I have a full quarter skin I'm putting on my 72 duster and I also did a rocker since it was farther gone than I thought.

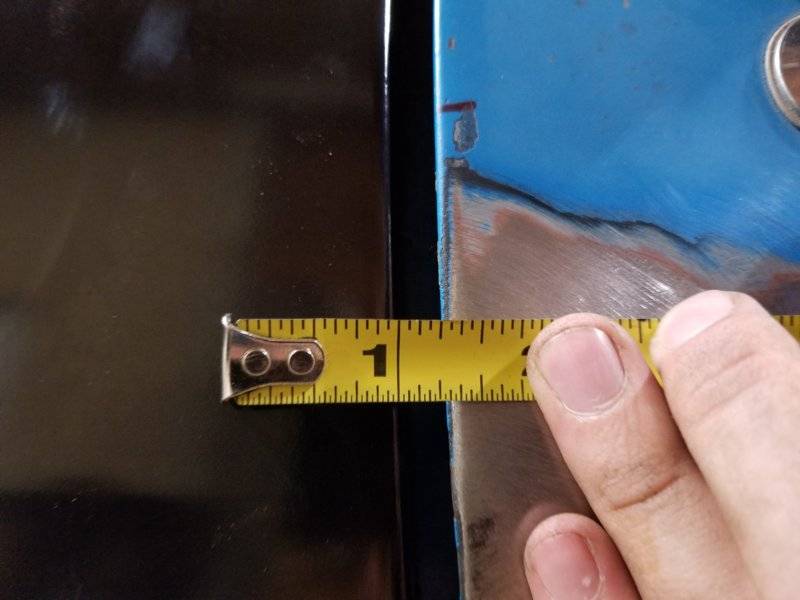

The problem is the top door gap it is alot bigger than the rest and I'm trying to figure out what might be holding it out.

Overall the rest of door gap is barely bigger than the original.

Here are some pictures.

The quarter seems to be lining up fairly well every where else and the body lines seem to be good.

I did not get the car as braced as I probably should have since I didn't know I was going to end up doing a full rocker as well and i did have to brace the front door post after the fact since it was trying to move.

Let me know if I need to post any other pictures and I do have some from before as well if that will help.

The problem is the top door gap it is alot bigger than the rest and I'm trying to figure out what might be holding it out.

Overall the rest of door gap is barely bigger than the original.

Here are some pictures.

The quarter seems to be lining up fairly well every where else and the body lines seem to be good.

I did not get the car as braced as I probably should have since I didn't know I was going to end up doing a full rocker as well and i did have to brace the front door post after the fact since it was trying to move.

Let me know if I need to post any other pictures and I do have some from before as well if that will help.