JGC403

Well-Known Member

I want to figure out why it let go. No point in putting it back togeather with new gaskets and it happening again. Engine is a Magnum 360, with stroker crank, Edelbrock aluminum heads.

Cylinder #8 was filling with water.

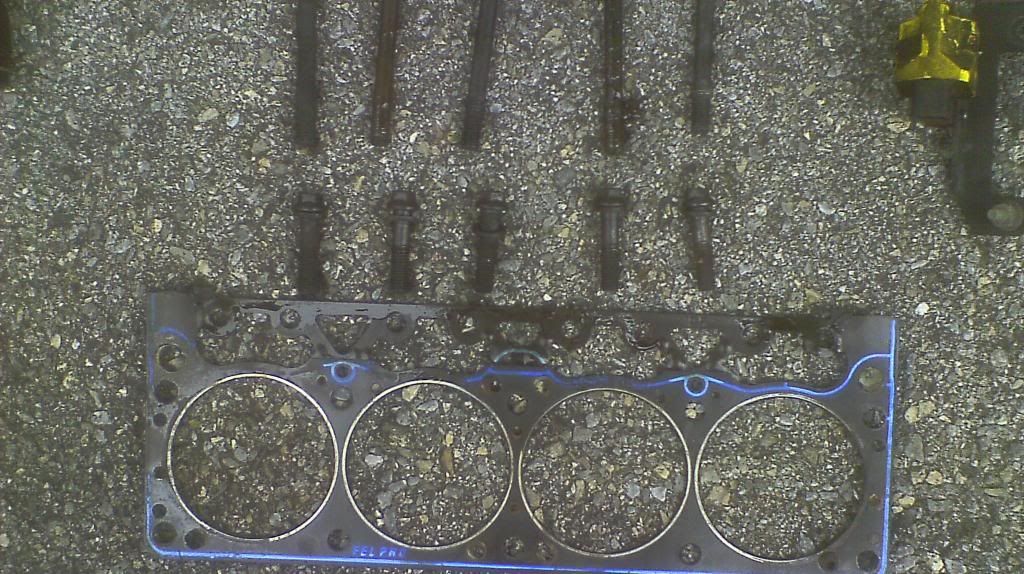

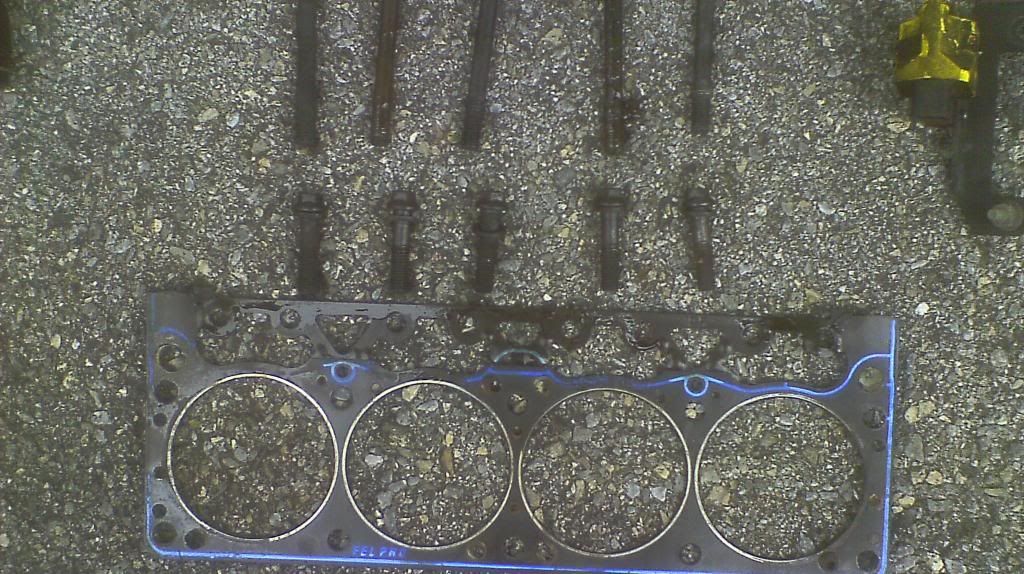

Head gasket and bolts:

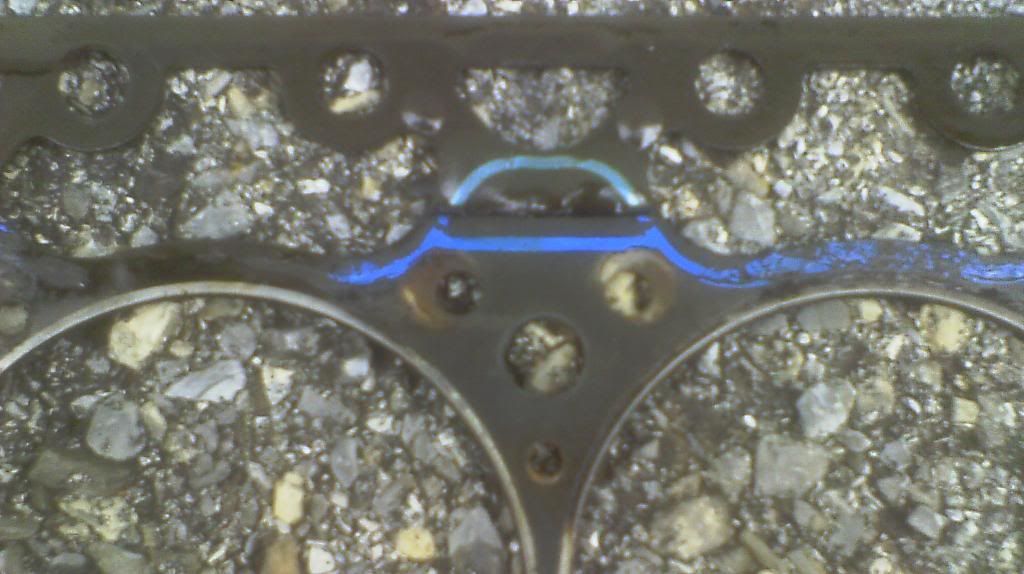

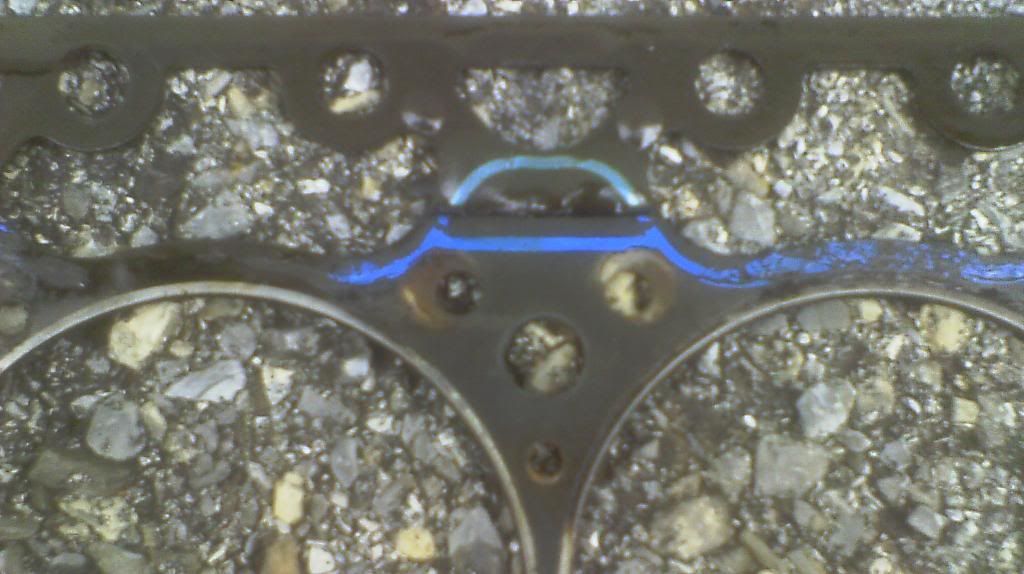

Looks like that is where it failed, part of the fire ring is MIA:

Why are the bolts so greasy:

does the missing blue line on the Fel Pro gasket mean anything, another leak?

A lot of carbon build up:

Cylinder #8 on left:

Eddy head, valves and plugs are red because of octane booster, I think.

More carbon build up along the edge of the combustion chamber on the head:

Cylinder #8 was filling with water.

Head gasket and bolts:

Looks like that is where it failed, part of the fire ring is MIA:

Why are the bolts so greasy:

does the missing blue line on the Fel Pro gasket mean anything, another leak?

A lot of carbon build up:

Cylinder #8 on left:

Eddy head, valves and plugs are red because of octane booster, I think.

More carbon build up along the edge of the combustion chamber on the head: