GEO

Sarcasm Inc.

So how many hours did you waste finding and posting all those pictures?:sign3:All wrong, I guess:

So how many hours did you waste finding and posting all those pictures?:sign3:All wrong, I guess:

About 1/2 hour. I guess all these motors are gonna leak oil all over the place and end up with corroded innards? I see hundreds of cars with just breathers and no PCV every week at car shows and cruise nights. Them too?So how many hours did you waste finding and posting all those pictures?:sign3:

About 1/2 hour. I guess all these motors are gonna leak oil all over the place and end up with corroded innards? I see hundreds of cars with just breathers and no PCV every week at car shows and cruise nights. Them too?

Relax, the OP asked what's the best way, best would be a PCV system of some sort like a PCV valve, or draft tube like old 40's / 50's cars, or as you know most hi hp drag race and street engines use a vacuum pump to to keep psi down and to help ring seal.About 1/2 hour. I guess all these motors are gonna leak oil all over the place and end up with corroded innards? I see hundreds of cars with just breathers and no PCV every week at car shows and cruise nights. Them too?

During World War II a different type of crankcase ventilation had to be invented to allow tank engines to operate during deep fording operations, where the normal draft tube ventilator would have allowed water to enter the crankcase and destroy the engine.[4] The PCV system and its control valve were invented to meet this need, but no need for it on automobiles was recognized.

In 1952, Professor A. J. Haagen-Smit, of the California Institute of Technology at Pasadena, postulated that unburned hydrocarbons were a primary constituent of smog, and that gasoline powered automobiles were a major source of those hydrocarbons. After some investigation by the GM Research Laboratory (led by Dr. Lloyd L. Withrow), it was discovered in 1958 that the road draft tube was a major source—about half—of the hydrocarbons coming from the automobile. GM's Cadillac Division, which had built many tanks during WWII, recognized that installation of PCV on vehicles could bring the first major reduction in automotive hydrocarbon emissions. After confirming the PCV valve's effectiveness at hydrocarbon reduction, GM offered the PCV solution to the entire U.S. automobile industry, royalty free, through its trade association, the Automobile Manufacturers Association (AMA).[citation needed] The PCV system thus became the first real vehicle emissions control device.

stop the drama. PCV is an anti-smog device and it helps keep the crankcase/valve covers cleaner inside and helps keep oil from spewing where it shouldnt. nobody's callin you stupid. yes it's an optional device. so are seat belts.

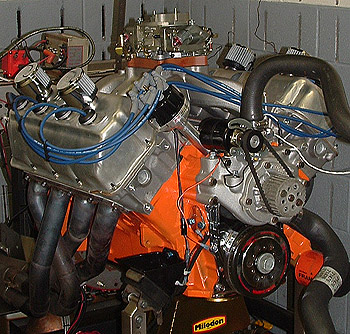

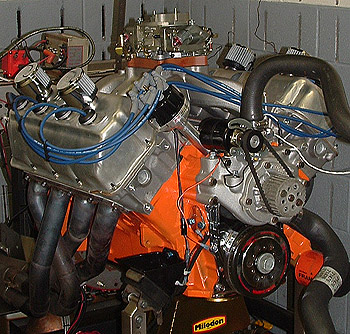

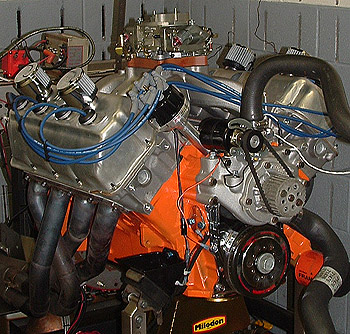

Nice pictures! Is that all your stuff?All wrong, I guess:

Stock type engine I agree on the PCV. PCV did not work for me, neither did Multiple breathers on the Valve covers. I even tig welded tubes 4" up off the valve covers then attached the breathers to them. I still had excessive crank case pressure and oil was actually getting into the cylinders past the rings..... Not good for NOS. Engine is a 410 Stroker that I rev to 7200RPM on about a 200 hit of NOS. I had to go with a Vac Pump to get it under control.

So saying that a PCV is the fix all is kind of funny.

Sounds like a ring seal problem. Are you using low tention rings?

Here's a great artical that might be helpful

http://www.enginelabs.com/engine-tech/engine/tech-crankcase-pressure-control-oil-and-air-control/