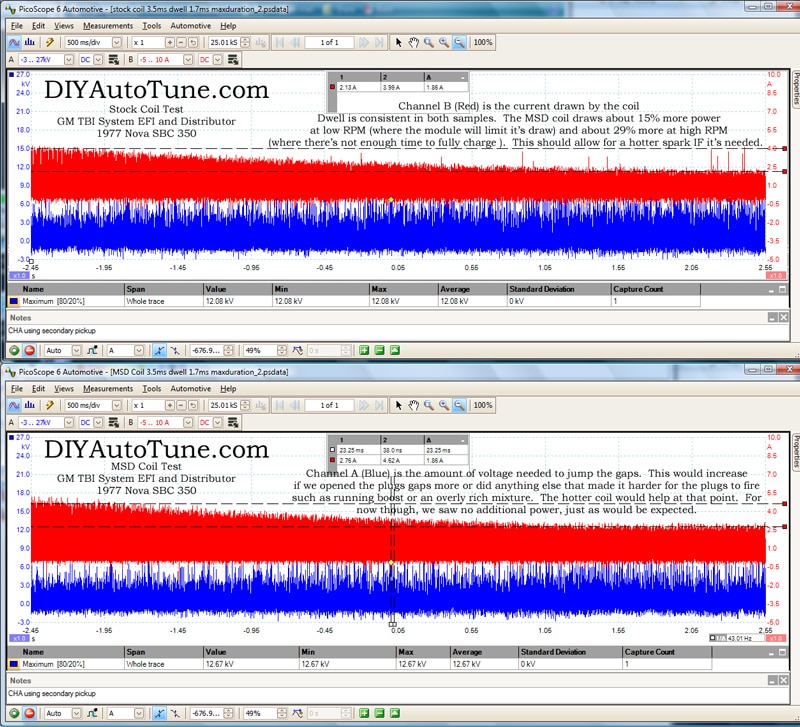

My boss once did a test on a GM coil vs an MSD coil and in that particular case, the results were a bit different. We monitored both the coil current draw and the secondary voltage. This test was done with a variable dwell angle HEI module, so you would get a different curve with a Mopar system, but I'd expect the same trend.

I would not expect the same results as the HEI ignition as they are two different animals. No varible dwell with the Mopar box and a good HEI module can handle a coil draw of over 5.5 amps of current, Even exceeding 7 amps with an aftermarket HEI module. Also, there is no ballast resistor used.

The MSD coil drew more current across the board. So this coil would give you more spark energy at idle and at the top end. However, this engine didn't really like to rev out very well, didn't make a lot of cylinder pressure, and so it didn't really have any need for a hotter ignition system. I don't expect any problems with the coil upgrade here, but whether you will benefit depends on what mods you have.

Again, we have apples and oranges here. A MSD HEI coil can't be compared to a Blaster II and a Mopar orange box with a ballast resistor delivering only 9V on the primary. A coil can't draw any more then an inductive Mopar ECU can handle.

The voltage is definitely one of the key reasons the boxes use a different coil. However, it's the box, not the coil, that underperforms at low RPM. A CDI box's spark does not burn as long as a stock ignition, so it compensates by adding more of them.

I agree that an inductive style ignition has a longer duration spark than a CDI, but I wonder if your statement holds true in regards to the box vs the coil. If it did, it would be much more apparent at high rpm vs. low rpm, yet the multiple spark is discharged only below 3K. Mallory even rates their coils on expected rpm use.

Good point, oil filled MSD coils should never be installed sideways. I've seen one self destruct when installed upside down and the oil leaked out.