.

Anybody that’s been following knows I can’t leave well enough alone, if there’s sunshine there’s work time. This is one pass with a wool pad and CSI polish after 1500 grit wet. Finish it up tomorrow.

Last edited:

Damn, I can hardly wait to see the old girl all dressed out.

Wow Jim! That looks fantastic.

What a great job!

What a great job!

Just need to hit the RH side with a foam pad and swirl remover and buff out below the tailgate. The rear bumper is hammered out ready for pickup and test fitting before chrome.

As usual Jim AMAZING!! I'm still trying to wetsand & buff the blemishes on mine. Great work. ENVY/ENVY ,ENVY.

great to hear from you Mac. I was thinking about you the other day

Only was going to work a few hours on the truck. Eight hours later….. door guts are blasted, painted, lubed and assembled. Only thing left is dig the glass and channel out and see what shape it’s in. I have several other pieces of glass if the originals are too bad.

The door handles and window cranks are at the chrome shop and the vent handles are too so they can be polished.

These are Tradesman doors with the holes for the lower trim. Need to get the material to make a vinyl door lower panel.

Love Herb’s interior paint. MOPAR specific interior color only.

Thanks @cudamark for keying the unobtainium door and key cylinders!

The door handles and window cranks are at the chrome shop and the vent handles are too so they can be polished.

These are Tradesman doors with the holes for the lower trim. Need to get the material to make a vinyl door lower panel.

Love Herb’s interior paint. MOPAR specific interior color only.

Thanks @cudamark for keying the unobtainium door and key cylinders!

Last edited:

340sFastback

Well-Known Member

Crazy high skills amazing how awesome that truck looks.

Another exciting day of media blasting. I hate to reuse front end components but since all you can get is the drag link from rare parts for $690 the original only had about 50,000 miles and is super tight so I cleaned it inside and out removed all the grease and will repack it with new dust seals. Pulled the wiper system apart, I’ll show why wiper switches and motors shorted out on these early Prestolite systems when I rewire it.

Also, cleaned up and located all the holes for the chrome. This is just leftovers I had for templates the real stuff still at the chrome plater.

Also, cleaned up and located all the holes for the chrome. This is just leftovers I had for templates the real stuff still at the chrome plater.

Bunch of tinkering, polishing and test fitting. Also painted the grill but it got hailed on before the clear set up and I missed a few dents. Needs a bit more work but new hardware worked. The headlight trim hardware not so much, another order to McMaster Carr coming. Also, the headlight adjusters are exactly like my 66 Valiant! So I have some ShapeWay parts I created to replace them! Order them too. Looks like I need a bit more blackout behind the grill.

The attention to detail to all the components , the finish work ... absolutely as close to perfect as one can get !

My hats of to you sir ... Take a bow

My hats of to you sir ... Take a bow

Picked up the blasted parts today. Inside of the tailgate is now rust free. Epoxy prime it tomorrow then fabricate the patch panel. The gate hinges were a nightmare but now new oversized pins and like new.

All the factory V8 parts are blasted ready for black epoxy.

The 1968 Dart arms rests fit perfectly.

The glass I have to too scratched for the quality of this build. Dropped off templates for a glass company to make me new everything.

Low spots in the grill fixed with glaze. I need to make the grill 2 tone as it was from the factory after looking at it all week.

All the factory V8 parts are blasted ready for black epoxy.

The 1968 Dart arms rests fit perfectly.

The glass I have to too scratched for the quality of this build. Dropped off templates for a glass company to make me new everything.

Low spots in the grill fixed with glaze. I need to make the grill 2 tone as it was from the factory after looking at it all week.

-