C2ndLTpigeon

Mopar or no Car!

I am mocking up the rocker arms on my 340. I am using a set of Crane 1.5 rocker arms that came with the engine I purchased. I am running a Mechanical solid cam.

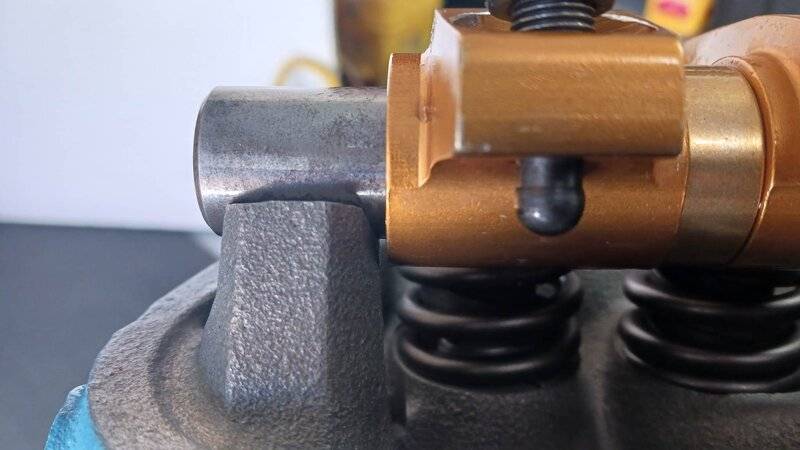

My issue is during installation I am noticing that the outer arm on for the number 1 Exhaust is rubbing the shaft mounting tower. This is not allowing the second bolt in to screw in all the way as it there is pressure from the rocker rubbing. This is not an issue on the opposite side head and I have taken this shaft with rockers and swapped it to the other side with no issue. Which is making me believe that this heads casting may be a little bit wider on that tower? Can anyone confirm that this is the issue? If so is it as simple as grinding some of the tower back so that the rocker arm clears?

Here are some pictures.

Here is the passenger side with no issue, and same shaft swapped but clears fine.

My issue is during installation I am noticing that the outer arm on for the number 1 Exhaust is rubbing the shaft mounting tower. This is not allowing the second bolt in to screw in all the way as it there is pressure from the rocker rubbing. This is not an issue on the opposite side head and I have taken this shaft with rockers and swapped it to the other side with no issue. Which is making me believe that this heads casting may be a little bit wider on that tower? Can anyone confirm that this is the issue? If so is it as simple as grinding some of the tower back so that the rocker arm clears?

Here are some pictures.

Here is the passenger side with no issue, and same shaft swapped but clears fine.