goldduster318

Overzealous Car Modifier

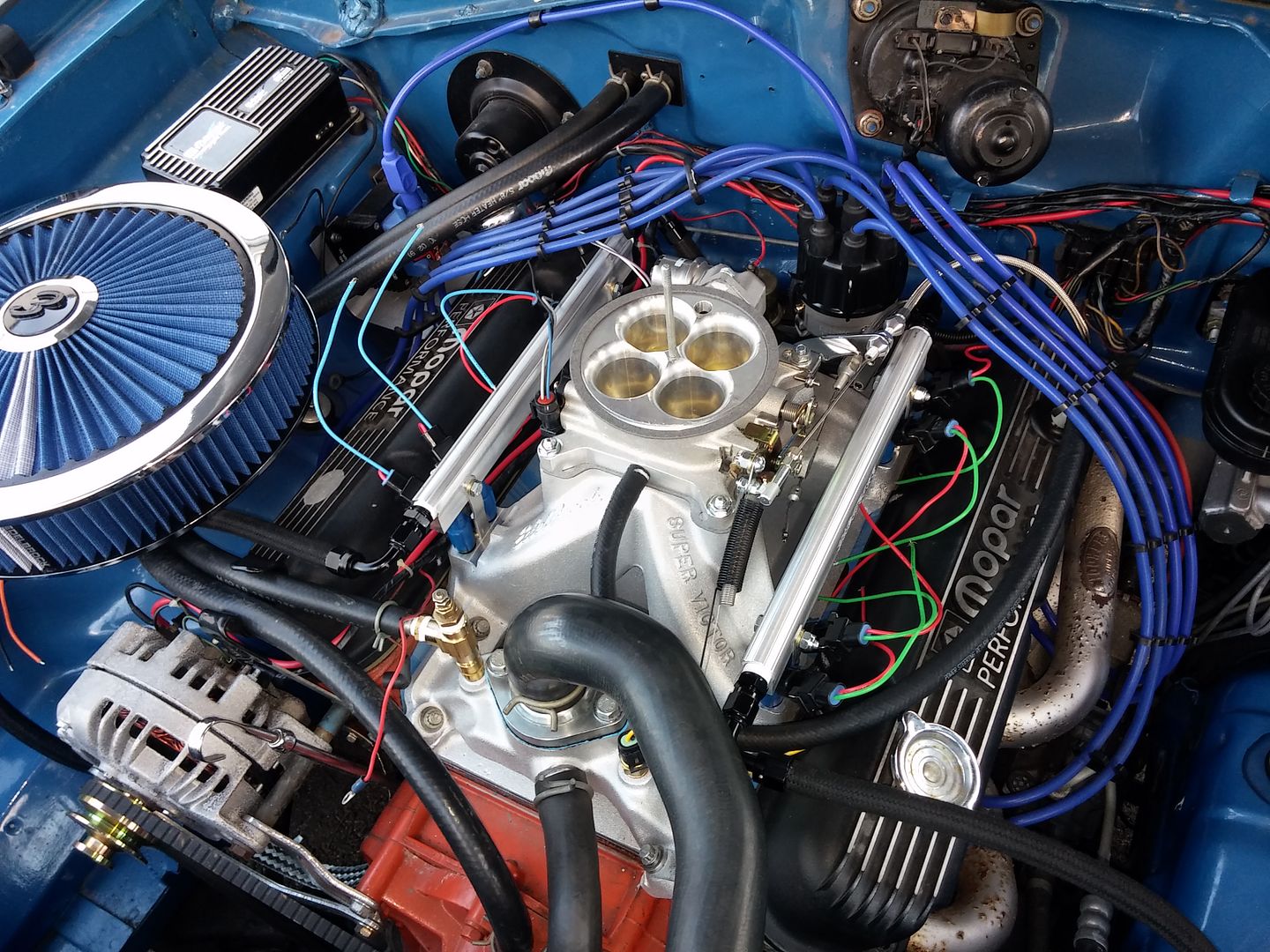

Agreed on the 36-1 crank trigger. Still working on mine - I ordered one from http://www.millersmule.com/MillersMuleStore/en/trigger-wheels/41-36-1-trigger-wheel.html and welded it to the crank pulley. I built a bracket to hold a ford 3.0L crank sensor to the oil pan rail, but if it's not stiff enough I can put it on a tab to the water pump.

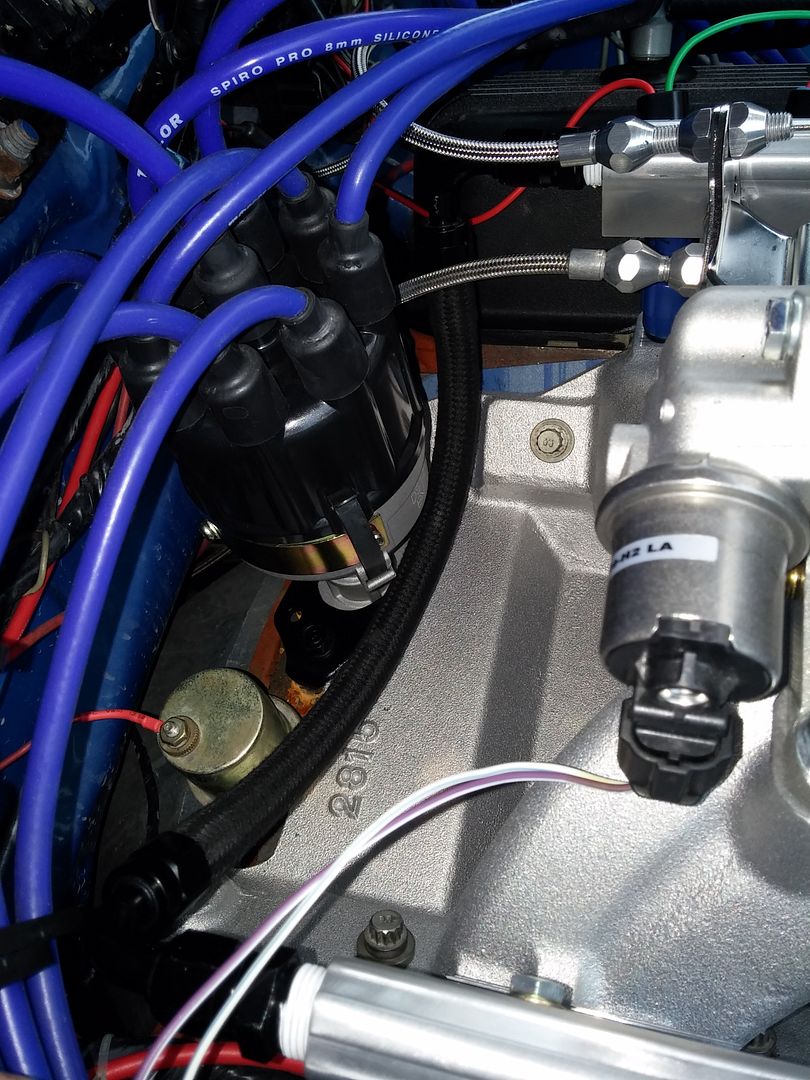

For a distributor, use a 1992+ 3.9/5.2/5.9 magnum distributor. There are no mods needed as this is just a cam sensor anyway. It's a "half moon" type which is pretty much ideal. I think I paid $10 for one of these.

I am going to be using LSX coil near plug so I'm basically capping the distributor.

For a distributor, use a 1992+ 3.9/5.2/5.9 magnum distributor. There are no mods needed as this is just a cam sensor anyway. It's a "half moon" type which is pretty much ideal. I think I paid $10 for one of these.

I am going to be using LSX coil near plug so I'm basically capping the distributor.