mopowers

Well-Known Member

Minor update - I finished cleaning up the inner quarters where I scrapped the factory sound deadener and also got the battery tray and holdown done.

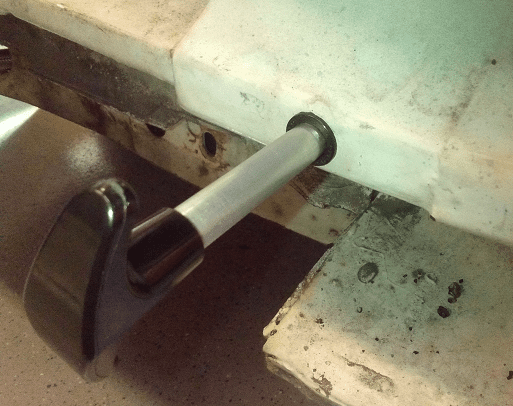

I found this slick little plastic grommet to trim out where the kill switch rod enters the trunk.

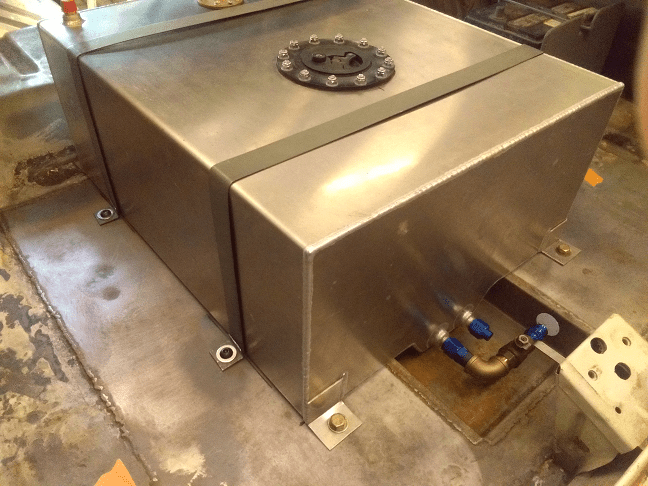

I also made up some steel fuel cell straps because I didn't feel comfortable with the thin factory aluminum tabs holding the cell containing up to 20 gallons for gasoline. I do have some felt strips that I'll be using as padding between the straps and the aluminum cell as well.

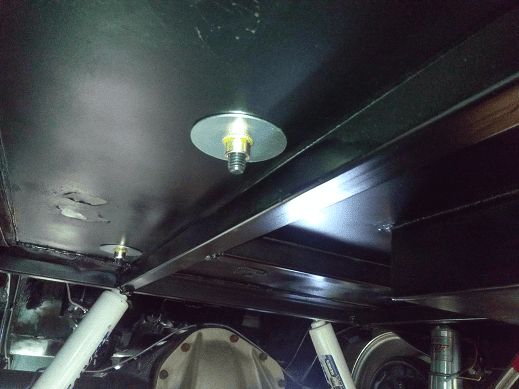

I didn't feel like welding tabs to the truck pan frame work so I just used 5/16" rivnuts and fender washers to spread the load. I think that'll be good enough, along with the other 4 bolts going through the 1"x1" square tubing floor frame.

I found this slick little plastic grommet to trim out where the kill switch rod enters the trunk.

I also made up some steel fuel cell straps because I didn't feel comfortable with the thin factory aluminum tabs holding the cell containing up to 20 gallons for gasoline. I do have some felt strips that I'll be using as padding between the straps and the aluminum cell as well.

I didn't feel like welding tabs to the truck pan frame work so I just used 5/16" rivnuts and fender washers to spread the load. I think that'll be good enough, along with the other 4 bolts going through the 1"x1" square tubing floor frame.