Aaron

Well-Known Member

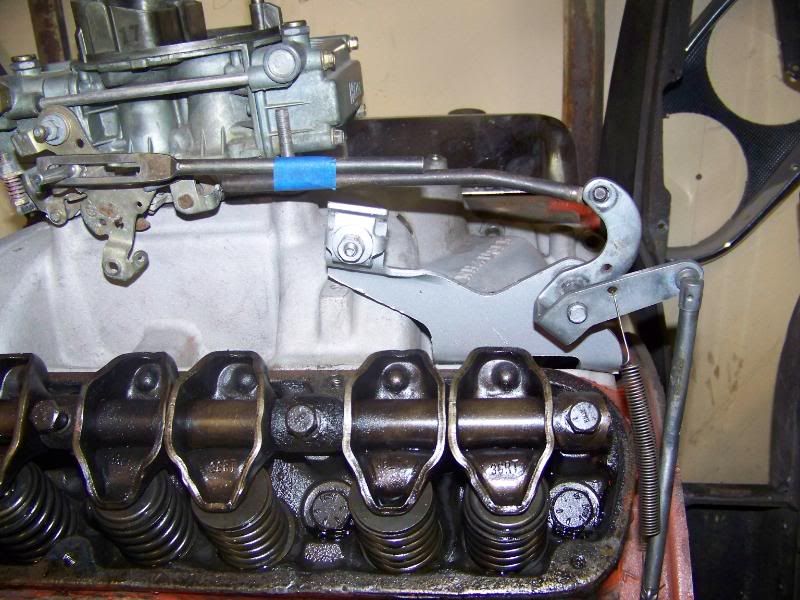

I installed a TCI sizzler 727 in my duster.

The question I have is, how late should third gear apply when you have the kickdown adjusted properly?

I installed a 2500rpm stall also, 1st and 2nd gear feel great and shift nice. Right now, around town I dont even get into third gear as it is. Its not until I go around 50 or higher (I need a new speedo cable, so this is a guess) that it goes into third. I first setup the car with the kickdown adjusted to factory instructions (loosen bolt, press lever forward to take up play, tighten bolt). I also tried it a little less to see if that helped(somewhat closer to the middle of the adjustment). But not a whole lot of change (I think the shifts were a little later even then). I understand that this tranny does have some sort of improved valve body or kit or something, but is this pretty normal operation? I used type F fluid when i filled the tranny (b&m trick shift), level is good in neutral, should I try a different fluid maybe?

Thanks

The question I have is, how late should third gear apply when you have the kickdown adjusted properly?

I installed a 2500rpm stall also, 1st and 2nd gear feel great and shift nice. Right now, around town I dont even get into third gear as it is. Its not until I go around 50 or higher (I need a new speedo cable, so this is a guess) that it goes into third. I first setup the car with the kickdown adjusted to factory instructions (loosen bolt, press lever forward to take up play, tighten bolt). I also tried it a little less to see if that helped(somewhat closer to the middle of the adjustment). But not a whole lot of change (I think the shifts were a little later even then). I understand that this tranny does have some sort of improved valve body or kit or something, but is this pretty normal operation? I used type F fluid when i filled the tranny (b&m trick shift), level is good in neutral, should I try a different fluid maybe?

Thanks