I have a water leak on the driver's side that drips down on / near the fuse box.

It seems to be worse when the wipers are running.

So I finally bit the bullet and got to fixing the pivot.

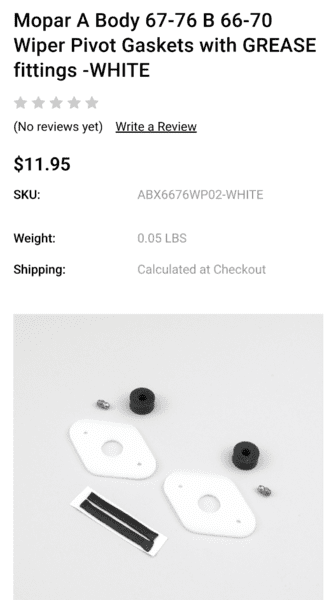

I bought the kit from Detroit Muscle Technologies, LLC Mopar & AMC muscle car restoration gaskets

I'm always happy with their products!

Before removing the drivers side pivot I had my wife help me remove the front bench seat. 4 nuts and I have all the room in the in the world, no contortionist for this old fart!

I bought a proper wiper arm removal tool, so simple, no damage! (At the last paint job they painted the splines, making removal by hand impossible)

Next I laid down on the spacious floor. Looked up and there it was. Looks simple enough! Got out a 1/2" socket, socket wrench, a universal, and an extension.

I disconnected the steering column connector and the screw holding the fuse box to the dash.

I unlatched the hazard blinker and moved everything out of the way.

I disconnected the linkages.

I put the socket on the pass side nut and turned it about 15 degrees. Then it stopped. I pulled the socket off and rotated it a few degrees and put it back on. I got another 15 degrees. I assumed the universal was binding as the angle was pretty steep.

WTF...

Then I realized I could get a box end wrench on the nut.

Got my wratchting box wrench and went to town.

Next WTF moment...

Why did they use locking nuts on these studs? A lot of force needed to remove these nuts, I was worried about spinning the stud.

I finally got the nuts off and the pivot out.

The upper rubber bushing just crumbled.

The white gasket came off in one piece and was in good shape.

I cleaned up the pivot and set about to install a zerk.

Unfortunately the instructions did not say what size hole to drill.

The location was easy, I had marked it before removal.

I test drilled some PVC pipe with various size holes and ended up with one that looked like it would work.

I drilled the hole in the pivot making sure it was far enough from the base so the grease gun could fit on.

After several failed attempts to get the zerk started I finally got it in, crooked but it's in and does not leak.

I greased it up till it JUST started to come out the upper end of the shaft.

I assembled the gaskets and the rubber sealer, put the pivot in place and started the nuts.

The pass side nut started to get real stiff to turn, I fully expected it to snap the stud, but I kept at it and finally got it tightened enough, the drivers side was easy, plenty of resistance, but not like the drivers side.

After I got it all snugged up, I checked the pivot at the cowl, it was way off center.

3rd WTF moment...

Did I do something wrong? Was it like that and I did not remember it?

I looked under the dash again and saw that I put the pivot in with the zerk facing the wrong way, AND I thought I checked that!

Crap crap crap, I figured the reason the pivot was not centered was that the pivots have an up and a down, tilting the pivot slightly one way or the other.

So now I have to remove the nuts and rotate the pivot 180.

Not looking forward to removing the pass side nut that was excessively stiff, but I had no option. So I started and lucky it came off easily. I also discovered that a 3/8" drive with a 1/2" socket fit in the dash and was much easier to remove the nuts with.

I got it off but in the process destroyed the rubber sealer and the white gasket.

Not to worry I had the passenger side parts to use.

I cleaned everything up again and reinstalled, this time I swapped the nuts side to side and for some reason they tightened up easily enough.

Once I had the nuts snugged I went up top to see how the post was now centered,

4TH WTF moment...

The pivot was off center much like before.

Then the lightbulb went off in my head.

The pivot can be adjusted by tightening one side more than the other.

The second light bulb was the reason for the lock nuts. They are needed to allow the pivot to be tightened to the cowl but with the ability to be adjusted. You are not tightening the pivot flat to the mounting surface you are tightening it enough and on both sides to center it and tight enough to compress the gasket for a water tight seal!

I inlisted my wife to watch the pivot as I tightened the nuts a little here a little there and got it centered.

I put the linkage and the electrical back together, now for a test run. I turned the switch and nothing

5th WTF moment...

What now! I start poking and thinking then turned the key to to ACC.

DUUUUHHHHH!

Everything is working as planned.

everything all put back together.

No idea if it fixed anything.

sorry for the LONG winded post.

things I learned...

It seems to be worse when the wipers are running.

So I finally bit the bullet and got to fixing the pivot.

I bought the kit from Detroit Muscle Technologies, LLC Mopar & AMC muscle car restoration gaskets

I'm always happy with their products!

Before removing the drivers side pivot I had my wife help me remove the front bench seat. 4 nuts and I have all the room in the in the world, no contortionist for this old fart!

I bought a proper wiper arm removal tool, so simple, no damage! (At the last paint job they painted the splines, making removal by hand impossible)

Next I laid down on the spacious floor. Looked up and there it was. Looks simple enough! Got out a 1/2" socket, socket wrench, a universal, and an extension.

I disconnected the steering column connector and the screw holding the fuse box to the dash.

I unlatched the hazard blinker and moved everything out of the way.

I disconnected the linkages.

I put the socket on the pass side nut and turned it about 15 degrees. Then it stopped. I pulled the socket off and rotated it a few degrees and put it back on. I got another 15 degrees. I assumed the universal was binding as the angle was pretty steep.

WTF...

Then I realized I could get a box end wrench on the nut.

Got my wratchting box wrench and went to town.

Next WTF moment...

Why did they use locking nuts on these studs? A lot of force needed to remove these nuts, I was worried about spinning the stud.

I finally got the nuts off and the pivot out.

The upper rubber bushing just crumbled.

The white gasket came off in one piece and was in good shape.

I cleaned up the pivot and set about to install a zerk.

Unfortunately the instructions did not say what size hole to drill.

The location was easy, I had marked it before removal.

I test drilled some PVC pipe with various size holes and ended up with one that looked like it would work.

I drilled the hole in the pivot making sure it was far enough from the base so the grease gun could fit on.

After several failed attempts to get the zerk started I finally got it in, crooked but it's in and does not leak.

I greased it up till it JUST started to come out the upper end of the shaft.

I assembled the gaskets and the rubber sealer, put the pivot in place and started the nuts.

The pass side nut started to get real stiff to turn, I fully expected it to snap the stud, but I kept at it and finally got it tightened enough, the drivers side was easy, plenty of resistance, but not like the drivers side.

After I got it all snugged up, I checked the pivot at the cowl, it was way off center.

3rd WTF moment...

Did I do something wrong? Was it like that and I did not remember it?

I looked under the dash again and saw that I put the pivot in with the zerk facing the wrong way, AND I thought I checked that!

Crap crap crap, I figured the reason the pivot was not centered was that the pivots have an up and a down, tilting the pivot slightly one way or the other.

So now I have to remove the nuts and rotate the pivot 180.

Not looking forward to removing the pass side nut that was excessively stiff, but I had no option. So I started and lucky it came off easily. I also discovered that a 3/8" drive with a 1/2" socket fit in the dash and was much easier to remove the nuts with.

I got it off but in the process destroyed the rubber sealer and the white gasket.

Not to worry I had the passenger side parts to use.

I cleaned everything up again and reinstalled, this time I swapped the nuts side to side and for some reason they tightened up easily enough.

Once I had the nuts snugged I went up top to see how the post was now centered,

4TH WTF moment...

The pivot was off center much like before.

Then the lightbulb went off in my head.

The pivot can be adjusted by tightening one side more than the other.

The second light bulb was the reason for the lock nuts. They are needed to allow the pivot to be tightened to the cowl but with the ability to be adjusted. You are not tightening the pivot flat to the mounting surface you are tightening it enough and on both sides to center it and tight enough to compress the gasket for a water tight seal!

I inlisted my wife to watch the pivot as I tightened the nuts a little here a little there and got it centered.

I put the linkage and the electrical back together, now for a test run. I turned the switch and nothing

5th WTF moment...

What now! I start poking and thinking then turned the key to to ACC.

DUUUUHHHHH!

Everything is working as planned.

everything all put back together.

No idea if it fixed anything.

sorry for the LONG winded post.

things I learned...

- There is little need to remove the fuse box or disconnect the steering column connector.

- Removing the seat is a god send

- 1/2 socket on the end of a 3/8 drive fits easily in to remove the nuts.

- The post is adjusted by the nuts, do not tighten them up completely, leave some slack and have some one watch as you tighten them to keep the shaft centered.

- The zerk needs a particular sized drill bit #3 (7/32) about 0.213"

- A 1/4-28 tap might be the ticket to get it started

- The zerk supplied needs a 9/32" socket, a 7mm fit well.

- Trying to get the zerk in straight was a pain.

- The instructions say use soap to get the black seal over the splined shaft.

- I used a long 3/8" 1/4 drive socket to start the seal and slid it down onto the splined shaft, then past to the pivot shaft.

- The seal does not move but the shaft it touches does, so I put some lithium grease on it.

Last edited: