You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Husqvarna chainsaw questions

- Thread starter Syleng1

- Start date

-

WOW! Thank You for your service, that's a hard and dangerous line to keep.

Bill Crowell

Well-Known Member

Some threads get even better when they're hijacked.

Being a cheapskate, of course I'm using the illustrious Horrible Fright chain sharpener, but sometimes I wonder if I'm doing more harm than good!

Can somebody explain to me a foolproof way for setting the depth of the cut? How far down on the tooth should you take the wheel?

And how can you be sure that you're taking the same amount off the teeth in both directions?

Being a cheapskate, of course I'm using the illustrious Horrible Fright chain sharpener, but sometimes I wonder if I'm doing more harm than good!

Can somebody explain to me a foolproof way for setting the depth of the cut? How far down on the tooth should you take the wheel?

And how can you be sure that you're taking the same amount off the teeth in both directions?

Can somebody explain to me a foolproof way for setting the depth of the cut? How far down on the tooth should you take the wheel?

And how can you be sure that you're taking the same amount off the teeth in both directions?

The best way to tell if you have you’re rakers down far enough is your chips curl. Analyze the chips (sawdust) after cutting a piece. They should look like curly-ques. If it is fine sawdust you may need to sharpen the cutters but if the chips still aren’t curls and still sawdusty you may need to take your takers down.

As for sharpening the cutters, you want to maintain how it comes from the factory. They are all perfect when they are new so after each days work you should check them, especially if you rocked the chain (like when bucking downed logs and you go too deep and hit soil) or if you hit a nail in a tree. Inspect for bad cutter teeth and start sharpening the worst tooth. Count strokes as you sharpen. When it is satisfactory then take that same amount of licks off each following cutter. Do both sides the same (left and right cutters). It will j-cut if one side is sharper. It just won’t cut straight. There is an angled line on top of the cutter. That is a guideline so that you know what the factory angle was.

I ended up spending about 18 hours on that fire last Friday through Saturday. We got relieved yesterday afternoon and slept the rest of the day. Now it’s my off day so pics will be coming of saws and now I’m thinking about doing a tutorial for free hand sharpening for you guys. I go back to work on Wednesday.

Bill Crowell

Well-Known Member

Thanks very much for the very kind and informative reply, go-fish! I love it when you have a new chain, and the chips come off as curls. Unfortunately, I find that after the chain becomes dull I am never again able to make it cut curly chips again.

I'm getting the feeling that you experienced chainsaw guys keep your chain sharp by manual sharpening, and don't use an electric sharpener(?). I really need to improve my manual sharpening technique. Of course there are lots of youtube videos about how to sharpen a chain, but you never know if the guy really knows what he is talking about.

I'm getting the feeling that you experienced chainsaw guys keep your chain sharp by manual sharpening, and don't use an electric sharpener(?). I really need to improve my manual sharpening technique. Of course there are lots of youtube videos about how to sharpen a chain, but you never know if the guy really knows what he is talking about.

7/32” and 5/32” round files. The 5/32” is for a pruner or pole saw. The 7/32” file is what you would use for a homeowners or professional saw.

Again, I like to find a bad cutter (if I’ve hit anything like rocks or a nail in a tree) and go from there. Always take the same amount off each cutter so that all of them are wore equally or you could j-cut. J-cutting is just what it sounds like. The cut will trail to one side and not cut straight due to one side of the cutters cutting more aggressively. If you favor your left or right side the chain will tell you in the cut. It’s good to be ambidextrous when hand sharpening a chain.

Again, I like to find a bad cutter (if I’ve hit anything like rocks or a nail in a tree) and go from there. Always take the same amount off each cutter so that all of them are wore equally or you could j-cut. J-cutting is just what it sounds like. The cut will trail to one side and not cut straight due to one side of the cutters cutting more aggressively. If you favor your left or right side the chain will tell you in the cut. It’s good to be ambidextrous when hand sharpening a chain.

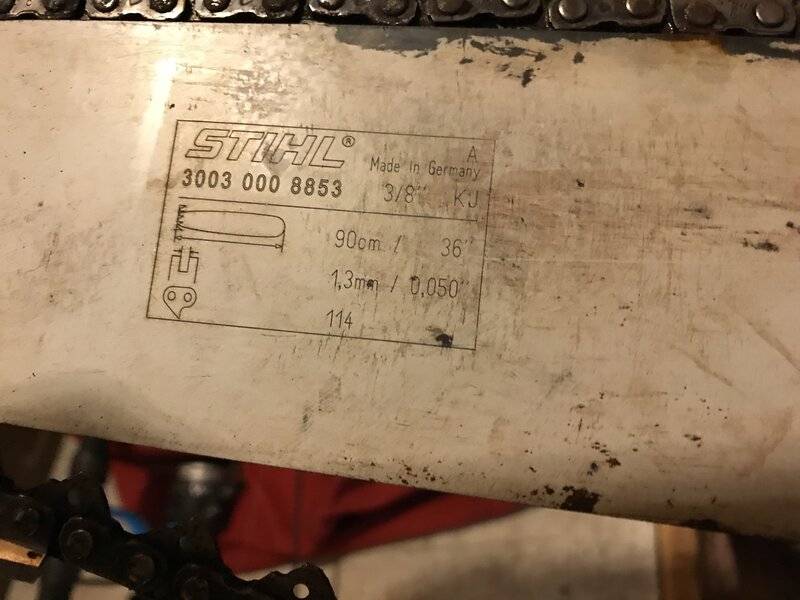

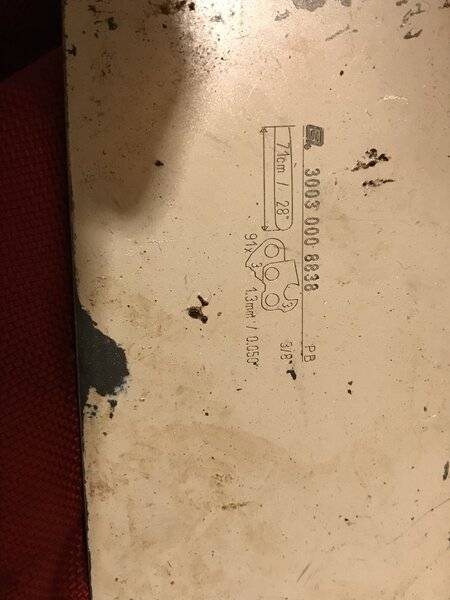

Here, stamped on the powerhead end of the bar is the chain specs. Most all bars will have this info.

One bar tells us it is a 36” bar with a .050” gauge and uses a 114 link chain. You would buy you chain with these specs as you basis. You might want a full compliment (Full Comp) of cutters or a skip based on your cutting needs. For smaller diameter or if you want to stay away from kick back you want a full comp. If your cuts call for more aggressive chain try a skip chain where there are fewer cutters. Same amount of links but fewer links with cutters. The other bars info is laid out differently but has the same type of information. It still takes a .050” gauge but is a 28” bar and uses a 91 link chain.

One bar tells us it is a 36” bar with a .050” gauge and uses a 114 link chain. You would buy you chain with these specs as you basis. You might want a full compliment (Full Comp) of cutters or a skip based on your cutting needs. For smaller diameter or if you want to stay away from kick back you want a full comp. If your cuts call for more aggressive chain try a skip chain where there are fewer cutters. Same amount of links but fewer links with cutters. The other bars info is laid out differently but has the same type of information. It still takes a .050” gauge but is a 28” bar and uses a 91 link chain.

Some of our chain. Project chain. Our good chains are on the fire engine and Hotshot buggies. When the chain gets sharpened down too far it’s retired and we use it on prescribed fire, brushing , and clearing projects.

The teardrop shaped bar is a brush bar used for, well, brush. The tip of a regular bar has a pretty tight radius and the brush bar is big and round allowing for less chain speed to be lost going around the tip. They aren’t used much anymore because you can’t cut trees with them. In our work we might be cutting brush and come across an oak with fire in the top. We can’t waste the time on the fire ground to switch out bars or call another saw over that has a regular bar on it.

One of these chains ain’t like the other! One is a full skip and one has a cutter every four links. Kickback city but cuts aggressively through big stuff. These two chains aren’t good for the inexperienced or in brush where you’re cutting 3-4” diameter or less.

The teardrop shaped bar is a brush bar used for, well, brush. The tip of a regular bar has a pretty tight radius and the brush bar is big and round allowing for less chain speed to be lost going around the tip. They aren’t used much anymore because you can’t cut trees with them. In our work we might be cutting brush and come across an oak with fire in the top. We can’t waste the time on the fire ground to switch out bars or call another saw over that has a regular bar on it.

One of these chains ain’t like the other! One is a full skip and one has a cutter every four links. Kickback city but cuts aggressively through big stuff. These two chains aren’t good for the inexperienced or in brush where you’re cutting 3-4” diameter or less.

MS 461. We use a variety of big Stihls. 440’s, 660’s ...

Sometimes it would be nice to use a lighter model but we have to be ready for the biggest of trees and don’t have the space to carry a second or third saw.

My hard hat after the last fire has retardant all over it. You know those flyboys like dropping retardant on the ground troops. They say it’s harmless, rumored to have a fertilizer in it, you shouldn’t get it in body’s of water to protect marine life. Probably carcinogenic.

Sometimes it would be nice to use a lighter model but we have to be ready for the biggest of trees and don’t have the space to carry a second or third saw.

My hard hat after the last fire has retardant all over it. You know those flyboys like dropping retardant on the ground troops. They say it’s harmless, rumored to have a fertilizer in it, you shouldn’t get it in body’s of water to protect marine life. Probably carcinogenic.

mopowers

Well-Known Member

MS 461. We use a variety of big Stihls. 440’s, 660’s ...

Sometimes it would be nice to use a lighter model but we have to be ready for the biggest of trees and don’t have the space to carry a second or third saw.

My hard hat after the last fire has retardant all over it. You know those flyboys like dropping retardant on the ground troops. They say it’s harmless, rumored to have a fertilizer in it, you shouldn’t get it in body’s of water to protect marine life. Probably carcinogenic.

View attachment 1715641268

View attachment 1715641270

That is some tough work!!! US Forest Service, I presume? What forest do you work on?

That is some tough work!!! US Forest Service, I presume? What forest do you work on?

Cleveland N.F. down in San Diego. Looks like you are near the Mendocino N.F. if you are in W. Sac. One of my favorite forests. We are still in fire season around here. A lot of Santa Ana winds this year.

mopowers

Well-Known Member

Cleveland N.F. down in San Diego. Looks like you are near the Mendocino N.F. if you are in W. Sac. One of my favorite forests. We are still in fire season around here. A lot of Santa Ana winds this year.

Awesome man! I actually worked on a type 2 hand crew out of the Mendocino during summers in college (2001-2004), then moved over to an engine on the El Dorado N.F. for a yr before switching careers all together. Good times for sure! I still find myself checking the sit report out of curiosity. Stay safe man - that line of work is no joke!

Oh, and we ran Stihl 440's on every crew I was ever on.

Last edited:

I actually worked on a type 2 hand crew out of the Mendocino during summers in college (2001-2004), then moved over to an engine

You understand the struggle! It’s a rewarding job but just not rewarding in dollars.

-

Similar threads

- Replies

- 21

- Views

- 2K

- Replies

- 63

- Views

- 2K

- Replies

- 91

- Views

- 7K