I dunno whats up with the pics, I didn't move them... I'll see if I cover everyone; The wheels and tires are 15 X 15 Centerline Convo Pro rear, 15 X 4 fronts. Rear tires are M/T Sportsman Pro's, 29 X 18.5's. The coilover conversion is from Magnum Force. Ramcharger, thanks for clearing up the double shear thing. I don't think I have enough money to build anything stout enough to shear off my cheesy setup. The way you describe is a stronger sounding design. The car sat in the weeds for 12 years, so I have alot of work ahead of me. Thanks for the good comments.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

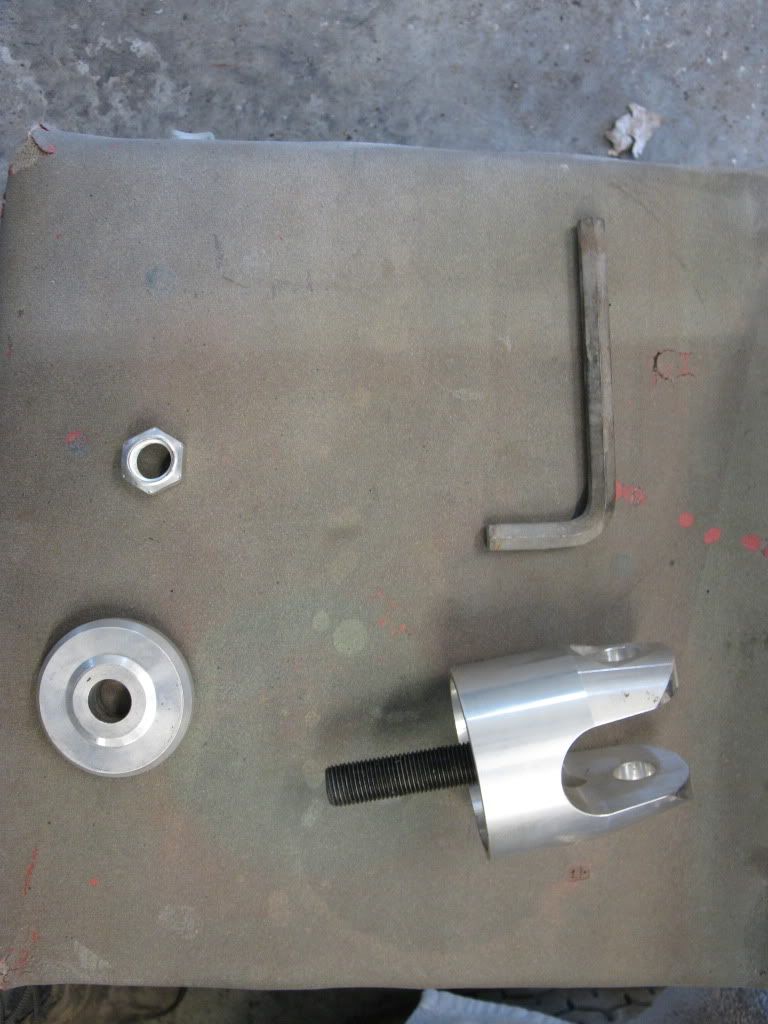

Motor plate + coilover conversion = too easy

- Thread starter BBBCUDA

- Start date

-

Who's coil over set up is that?

Please share with us.

That looks pretty f-ing good! Hurry up already!

You know how slow I am... :bootysha:

According to their website it looks like $600 for the coil over conversion +$300 for the upper controls arms and so on.

ramcharger

Dismember

I dunno whats up with the pics, I didn't move them... I'll see if I cover everyone; The wheels and tires are 15 X 15 Centerline Convo Pro rear, 15 X 4 fronts. Rear tires are M/T Sportsman Pro's, 29 X 18.5's. The coilover conversion is from Magnum Force. Ramcharger, thanks for clearing up the double shear thing. I don't think I have enough money to build anything stout enough to shear off my cheesy setup. The way you describe is a stronger sounding design. The car sat in the weeds for 12 years, so I have alot of work ahead of me. Thanks for the good comments.

I didn't mean to imply that your set-up was weak or would cause problem, I was just wondering how you did it.

Sorry, I must have been typing when you posted. On my motor plate I only have a one tab behind it on each side.

Thank you! Any issues at all?

Ramcharger, no offence taken, and I didn't mean to be a wiseguy. I did kinda mean it though, the single tab is the "cheesy" way to do it over the way you mentioned, but I have seen some very fast cars done with the single tab. Setting an engine right down in a 1/4" gap between 2 plates doesn't sound like fun to me... The guys plate I used to template the ears on my plate had been running the single tab version on a 10 second '71 Challenger for years. I am comfortable with it, but it can be made stronger.

blasphemous

Well-Known Member

I don't think sitting a motor plate in that gap would be fun either. I'd imagine that you could angle the top outwards, add like a 1/2" and bend it maybe 30* to guide the plate it. Car looks awesome as it sits though!

ramcharger

Dismember

Only bolts that I have to watch are the ones on the water pump where it is mounted to the plate. I have an electric pump.

Thanks Jeff!

Ramcharger, no offence taken, and I didn't mean to be a wiseguy. I did kinda mean it though, the single tab is the "cheesy" way to do it over the way you mentioned, but I have seen some very fast cars done with the single tab. Setting an engine right down in a 1/4" gap between 2 plates doesn't sound like fun to me... The guys plate I used to template the ears on my plate had been running the single tab version on a 10 second '71 Challenger for years. I am comfortable with it, but it can be made stronger.

Thank you BB!

I don't think sitting a motor plate in that gap would be fun either. I'd imagine that you could angle the top outwards, add like a 1/2" and bend it maybe 30* to guide the plate it. Car looks awesome as it sits though!

It may be more hassle than it's worth. once I get my block back I'll play around with the idea. Not being able to move the engine fore/aft and the fact that engine would have to be at a pre-determined angle from front to rear may also make it impossible to do.

I did and an adjustable link with rods ends on it to keep the motor from rocking back and forth.

You might want to change out the front pump seal and the tail housing seal since it's been sitting so long.

You might want to change out the front pump seal and the tail housing seal since it's been sitting so long.

Probably a good idea! I can't wait to see how this converter works. It will probably be a dog, but between the converter and 4.88's, it should at least leave well!I did and an adjustable link with rods ends on it to keep the motor from rocking back and forth.

You might want to change out the front pump seal and the tail housing seal since it's been sitting so long.

Customrust

Member

You really went texas chainsaw massacre on that trans. It's so nice now you almost have to paint it. Leatherface!

You really went texas chainsaw massacre on that trans. It's so nice now you almost have to paint it. Leatherface!

Yeah, I probably should have used something finer than a 40 grit disc, but I guess it's better than nothing. You can only see about 1 inch of the bellhousing area anyways.

Customrust

Member

Did you manage to get it down the track?!

Did you manage to get it down the track?!

Up till 2 a.m. last Sunday. Went home, got 3 hrs. sleep, went back and worked on it until 11 a.m. loaded it up, made it to tech with 1 minute to spare, and it passed! (Thats the end of the good news)... Leaving the pits, it sounded very rough, and wouldn't register over 2,000 Rpms. on the tach. I took a guess that it was the Orange box for the ignition. I begged another box off another racer, and as soon as it was on, wow! major difference... for about 100 feet. It cooked the second box. Loaded it back up, and went home.

I wired it to the wrong side of the ballast... That apprently isn't good. I fixed that, then found the 1983 vintage alternator wasn't charging. New alternator, now I have almost 17 volts back at the battery... New voltage regulator, all better. New chrome ignition box, off to the track. I get there at 9:30, dry and the suns coming out, 50 other guys there too. A big TRACK CLOSED sign, with no explanation. CRAP!

I hope to try again tomorrow. I did take it for a no plates, open header blast down the road. I hope it hooks better at the track, it boils the 29 X 18.5's much worse than I was expecting.

Track open today, went down, they were still drying the track. The place was mobbed, lots of cars. I waited an hour or so, it sprinkled for about 20 minutes and they called it a day... Just about as soon as they called it, the sun came out, the wind died to nothing, and it was a beautiful day. CRAP. They did say to hold onto your wrist band, it will be good for next Saturday, the LAST day of the season.

blasphemous

Well-Known Member

Doesn't sound like you're having much luck in the end there. At least it is coming along though.

I didn't mean to imply that your set-up was weak or would cause problem, I was just wondering how you did it. A double shear mounting may complicate engine installation as the engine plate would have to be dropped in right between all 4 tabs which could be a pain in the rear.

I have mine setup in double shear. I welded the rear tab to the frame rail. The front ones are removable. They have a long 3/8" bolt going all the way through the frame rail. On the bottom side I use 1/8" plate to keep from crushing the frame rail when I tighten it up.

Makes engine installation a breeze.

To the original poster, do you know what spring rate your coil overs are setup with?

I have mine setup in double shear. I welded the rear tab to the frame rail. The front ones are removable. They have a long 3/8" bolt going all the way through the frame rail. On the bottom side I use 1/8" plate to keep from crushing the frame rail when I tighten it up.

Makes engine installation a breeze.

To the original poster, do you know what spring rate your coil overs are setup with?

I will see if I can find the origional box, as I beleive the rate was written on the side. If I find it, I will let you know.

Customrust

Member

Woah. You must have been up pretty early today. Everything setup and gone before 8:45! Thanks! I hope you have better luck this weekend. When you get it all set up I want a ride in that wheelstander. Nov 7th is our next match up north, I've got everything loaded up and ready to go! No excuses you already told me how much you don't like sleeping!

earthmover

in the tire smoke

what happen to the pics

what happen to the pics

Dunno with the pics, and I'm not sure how to replace them either without starting the thread over.

I finally made it to the track, and it was mobbed with people, prolly 500 cars. I was still in tech when they called test and tune, so I got to check NOTHING. I was super nervous, but managed a decent, high gear burnout with the Sportsmans at 10 Psi. The launch felt OK, but I had people watching who said it spun pretty badly. 60 ft. of 1.7, not great. within 60 feet, it started backfiring, and continued for the length of the track. After some searching, MOST of the problem was found: The cell was empty. :angry7:

Put in fuel, lowered tires to 8 Psi, good burnout, major loading and unloading of the suspension, really ugly, 1.8 60 ft. ET of 13.1 @ 103. UGLY. The car broke up at just over 5,000 rpms, and with 4.86 gears, I was limping over the line.

Pulled a little timing, guessing maybe too much, (not). Left at 3,000 and very gently rolled into it, ugly 60 ft. of 1.8 again, still did not want to pull over 5,000 rpms, popped at the top of 1st, second, and drive, ran a 12.8 @ 102 skipping for the last 300 feet. Out of track time. Not at all what I wanted, but at least I made it. I think it is starving for fuel, and going lean on the top of each gear. Bummer is, the season is OVER.

-

Similar threads

- Replies

- 25

- Views

- 2K

- Replies

- 1

- Views

- 542