Can the oil pan on a 360 in a 70 Duster be pulled without lifting the engine, or pulling the engine out completely? Want to put a deeper pan on, but if the motor has to lift out then I won’t bother for now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pulling oil pan

- Thread starter gumper

- Start date

-

Alaskan_TA

Well-Known Member

Possible, yes.

You would have to lower the steering link down & move it out of the way though.

No real need for more oil though.....

You would have to lower the steering link down & move it out of the way though.

No real need for more oil though.....

I’ll take the steering link off. My motor is running low on oil pressure at higher RPMs on the track with a high volume pump and the stock pan. Thought about just dumping an extra quart in the pan, but not sure if that’ll fix it. Either the pickup is too close to the pan, or oil isn’t getting back to the sump fast enough. Either way I don’t want to trash my 410 due to low oil.Possible, yes.

You would have to lower the steering link down & move it out of the way though.

No real need for more oil though.....

Well, that’s a long story. I didn’t put the engine together. I didn’t know it was in there until the car made some passes. The guy who did took it upon himself to do that, and I’ve expressed my concern over the issue. I’d like to put the old pump on, but of course the pan has to come off. Couple that pump with the Hughes cool face lifters that have oiling holes in the bottom, and my pressure drops to 20-25# at 6000 rpm. That’s running 15w-50 oil. As much as I’d love to just run it, I’m afraid of scattering the engine on the track at high speed.What rpm you shifting? No volume pump and stock pan don’t wok too well.

Yes problems losing pressure like that. Well the pan comes off OK but if you put a deeper pan on I’m not sure it will fit without lifting the engine.

You are Racing so you have headers also? That can make it tighter with an aftermarket pan.

You are Racing so you have headers also? That can make it tighter with an aftermarket pan.

Yeah just some junky 1 5/8 Hookers. Was looking at the Kevco M302 pan. Deeper with some baffles, but not wider.Yes problems losing pressure like that. Well the pan comes off OK but if you put a deeper pan on I’m not sure it will fit without lifting the engine.

You are Racing so you have headers also? That can make it tighter with an aftermarket pan.

I’ll be certain to have a conversation with the engine builder. He won’t be doing the next one.That’s too bad. Should be easy to find where it came from.

yellow rose

Overnight Sensation

Check the thrust. I’m betting it’s toast. I doubt that’s the engine builders fault. Of course, that is a WAG at this point.

It only has 30ish passes on it. There’s a long list of things he had screwed up when redoing this engine, so I have no doubt it was an assembly issue.Check the thrust. I’m betting it’s toast. I doubt that’s the engine builders fault. Of course, that is a WAG at this point.

yellow rose

Overnight Sensation

It only has 30ish passes on it. There’s a long list of things he had screwed up when redoing this engine, so I have no doubt it was an assembly issue.

I’ve seen thrust bearings go in 5 minutes. Only takes a few minutes to check for that.

It may be that. The motor still has to come out due to the oil pressure issue. I’m going to have to look at all the bearings and clean the debris out of the system.I’ve seen thrust bearings go in 5 minutes. Only takes a few minutes to check for that.

A deeper pan allows you to run a lower oil level. Benefits: less windage, more hp. I do get the impression from reading your past posts that performance is probably not that important to you. It may be important to the OP though.Possible, yes.

You would have to lower the steering link down & move it out of the way though.

No real need for more oil though.....

On mine I dropped the steering linkage, took the motor mounts loose and raised the engine. Came out easy after that.

Ouch, sorry to see this, glad it didn’t scatter. Aftermarket rods, are they china parts that were not to correct size? Looks like Crank is aftermarket? These aftermarket parts need to be blueprinted before use to be safe.

how does 4-8 look? How are the mains?

how does 4-8 look? How are the mains?

yellow rose

Overnight Sensation

Crank and rods are junk. The line bore needs to be done again. Clearances were off to begin with. Engine builder and his machine shop f***ed me last year. Scrap it and start over.

I’ll buy the crank and rods from you. How much do you want???

Sorry to see that.

Thanks for all the good pictures showing for the rest of us.

Sure you are bumming. Softer copper bearing insert material can transfer to the harder crankshaft making it look lots worse than it is.

Have to try a light polish on one of those crank journals to see if you can remove that transfer material and leave a smoorh crank behind.

Worth a look . . .

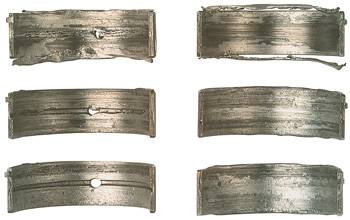

My backyard operation, was able to clean up the bearing insert transfer on this crank here on this low oil pressure stock 360. Bearings did their job and took the hit protecting the main parts. Polished by hand.

Good Luck.

Don't get too frustrated, things happen.

Thanks for all the good pictures showing for the rest of us.

Sure you are bumming. Softer copper bearing insert material can transfer to the harder crankshaft making it look lots worse than it is.

Have to try a light polish on one of those crank journals to see if you can remove that transfer material and leave a smoorh crank behind.

Worth a look . . .

My backyard operation, was able to clean up the bearing insert transfer on this crank here on this low oil pressure stock 360. Bearings did their job and took the hit protecting the main parts. Polished by hand.

Good Luck.

Don't get too frustrated, things happen.

Wow, that turned out nice. KimSorry to see that.

Thanks for all the good pictures showing for the rest of us.

Sure you are bumming. Softer copper bearing insert material can transfer to the harder crankshaft making it look lots worse than it is.

Have to try a light polish on one of those crank journals to see if you can remove that transfer material and leave a smoorh crank behind.

Worth a look . . .

My backyard operation, was able to clean up the bearing insert transfer on this crank here on this low oil pressure stock 360. Bearings did their job and took the hit protecting the main parts. Polished by hand.

View attachment 1715723957

View attachment 1715723958

Good Luck.

Don't get too frustrated, things happen.

Jax340Dart

Well-Known Member

Dang,,, thats a great job you did there George

^^^^^

Hand Polishing of the Crankshaft:

320 grit emery cloth with WD-40 for lube, then follow up with the Red Scotch Brite Pads and WD-40, then if you really want to shine them up, follow up with some 1000 grit Crocus Cloth with WD-40 for lube.

Works for me . . .

Have done the Vinegar Overnight Dunk and the Hand Polishing on other crankshafts here too. Cleans them up nice.

Hand Polishing of the Crankshaft:

320 grit emery cloth with WD-40 for lube, then follow up with the Red Scotch Brite Pads and WD-40, then if you really want to shine them up, follow up with some 1000 grit Crocus Cloth with WD-40 for lube.

Works for me . . .

Have done the Vinegar Overnight Dunk and the Hand Polishing on other crankshafts here too. Cleans them up nice.

I’ll have to get back to you on that. It’s a Scat forged crank that was ground .010 once, Scat 60 6.123” rods. I also have a set of the same rods with forged 9.8:1 pistons hooked to them that I pulled out of the motor last year.I’ll buy the crank and rods from you. How much do you want???

Here are the main bearings that came out of this low oil pressure 360, and yet was still able to save the crankshaft after hand polishing, and new bearings.

-