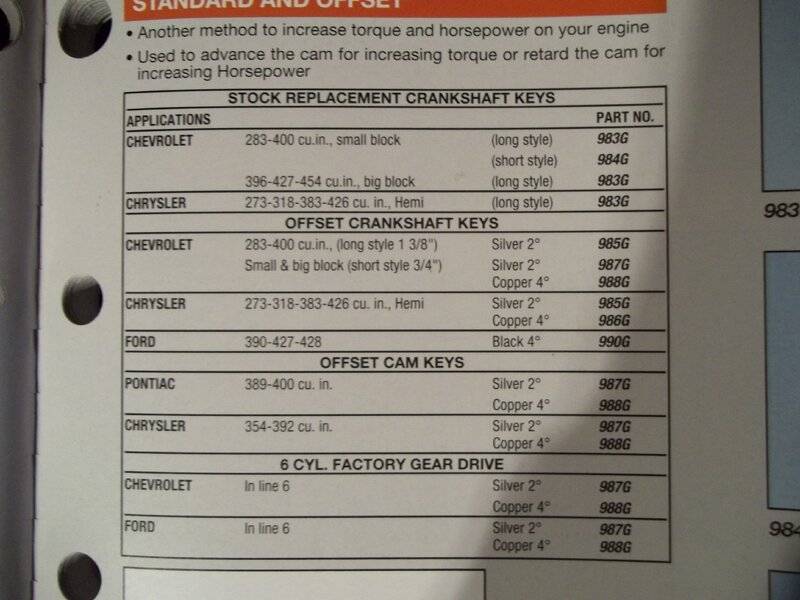

Where you'll be running into a math issue is because MrGasket is not exactly describing their product correctly! That very same 988G is used on SBC crank applications and other applications, yet is still called a 4 degree key. It can't change 4 degrees on a chev crank AND change 4 degrees on a Mopar camshaft, and then expect the same result of change (in crankshaft degrees) on the Mopar crank.

Last edited: