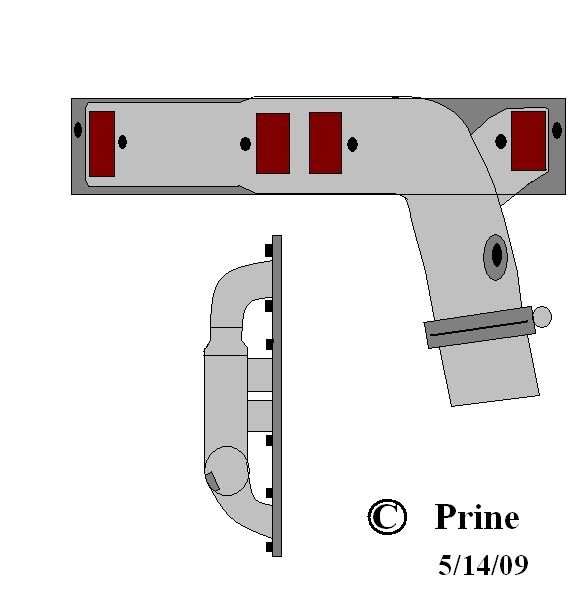

So.......last night (technically this morning) at 2:15am I awoke from a strange dream...I dreamed I was bolting up a set of headers in a Dart from above the fender....( I KNOW !!)....the headers were nice too. Thick 3/8" inch flanges, 2" Primaries, O2 sensor bungs and (1) Bolt V-Band Clamps at the collector to attach the head pipes.

I jumped out of bed and ran into the garage to draw up my idea on a piece of paper before the vision eluded me.

Well this morning (actual daylight) I went into the garage to brainstorm....I have some 2" 14ga mandrel bends, some 2.5" too.

I am aware that Harold, associated with Spitfire, makes headers for mopars' that are based on a Tri-Y design, but my idea differs in a few aspects.

I am interested in sharing my idea with the FABO community, and maybe possibly even Branding my header concept FABO Headers....

I need a guinea pig or two...that are interested in A-body Headers, with Manifold like seal, and fit...and can possibly throw some R&D investment money my way to purchase stuff like flanges, pipe bends, o2 sensor bungs, and V-band clamps....so I can do a cost analysis.

The prototype headers once completed would go on to the prospective investors, no other charges, for fitment testing and review....and after the review process to keep forever....maybe serialized as Header Set 00001/00002/00003 and so on.

I have a TiG Welder and metal working tools, and intend to weld everything with the TiG process to keep the b.b's and slag non existant.

I would like to further go on, and offer my design in both Mild Steel, and T304 Stainless also....might even go the Ceramic Coat route...if desired.

Please comment on my idea and lets kick this around.

I jumped out of bed and ran into the garage to draw up my idea on a piece of paper before the vision eluded me.

Well this morning (actual daylight) I went into the garage to brainstorm....I have some 2" 14ga mandrel bends, some 2.5" too.

I am aware that Harold, associated with Spitfire, makes headers for mopars' that are based on a Tri-Y design, but my idea differs in a few aspects.

I am interested in sharing my idea with the FABO community, and maybe possibly even Branding my header concept FABO Headers....

I need a guinea pig or two...that are interested in A-body Headers, with Manifold like seal, and fit...and can possibly throw some R&D investment money my way to purchase stuff like flanges, pipe bends, o2 sensor bungs, and V-band clamps....so I can do a cost analysis.

The prototype headers once completed would go on to the prospective investors, no other charges, for fitment testing and review....and after the review process to keep forever....maybe serialized as Header Set 00001/00002/00003 and so on.

I have a TiG Welder and metal working tools, and intend to weld everything with the TiG process to keep the b.b's and slag non existant.

I would like to further go on, and offer my design in both Mild Steel, and T304 Stainless also....might even go the Ceramic Coat route...if desired.

Please comment on my idea and lets kick this around.