Currently building a shop and wanted to get y’all’s opinions on ceiling height in a metal/fab/dirty room. Will 8’ ceilings be sufficient for anything I might eventually need, like a vertical band saw?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fab room ceiling height?

- Thread starter 75slant6

- Start date

-

Will the ceiling be covered or open beam

Ideally, I’d cover the ceiling but probably be bare joists for quite awhileWill the ceiling be covered or open beam

Shop will have 16’ side walls, so I could do 9’ ceiling, which would put the loft floor at around 10’. I’m using scissor trusses, so I’d still have plenty of room in the loft.

harrisonm

Well-Known Member

IMHO, 8 would work, but 9 would be better.

Once you place everything you could box in anything that needs extra height

Professor Fate

Push the button, Max...

8' should be fine, but remember- that would be FINISHED height. Before roughing it in, consider everything that will be going above the work area: lighting, electrical supply, HVAC ductwork, exhaust/vacuum ducting, etc. to determine what your rough-in vs. finished ceiling height will be.

Span will determine what size your floor/ceiling joists will need to be, which in turn may dictate the direction of your installed joists in order to maximize and simplify the installation of any overhead utilities- I would guess it to be 9' minimum, 10' preferable in order to keep your finished ceiling at 8' or so.

Span will determine what size your floor/ceiling joists will need to be, which in turn may dictate the direction of your installed joists in order to maximize and simplify the installation of any overhead utilities- I would guess it to be 9' minimum, 10' preferable in order to keep your finished ceiling at 8' or so.

This...........above.8' should be fine, but remember- that would be FINISHED height. Before roughing it in, consider everything that will be going above the work area: lighting, electrical supply, HVAC ductwork, exhaust/vacuum ducting, etc. to determine what your rough-in vs. finished ceiling height will be.

Span will determine what size your floor/ceiling joists will need to be, which in turn may dictate the direction of your installed joists in order to maximize and simplify the installation of any overhead utilities- I would guess it to be 9' minimum, 10' preferable in order to keep your finished ceiling at 8' or so.

I have 12 ft now, to evacuate all the air is very hard, and I would think 9' max.

Thought about an I beam and a trolley hoist or gantry crane? Even an engine hoist, I'd make it taller than 8ft. What are you going to use the loft for? I think I'd figure the minimum height used in the loft and maximize the height on the ground floor. Maybe even consider the I beam/trolley for moving stuff upto the loft.

Last edited:

As mentioned, 8 feet is gonna feel really low once you start adding lights, etc. If it were my shop, I wouldn't necessarily be concerned with the height of my machines -- most floor standing vertical bandsaws are 6-7', unless you're getting a monster DoAll or something like that. My concern would be getting a gantry or hoist in there as @SIX225 said. I don't know what kind of fabrication you do, but if you're like me and work alone, something to lift and move your work will be necessary and 8' ceilings will drive you out of your mind.

Go as big as you can afford now and you'll thank yourself later.

Go as big as you can afford now and you'll thank yourself later.

Professor Fate

Push the button, Max...

If going with an I beam/trolley, I'd keep it up by the rafters, above the bay and loft. If you want to also access the "fab room", consider putting a ceiling/floor scuttle above the fab room, so you can open it up to use the trolley to lower things from above down into the fab room. Make the entry door(s) to the fab room large enough to accommodate an engine stand, consider a double door.

Professor Fate

Push the button, Max...

Yeah, that's why I said finished height of 8'- so everything can be tucked in above the finished ceiling and still have 8' clearance. No hanging lights- just troffer lights in the fab room, keep your overhead open. It may not be as critical in OP's Kentucky, but up here anything over 8' is a b**ch ($$) to keep heated in the winter, same applies to cooling in the summer. All that heating and cooling money coulda paid for those new TrickFlow heads I've been eyeballing...As mentioned, 8 feet is gonna feel really low once you start adding lights, etc. If it were my shop, I wouldn't necessarily be concerned with the height of my machines -- most floor standing vertical bandsaws are 6-7', unless you're getting a monster DoAll or something like that. My concern would be getting a gantry or hoist in there as @SIX225 said. I don't know what kind of fabrication you do, but if you're like me and work alone, something to lift and move your work will be necessary and 8' ceilings will drive you out of your mind.

Go as big as you can afford now and you'll thank yourself later.

Very good point. My shop is a Butler building and has a 16' ceiling....uninsulated. Winters down here are fine but that thing is an OVEN from about May to October. Got to have a couple fans and cooler going. But the high ceiling is great.

I’d planned on using 2x8 joists every 16”, but I just looked up a joist span chart and prices, and decided I’ll use 2x10’s 16” apart. All wiring, lighting and duct work can be kept flush with or above finished ceiling height.8' should be fine, but remember- that would be FINISHED height. Before roughing it in, consider everything that will be going above the work area: lighting, electrical supply, HVAC ductwork, exhaust/vacuum ducting, etc. to determine what your rough-in vs. finished ceiling height will be.

Span will determine what size your floor/ceiling joists will need to be, which in turn may dictate the direction of your installed joists in order to maximize and simplify the installation of any overhead utilities- I would guess it to be 9' minimum, 10' preferable in order to keep your finished ceiling at 8' or so.

A trolly/crane setup has crossed my mind and I’ll have to do some more research/thinking on that. It would be handy to move metal into the room.Thought about an I beam and a trolley hoist or gantry crane? Even an engine hoist, I'd make it taller than 8ft. What are you going to use the loft for? I think I'd figure the minimum height used in the loft and maximize the height on the ground floor. Maybe even consider the I beam/trolley for moving stuff upto the loft.

I plan to install a winch/elevator to lift stuff up into the loft.

I’ll likely do a good sized sliding door or maybe a double slider so I can up it up 8-10’If going with an I beam/trolley, I'd keep it up by the rafters, above the bay and loft. If you want to also access the "fab room", consider putting a ceiling/floor scuttle above the fab room, so you can open it up to use the trolley to lower things from above down into the fab room. Make the entry door(s) to the fab room large enough to accommodate an engine stand, consider a double door.

Heating shouldn’t be too big of an issue. All exterior walls are 7” thick and will have board and batten siding, 1.5” air gap, 2” foam board and then either another 3.5” airgap or 3.5” of batt insulation or blown in cellulose. I’ll have infloor heat and I’ll throw a 12k btu window unit in a window in the loft for A/C for now, with plans to install a 5-6 ton unit with duct work down the center of the shop down the road.Yeah, that's why I said finished height of 8'- so everything can be tucked in above the finished ceiling and still have 8' clearance. No hanging lights- just troffer lights in the fab room, keep your overhead open. It may not be as critical in OP's Kentucky, but up here anything over 8' is a b**ch ($$) to keep heated in the winter, same applies to cooling in the summer. All that heating and cooling money coulda paid for those new TrickFlow heads I've been eyeballing...

1WildRT

Well-Known Member

It's easier to build it tall & decide later you didn't need all that space than to add space later.... I have 10 & 12 ft materials standing in racks along one wall, moving them I use all my ceiling height...

This is my hobby shop with 10 1/2 ft. Ceiling and my 2 tallest machine tools. The mill is 7 ft. And the engraving machine is 8 ft. Pardon my mess, I’m painting the outside.

My question is how big your fab room is going to be and how are you going to ventilate it. Metal working generates smoke and sometimes quite a bit. Taller is better.

There are other options to overhead cranes, this is my big joe forklift my dad bought at auction years ago. The 12v battery died years ago. 2-3k to have it rebuilt. I have been using it with a car battery I bought at the salvage yard for $25 4 years ago. It sees alot of use.

I also have another hobby shop that is 1200 sq. Ft. 14 ft ceiling, Unheated for my car stuff. Inside that I built an assembly/work room that is insulated and heatable for winter work/hanging out in. 8x16 with 8ft. Ceiling and a loft on top. It has a home built insulated 6x7 door that slides open/closed on a trolley like a barn door would. But the intention never was to do fab work in it. I do most my welding in the main part of the building or outside.

Agreed, I build with deck screws and a screw gun just for the fact that its not permanent. I can take it apart to modify it and reuse all old materials if it suits the change. Buy good quality screws, not dry wall screws that are prone to pop the heads off.It's easier to build it tall & decide later you didn't need all that space than to add space later.... I have 10 & 12 ft materials standing in racks along one wall, moving them I use all my ceiling height...

My fab room will be 12x20.My question is how big your fab room is going to be and how are you going to ventilate it. Metal working generates smoke and sometimes quite a bit. Taller is better.

For ventilation, I could put a few exhaust fans in the ceiling, and ideally, I’d like to have one of those movable vent hood things to use over the welding table then to suck the smoke out before it house time to

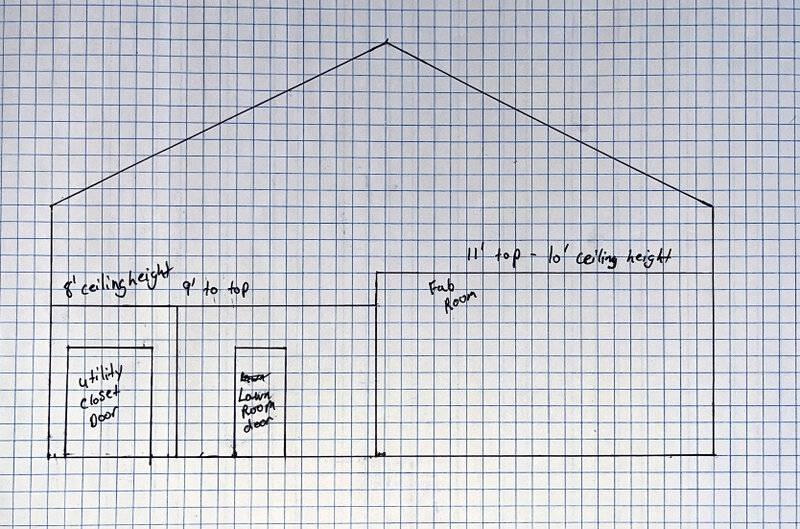

I guess there’s no reason my loft needs to be all the same height. Here’s an idea I had. Make the ceiling height in the utility closet/bathroom and lawn room 8’, which would make the loft height around 9’. Then make the fab room ceiling height 9’ or 10’ which would make the loft height over that 10’ or 11’.

Alan J Odze

AJ

if you want to ever install a lift minimum height must be 14. I have 20 foot ceiling with one lift. My lift is 12 foot.

Not true. They have lifts that are made for lower ceilings, as low as 10 feet.

-