I'm not sure what compressor you may have but on Quincy compressors (and many others I have worked on) the bottom of the cylinder has a 45 degree taper. No ring compressor is necessary if you have that design. You simply invert the cylinder so the bottom is up and take the piston with the connecting rod and position it in the taper. Be sure to oil it well and you simply use you fingers to assist the rings in compressing as you gently wiggle and push the piston in.

This was only necessary on cylinders where the connecting rod bearing was wider than the diameter of the cylinder (usually the high pressure piston). If the rod bearing is smaller than the cylinder diameter (low pressure typically) then it could be installed from the top using an automotive ring compressor, but if the cylinder was removed, then it is probably easier to just use the taper on the bottom of the cylinder bore.

I hope this helps, I realize not all compressors are built the same. I used to train our mechanics at the nuclear plants we operated in overhauling our compressors and most of them were this way.

Be sure to look at the rings as some will have a top side which is usually denoted with a small dimple or "pip" as Quincy calls it. If you are not sure which way they go (if the rings are not of a symetrical cross section) look up a service manual for your compressor.

Hope this helps.

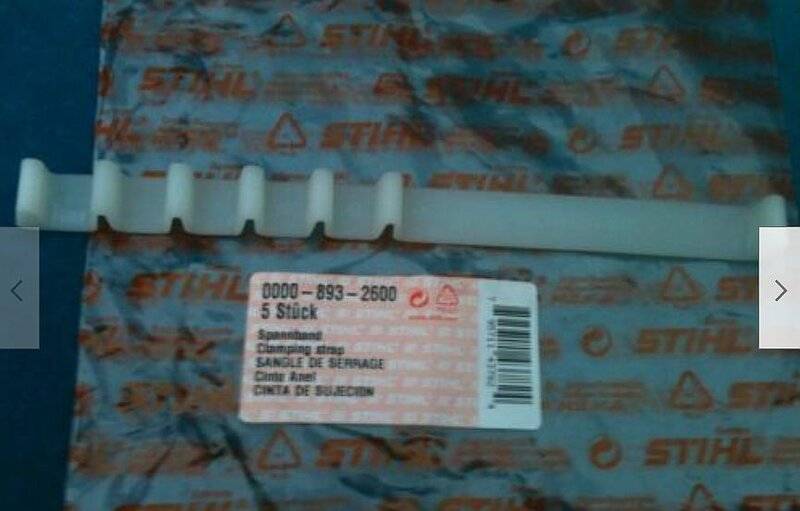

Reference only...check YOUR manual, but this is what I'm talking about with the rings

This is the only pic I could find on the internet showing the piston installation...not very good I know. If you look carefully at the larger low pressure piston to cylinder area you will notice the dark band...that is the taper that assist in the ring compression.