blue missile

Well-Known Member

I posted in the wrong forum, this is the right place

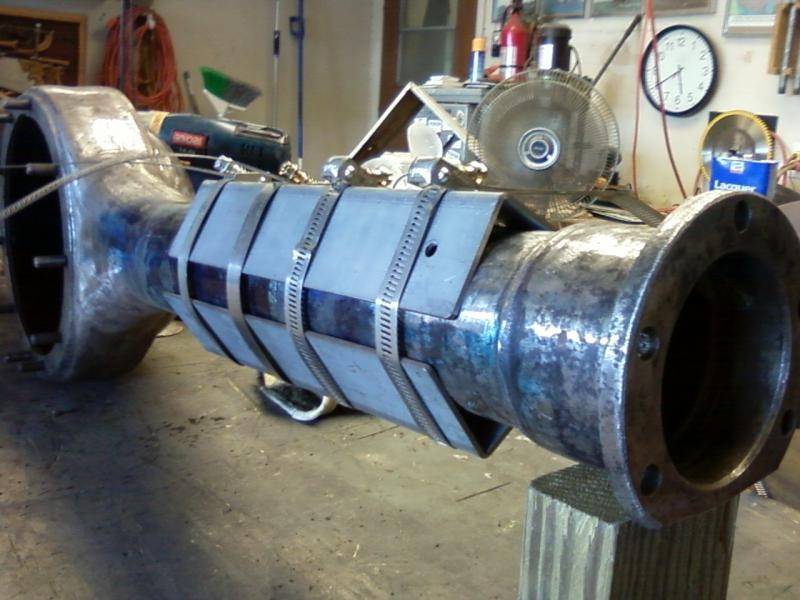

I thought I would post pics of the B-sectomy.

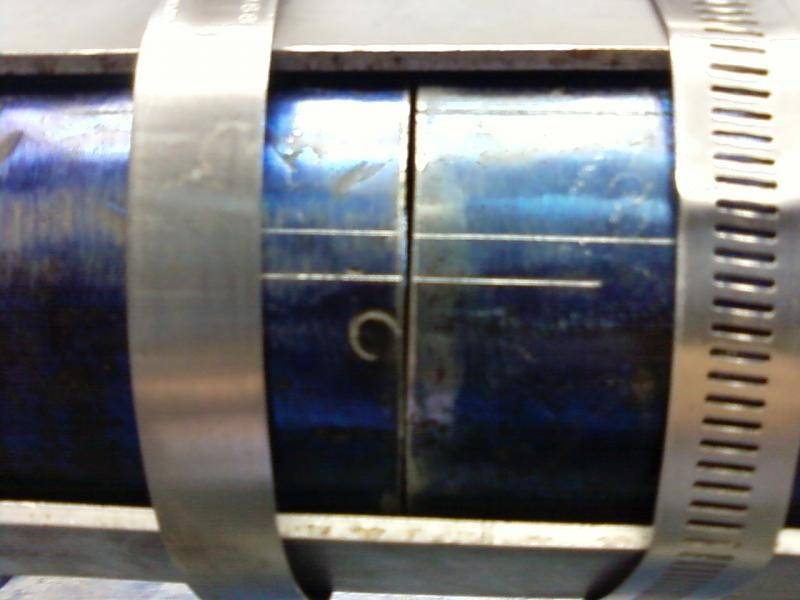

After measuring the axle tube and figuring out how much needed to be removed from the length of each side I blued and scribed two lines around the tube with the amount to be removed between them.

I also scribed indexing lines on each side, and cut out the sections to be removed with a 4" grinder.

I then used an old woodworking trick for clamping dowels.

Using two pieces of angle and four long hose clamps i reassembled the pieces. I lined up the index lines and left enough space between the angles to get really good surface welds on two sides of each half (tacks).

I then removed all the angles and ground a double fillet (vee groove) along the seam where the tacks were not.

I was careful to measure the depth with a set of mics and went 80% of the thickness of the tube wall.

After welding the groove, and making sure there was good penetration past the bottom of the groove, I ground off the tacks and repeated the process where the tacks were.

I setup the seam to be further reinforced by the 4 link bracket on each side, which will span the seam.

Andrew

I thought I would post pics of the B-sectomy.

After measuring the axle tube and figuring out how much needed to be removed from the length of each side I blued and scribed two lines around the tube with the amount to be removed between them.

I also scribed indexing lines on each side, and cut out the sections to be removed with a 4" grinder.

I then used an old woodworking trick for clamping dowels.

Using two pieces of angle and four long hose clamps i reassembled the pieces. I lined up the index lines and left enough space between the angles to get really good surface welds on two sides of each half (tacks).

I then removed all the angles and ground a double fillet (vee groove) along the seam where the tacks were not.

I was careful to measure the depth with a set of mics and went 80% of the thickness of the tube wall.

After welding the groove, and making sure there was good penetration past the bottom of the groove, I ground off the tacks and repeated the process where the tacks were.

I setup the seam to be further reinforced by the 4 link bracket on each side, which will span the seam.

Andrew