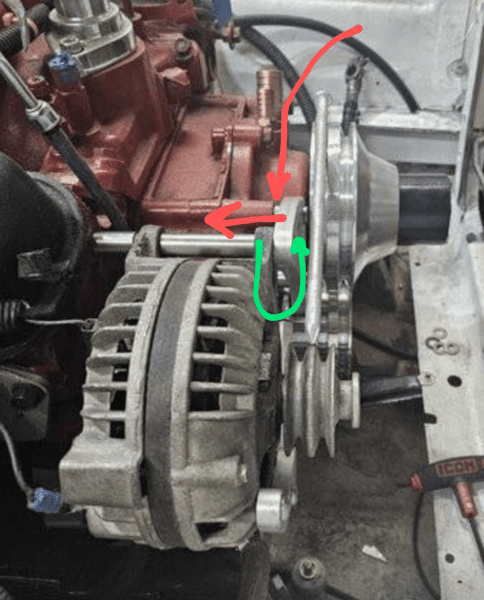

Happy New Year...I know there must be a simple solution to this...My alternator pulley just doesn't seem to line up well with the crank and fan pulley. I've attempted to use the stock set up and this new aluminum with tensioner. It is the original slanty alternator.. the pulleys should be the same right? The grooves are off..the large nail shows the difference. Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alternator line up

- Thread starter cmac64dart

- Start date

-

Professor Fate

Push the button, Max...

Well, I don't know about your aluminum aftermarket bracket, but all the stock setups I've seen have the alternator mounting ear in front of the bracket.

Looks like you've got spacers between your bracket and the water pump- I'd ditch the spacers and mount the alternator in front of the bracket; that looks like it would bring things right into alignment.

Looks like you've got spacers between your bracket and the water pump- I'd ditch the spacers and mount the alternator in front of the bracket; that looks like it would bring things right into alignment.

I'll give it a try...I originally set it up stock and then aluminum without spacers. I could have made it worse when I put the kit supplied spacers..thanks

One issue you may be having is brackets for pre 70 cast iron water pumps and pulleys for post 69 water pumps.

Or visa versa or some combinations there of

Or visa versa or some combinations there of

Thoughts

There seems to be space behind the bracket (large red arrow)

If that space is removed the bracket can move backwards (small red arrow)

Then put alternator on the other side of the bracket (green arrow)

There seems to be space behind the bracket (large red arrow)

If that space is removed the bracket can move backwards (small red arrow)

Then put alternator on the other side of the bracket (green arrow)

Yes I already tried it without the spacers. I don't have pictures when I did this but it doest line up then either...the sleeves that the swing bolt go thru are pre cut to fit.Everything on it is for the newer waterpump setup not the pre 70.I will mess with it tomorrow if time allowsThoughts

There seems to be space behind the bracket (large red arrow)

If that space is removed the bracket can move backwards (small red arrow)

Then put alternator on the other side of the bracket (green arrow)

View attachment 1716186456

You need to get rid of all the crap *** billet junk and get the correct factory brackets. It's still not gonna work with the alternator in front of that billet bracket, because the bracket is too thick and will throw the alternator too far forward. Lose the junk and it will work fine.

I agree with Rusty, altho factory setups are getting harder to find, waayyyy less BS with them setting them up. Is the alt a square back(70+)or round back(69 down)?

Pretty cheap actually

70-76 A/B/C/E-body Mopar Small Block 318 340 360 Alternator Bracket Kit-New | eBay

70-76 A/B/C/E-body Mopar Small Block 318 340 360 Alternator Bracket Kit-New | eBay

Scody21

Just send it

I have the March set up with a Be-Cool radiator and twin sucker fans in my 340 duster and it is tight, like 5/16 or 7/16 tight from the water pump pulley to the fans. And the bracket is set like you have going on.

Not sure on your brand of pulley kit…

Not sure on your brand of pulley kit…

I would suggest that you quit trying to eyeball stuff with a nail. get a real straight edge (an 18 or 24 inch level) and lay it flat on the face of the alternator pulley (not the thing that sticks out of the face of the pulley) and see how far off you are from the other pulleys. Measure it. Then you will know if you can move to the other side of the outer alternator bracket, or how far you need to shim all the alternator brackets to reach your goal. I just had to do a lot of this to align a poorly designed pulley system for a small block with aftermarket AC, water pump, 2 groove alternator and power steering. You can do this if you know how far from aligned you are.

by the way, it seems odd that the grooves on the aluminum pulleys are spaced so far apart (1/4 inch?), when the factory pulley you are trying to align with they are butted right up against each other. Does the pulley manufacturer offer to revised alternator pulley with the same configuration? how far apart are the centers of the grooves on the aluminum pulleys? I think that the factory distance on a double groove pulley is 1/2 inch.

69 and down...I was wondering if this would be an issueI agree with Rusty, altho factory setups are getting harder to find, waayyyy less BS with them setting them up. Is the alt a square back(70+)or round back(69 down)?

.

by the way, it seems odd that the grooves on the aluminum pulleys are spaced so far apart (1/4 inch?), when the factory pulley you are trying to align with they are butted right up against each other. Does the pulley manufacturer offer to revised alternator pulley with the same configuration? how far apart are the centers of the grooves on the aluminum pulleys? I think that the factory distance on a double groove pulley is 1/2 inch.

It does come with a aluminum pulley...I didn't install it because the factory looks so far off..it doesn't appear that changing it would make a difference...Would a newer alternator change this line up? That is the original slanty alt ..I guess I can get a napa 360 alternator post 1970 and see if that changes anything. As far as using stock equipment I have it...It didn't change the line up issue with either sets of pulleys / brackets..Which leads me to believe the earlier alt was different..I was looking for conformation of this.by the way, it seems odd that the grooves on the aluminum pulleys are spaced so far apart (1/4 inch?), when the factory pulley you are trying to align with they are butted right up against each other. Does the pulley manufacturer offer to revised alternator pulley with the same configuration? how far apart are the centers of the grooves on the aluminum pulleys? I think that the factory distance on a double groove pulley is 1/2 inch.

That could possibly be contributing to the head scratching. Honestly switch to 70 and up alt and vr etc.(more reliable). Start a want ad for complete pulleys/bracket setup, or start with the eBay link I posted above. Mixing and matching is brutal, pita and a waste of time.

I have the stock set up...I like the aluminum adjuster..I'd like to keep if I could

Round or square back the alternator pulley position is the same.

Your alignment issue is NOT the alternator.

Your alignment issue is NOT the alternator.

As far as I know the only difference in alternator pulley locations in that whole era is between AC cars (double pulley) and non-AC cars (single pulley).Would a newer alternator change this line up?

As mentioned before, the only reason to swap to the matching pulley is to solve an alignment issue between the two belts. If the belts are farther apart on two of the pulleys, and you align the outer belt, the inner belt might be off a quarter of an inch - measure and compare distances between the bottom of the grooves.

All of the eye candy billet stuff is great, "IF" it all lines up. Obviously the problem is with the billet bracket, so "I" would go back to the factory set up. Send it out and have plated or powder coated, or just paint it gloss black and be done with it. I say this from experience, I ordered all of the billet stuff from a well known manufacturer. It took three different sets before I told them to refund my money. None of it fit correctly, the bolt holes didn't line up, belts didn't run true and it was totally jacked out of shape. I blasted all of the OEM pieces, primed them and painted them gloss black. I let then sit in the sun for two days and then put then in the oven on "WARM" for 3 hours. they are still on my bracket car and look good.

junkyardhero

Well-Known Member

- Joined

- Jan 23, 2005

- Messages

- 2,971

- Reaction score

- 4,660

if you have 69 and earlier junk then none of the 70+ stuff works and everything is all fakakta when you go mixing and matching.

do you have the correct water pump on there? that could be a contributing factor; also not all pumps are the same-- some have "taller" shafts so they'll put the pulley further out.

measure the new pulley against the old one and see if that helps put everything into perspective.

i have a 69 and want to keep everything 69, so i feel your pain amigo. upgrading is a PITA and expensive.

do you have the correct water pump on there? that could be a contributing factor; also not all pumps are the same-- some have "taller" shafts so they'll put the pulley further out.

measure the new pulley against the old one and see if that helps put everything into perspective.

i have a 69 and want to keep everything 69, so i feel your pain amigo. upgrading is a PITA and expensive.

You need to get rid of all the crap *** billet junk and get the correct factory brackets. It's still not gonna work with the alternator in front of that billet bracket, because the bracket is too thick and will throw the alternator too far forward. Lose the junk and it will work

I'm almost there...I do have an original set up and something wasn't matching up. I could have mixed up old style crank or water pump pulleys when I re assembled so I decided to go this direction..As I said before I like the aluminum adjuster on itAll of the eye candy billet stuff is great, "IF" it all lines up. Obviously the problem is with the billet bracket, so "I" would go back to the factory set up. Send it out and have plated or powder coated, or just paint it gloss black and be done with it. I say this from experience, I ordered all of the billet stuff from a well known manufacturer. It took three different sets before I told them to refund my money. None of it fit correctly, the bolt holes didn't line up, belts didn't run true and it was totally jacked out of shape. I blasted all of the OEM pieces, primed them and painted them gloss black. I let then sit in the sun for two days and then put then in the oven on "WARM" for 3 hours. they are still on my bracket car and look good.

lay out your original stuff and post a pic and we can probably eyeball it for a mismatch. I'll try and take a picture of the parts for a whole set up for the 70 and up water pump. One installed and one set laid out on a bench.

Ok.thanks..

Pics

BTW that crank and water pump pulleys will overdrive your water pump.

Might not be an issue but something you need to be aware of.

Might not be an issue but something you need to be aware of.

-