3406pk

Well-Known Member

Had an unpleasant surprise a week ago. Checked the Duster 408 over to prep for drag races coming up. Checked the oil and it was way over full. Then checked radiator and it was below cores. OH OH, knew I had a problem. I had run it at drag races 2 weeks before and ran fine; just unloaded from trailer and parked in garage.

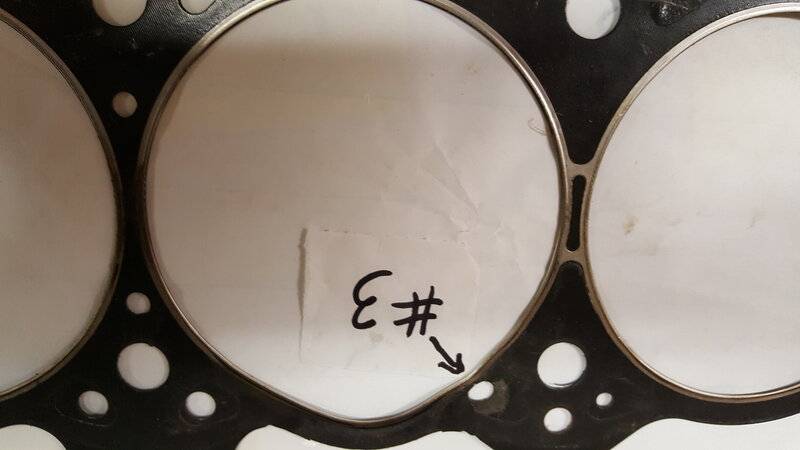

So pressurized the cooling system and could hear air leaking into #3 cylinder. Leakdown test was still ok for that cyl and really good for all the rest. Decided to pull that left head first and spotted the problem right away. The compression ring on gasket pushed out and caused water port to leak to lifter valley. Was hoping the gasket was only problem, so took head to machine shop to crack check and look at valves.

Cut oil filter and check for metal, was good. Whew that's a relief. Put in some oil and drove oil pump w drill to flush out water from passages and roller lifters. Cam and roller lifters still look good. Am glad I put in roller cam instead of flat tappet for this incident. Head checked out ok, he did skim cut on head surface and touched up one valve. Pistons look great so good to go.

Well I got lucky on that one. The head gasket was Felpro 1008 and had been in 3 years, and before that refresh was 10 years on same part number gasket. Is this gasket failure common or unusual?

It is a 10.5:1 CR, running on 91 pump gas. Pistons and spark plugs all good.

It is a 10.5:1 CR, running on 91 pump gas. Pistons and spark plugs all good.

I now realize that I had a warning as I found small amount of water in the oil separator in the PCV hose line.

So pressurized the cooling system and could hear air leaking into #3 cylinder. Leakdown test was still ok for that cyl and really good for all the rest. Decided to pull that left head first and spotted the problem right away. The compression ring on gasket pushed out and caused water port to leak to lifter valley. Was hoping the gasket was only problem, so took head to machine shop to crack check and look at valves.

Cut oil filter and check for metal, was good. Whew that's a relief. Put in some oil and drove oil pump w drill to flush out water from passages and roller lifters. Cam and roller lifters still look good. Am glad I put in roller cam instead of flat tappet for this incident. Head checked out ok, he did skim cut on head surface and touched up one valve. Pistons look great so good to go.

Well I got lucky on that one. The head gasket was Felpro 1008 and had been in 3 years, and before that refresh was 10 years on same part number gasket. Is this gasket failure common or unusual?

I now realize that I had a warning as I found small amount of water in the oil separator in the PCV hose line.