BillyJack1980

Member

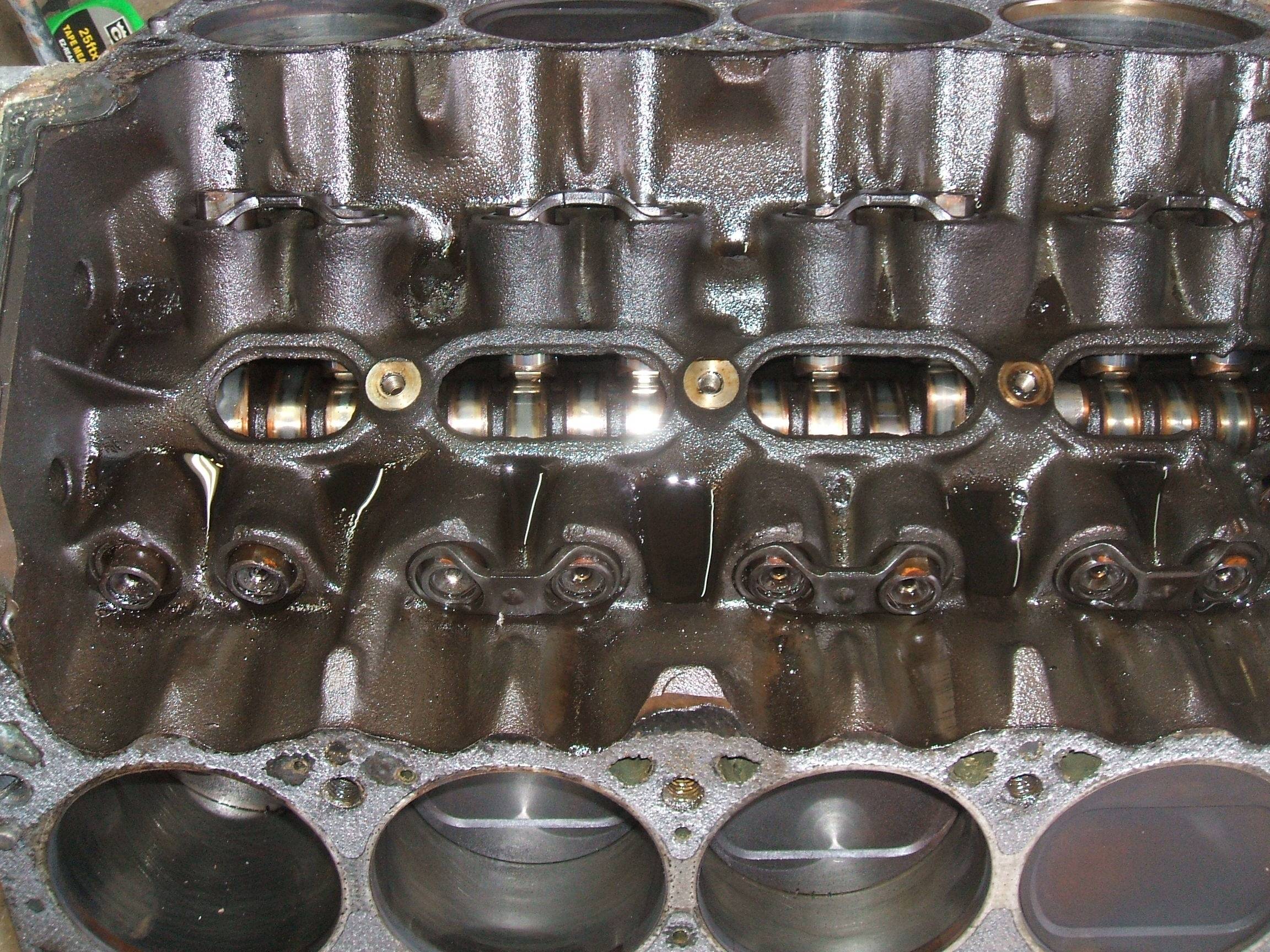

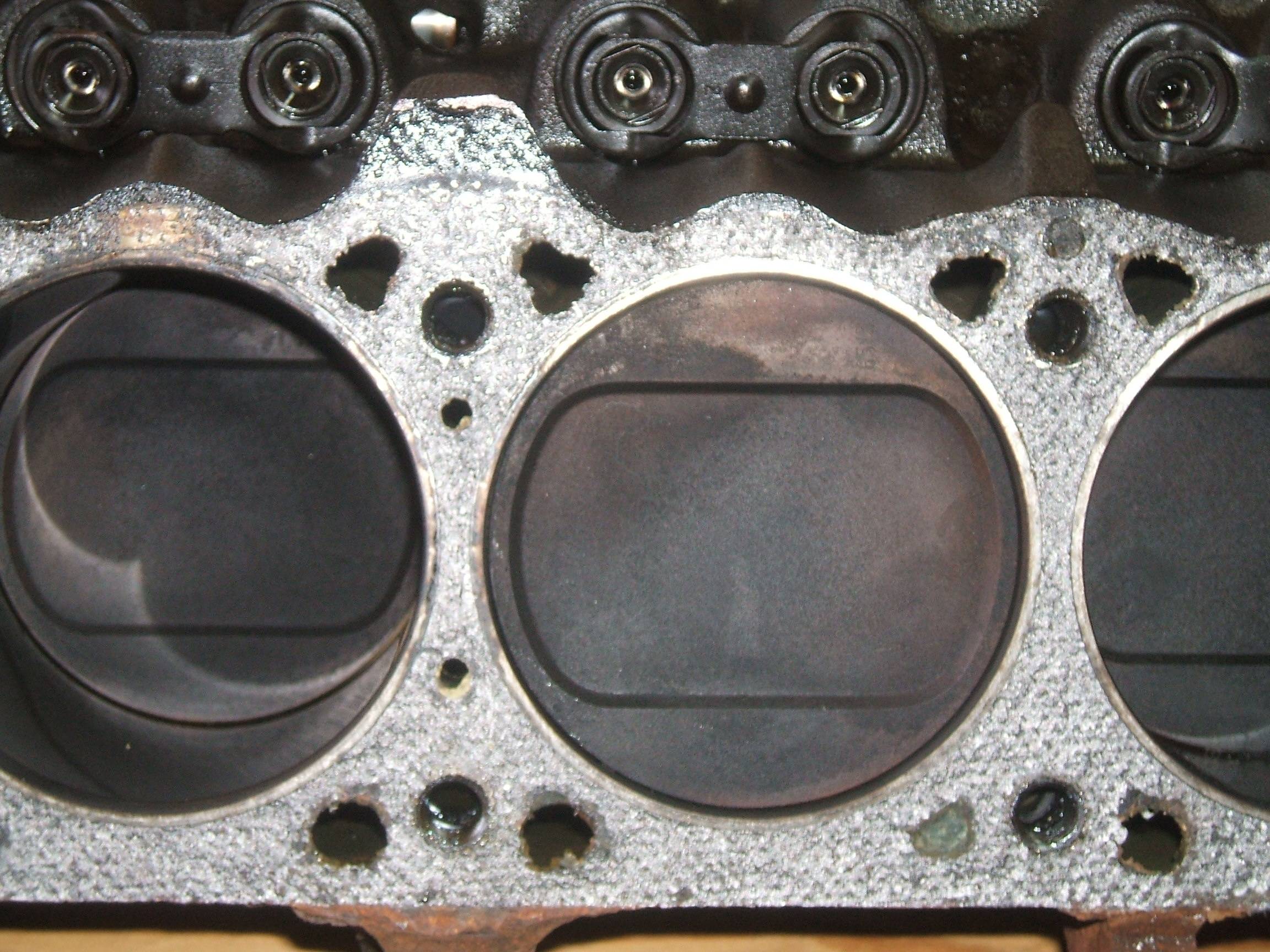

Sorry if my questions sound dumb or foolish but I really have not tore down into a motor before so before I do anything else with motor I would like to know if everything looks ok. My plan is to drop this motor into a 91 Dakota. Would like to have motor ready late winter early spring. As budget allows etc... The motor has 2 tabs on the back of the block that say void if removed. Is this a remanufactured motor? The motor was pretty dirty on the outside so after googling I cleaned it up. Then the next day starting tearing it down to a shortblock. The pistons all have a number on top that appears to say 6513- is this a part number? You can see scratches in each cylinder bore, is that ok? One piston appears to be pitted or burned a little on top. Here are some pics.