standup303

Well-Known Member

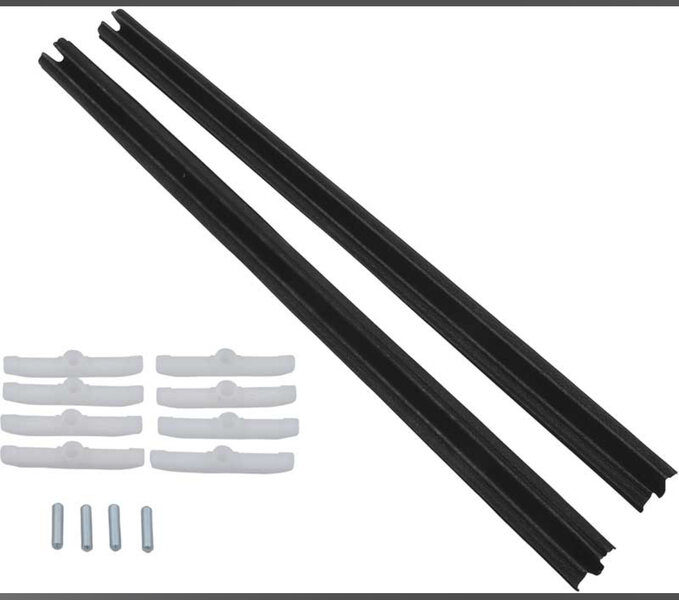

Just got some new felt and tabs for the front of the door glass run channel. From what I’ve reached looks like I need to:

-Pop the door glass out the top

-Take the entire window channel with the vent glass out the top

-Cut some holes for the tabs in the new felt/plastic

-Trim the top side of the plastic to fit the vent window rubber

-Looks like some people had issues with the new felt being too tight and have to trim it?

Is that about it? Any tips? Going to attempt it this weekend. Below is the part I’m talking about.

https://www.classicindustries.com/product/1969/dodge/dart/parts/mn3104.html

-Pop the door glass out the top

-Take the entire window channel with the vent glass out the top

-Cut some holes for the tabs in the new felt/plastic

-Trim the top side of the plastic to fit the vent window rubber

-Looks like some people had issues with the new felt being too tight and have to trim it?

Is that about it? Any tips? Going to attempt it this weekend. Below is the part I’m talking about.

https://www.classicindustries.com/product/1969/dodge/dart/parts/mn3104.html