really nice work!!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1966/'69 A100 Twins Build

- Thread starter Jim Kueneman

- Start date

-

It has been a much longer and harder road than I anticipated but I can see the end zone.

abdywgn

dismantler

no sitting on the roof at the drive-in watching movies!

no sitting on the roof at the drive-in watching movies!

I won't even let you in the bed when it is done... ;)

Roof and cab back glazed and 2k’ed ready for blocking and epoxy primer tomorrow. The weather is continuing to hold for me.

JDMopar

Well-Known Member

Your 37 lb. turkey from SPI should probably arrive tomorrow.....just in time!

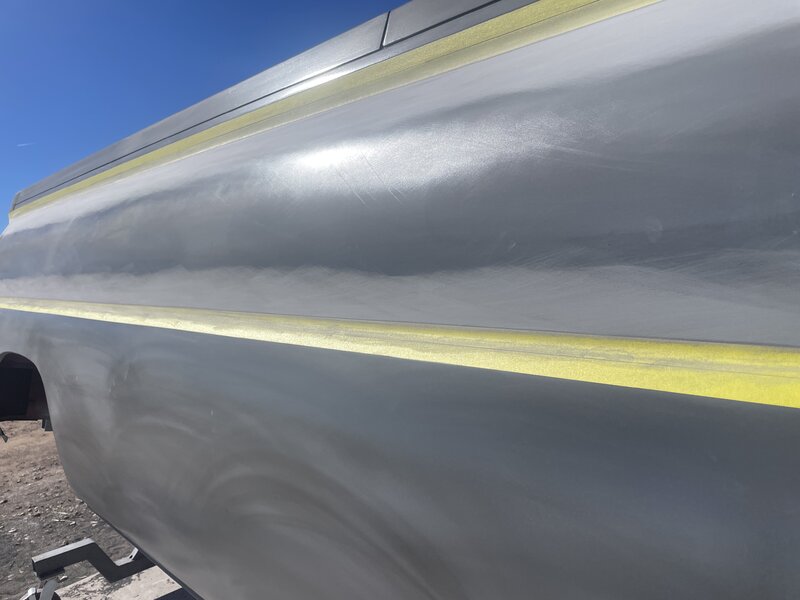

And Round 2, ding-ding-ding. She is as flat as I’m going to make it (and that is pretty dang flat). Two coats of SPI epoxy primer and a wet sand with 320 is next. I’m hoping I don’t find anymore low spots on the roof. I’m tired of sanding.

mygasser

Well-Known Member

that's got to be straighter and have better gaps than it had from the factory

neil.

neil.

that's got to be straighter and have better gaps than it had from the factory

neil.

Since it had a hundred spot welds in the exterior panels from the factory that is a safe bet!

A couple little flaws were revealed, nothing a dab of glaze won’t solve. Wet blocking with 320 next. Straightest and most rust free A100 on the planet? Has to be close.

Almost done blocking with 320. Just the LH inner bed and a bit of the floor to do. Two heavy coats of epoxy primer and a wet sand to get any orange peel and crap out and it is ready for paint. It is straight as an arrow.

JDMopar

Well-Known Member

You've been gitten it! Do you do all of your blocking on the epoxy, or do you use SPI 2K high build also?

You've been gitten it! Do you do all of your blocking on the epoxy, or do you use SPI 2K high build also?

There is some high build since this is so crooked.

JDMopar

Well-Known Member

Well....there went your SPI Christmas ham with all the fixins!

Got the 225 back from the machine shop. Time to slap on the Webers and install it. Some assembly may be required.

LMAO!!!

JDMopar

Well-Known Member

Dang....where'd you get that huge *** quarter?

Jeff Seighman

aka jeffnmo

Gives a new meaning to light weight!Got the 225 back from the machine shop. Time to slap on the Webers and install it. Some assembly may be required.

View attachment 1716171920

So this is where all the cuts, bruises, long days and frustration pay off. Shot the last two coats of Southern Polyurathane epoxy primer with my good gun very little texture to sand out with 400 and it’s ready for solid base. If it was going to be a metallic color, it would need to be 600. The next few days are going to be cool and stormy so I will get the interior sanded down and fixed up ready for final epoxy at a leasurly pace. I need the rest.

I have been trying to figure out how many coats of primer you have sprayed and I lost count weeks ago.

I have been trying to figure out how many coats of primer you have sprayed and I lost count weeks ago.

Me too! The penalty for doing it outside and in stages. After 4-5 days in the sun it is cured enough to not have a good chemical bond so you have to start fresh coat of epoxy. The beauty about this though it the epoxy is SUPER durable so it actually makes it even stronger and more durable. Remeber I have been doing it in sections too so yes I have sprayed epoxy on MANY days but in the same section there is:

Red Epoxy to lock down the metal for the first stage

Grey epoxy to do the filler work over

Filler Work and blocking

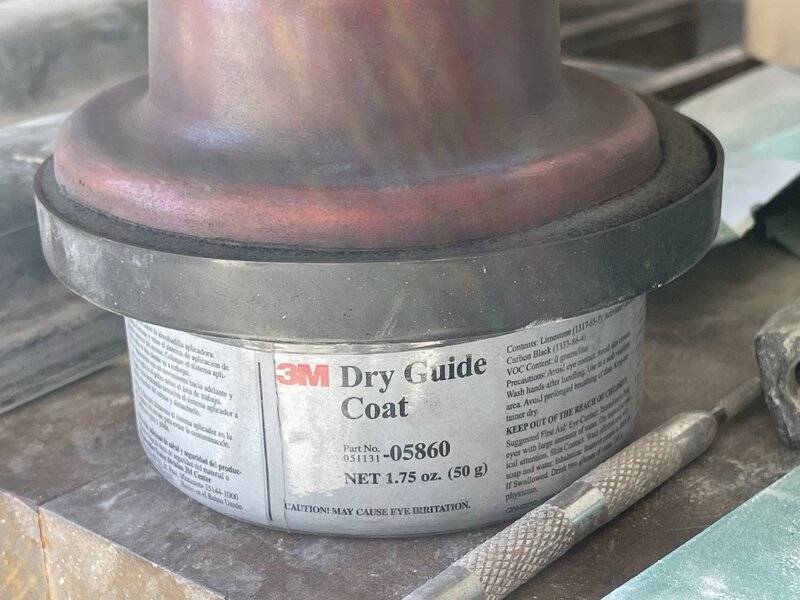

Black Epoxy so I know where to stop sanding

High Build 2k

Glaze work and more blocking

Grey Epoxy to seal the 2k and filler and more blocking

Final Blocking

Grey Epoxy for the final

there is probably one more coat of epoxy in there somewhere to restart the windows to apply filler/glaze/ something as well

Seems about typical for what I do

Last edited:

I have been watching and enjoying this whole thread. Jim you are doing such a great job, I wish I had the skills you have. It’s been fun to watch, I can’t wait to see it done!

500 feet of seam sealer…. Will go over it with a few coats of epoxy tomorrow.

Can you come and caulk my bathroom tile? I always make a mess.

-