Hi Folks

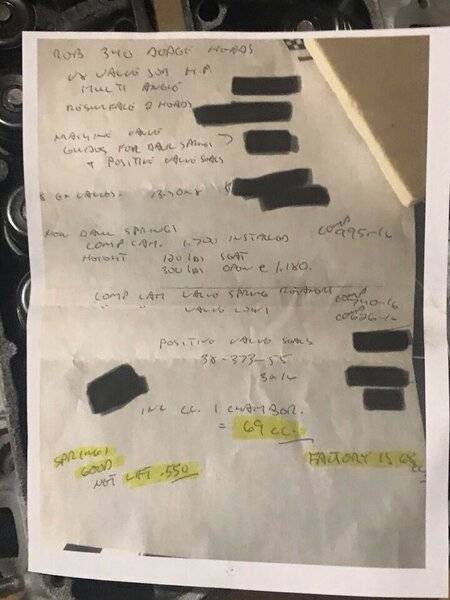

Could i get a consensus from experience how much re-surfacing a head can take before the intake needs to be "worked"? Looking at a fresh set of O castings that have been re-surfaced. The combustion chambers were cc'd at 69. Thanks for the help.

Could i get a consensus from experience how much re-surfacing a head can take before the intake needs to be "worked"? Looking at a fresh set of O castings that have been re-surfaced. The combustion chambers were cc'd at 69. Thanks for the help.