73dart360

Well-Known Member

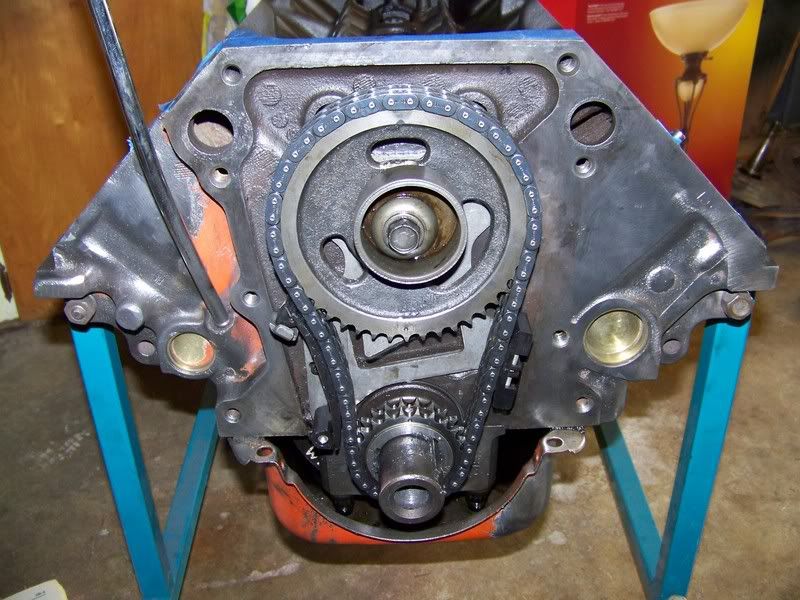

I Was Wondering Is Anybody Using A Timing Chain Tensioner On Their Stroker Motor What Benefits If Any?

Just installed one tonight, no problem to install. Anyone know why this design uses only three bolts to mount it to the block?quote]

Probably because the newer blocks only have 3 bolt holes. My 79 360 only has 3 but I have a 73 360 and had numerous 340's that all had 4 holes. So somewhere in between 73 and 79 they dropped one bolt hole. Why, who knows. Probably to save a nickel on every engine they sold. These tensioners were originally designed for the Magnum engines which only have 3 holes.