mopowers

Well-Known Member

I bought my first lathe last year - an old Atlas Craftsman 12". Every time I've tried oiling the lube points at the small ball oilers, it makes a mess. I'm wondering if the tip on my oil can is the wrong tip for these ball oilers.

Is this the wrong tip to be using on these tiny ball oilers?? Do you have any tips for making this oil can tip seat well enough at the ball oiller to transfer a little oil without making a mess?

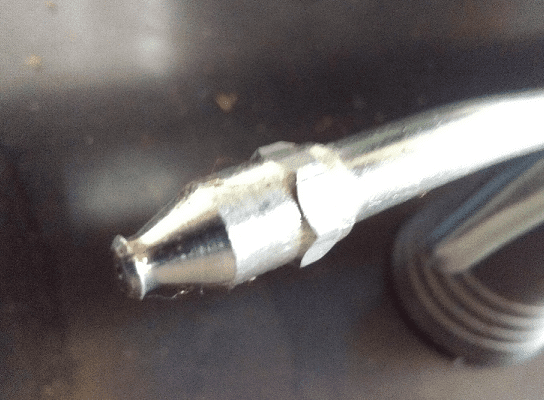

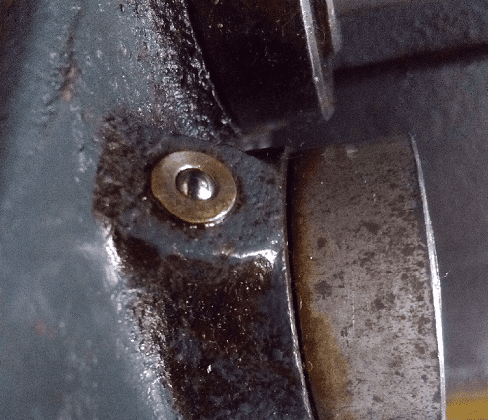

Here's the tip on my goldenrod oil can and the ball oilers I'm referring to:

Is this the wrong tip to be using on these tiny ball oilers?? Do you have any tips for making this oil can tip seat well enough at the ball oiller to transfer a little oil without making a mess?

Here's the tip on my goldenrod oil can and the ball oilers I'm referring to: