Mad Mechanic

Member

Hello everyone.

I have a '64 Dart hardtop model and recently purchased a 3-point seatbelt kit from Seatbelts Plus. This kit is designed to have the should anchor mounted where the factory coat hanger hook is located above the rear quarter window.

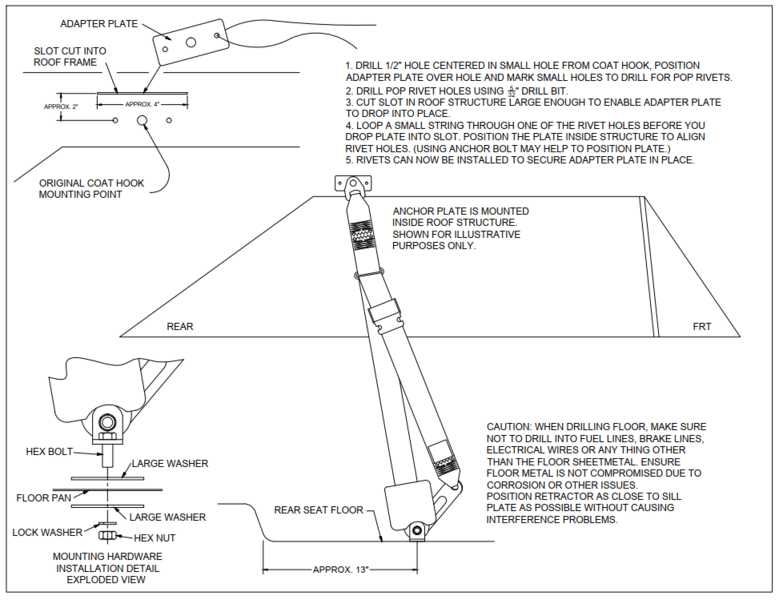

Seatbelts Plus has instructions, but they aren't very good (in my opinion) which involve drilling out the coat hanger hook mounting hole to 1/2", then cutting a slot above this to slip the backing plate through, down behind the sheet metal. I have reservations about this approach.

I have already used the search function on the forum trying to find a solution or method that others have used in my position, but most discussions end up with people using 3-point kits that mount the shoulder anchor below the rear quarter glass instead of above the window.

I already have this kit and want to use it, so please no responses telling me to go buy a different seatbelt kit.

Attached are the instructions I was able to find on Seatbelt Plus' website, they don't even include these in the box, which is disappointing.

I do own a welder, so in theory I could weld the anchor plate into position. My concern with that is ruining the paint on the roof of my car from heat dispersion.

Please let me know if you have used a kit like this and how you installed it.

Thank you.

I have a '64 Dart hardtop model and recently purchased a 3-point seatbelt kit from Seatbelts Plus. This kit is designed to have the should anchor mounted where the factory coat hanger hook is located above the rear quarter window.

Seatbelts Plus has instructions, but they aren't very good (in my opinion) which involve drilling out the coat hanger hook mounting hole to 1/2", then cutting a slot above this to slip the backing plate through, down behind the sheet metal. I have reservations about this approach.

I have already used the search function on the forum trying to find a solution or method that others have used in my position, but most discussions end up with people using 3-point kits that mount the shoulder anchor below the rear quarter glass instead of above the window.

I already have this kit and want to use it, so please no responses telling me to go buy a different seatbelt kit.

Attached are the instructions I was able to find on Seatbelt Plus' website, they don't even include these in the box, which is disappointing.

I do own a welder, so in theory I could weld the anchor plate into position. My concern with that is ruining the paint on the roof of my car from heat dispersion.

Please let me know if you have used a kit like this and how you installed it.

Thank you.