Is it normal to run the Bilstein A-body front shocks without dust covers? They weren't provided. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question on Bilstein shocks

- Thread starter mvh

- Start date

-

One more thing: the upper bushing on the rear shocks have a 5/8" opening. The stud on the car is 11/16". I am going to have to drill out the bushings.

SKU: BIL7056065

SKU: BIL7056065

The KYBs I had didn't have them so I don't see why it would be a problem.Is it normal to run the Bilstein A-body front shocks without dust covers? They weren't provided. Thanks.

MH, i've installed and run both ways and not noticed much in the way of longevity (and one customer is especially difficult on his ride) so i say knock 'em on and ship it.

out back i just reamed the bush then it was on to lube, pressure and angle of attack for install.

out back i just reamed the bush then it was on to lube, pressure and angle of attack for install.

My KYBs have dust boots. I'm talking about the upper section that telescopes down over the actual shock tube. The Bilsteins just have a bare shaft. The instructions say you should reuse your existing dust boot, which of course I don't have.The KYBs I had didn't have them so I don't see why it would be a problem.

How do you ream out the bushing when nobody makes an 11/16 twist drill bit? I just went to Lowe's and they apparently don't exist.

Correction: Lowe's website shows 7 different brands, but Lowe's local store has zero in stock. Maddening.

Correction: Lowe's website shows 7 different brands, but Lowe's local store has zero in stock. Maddening.

jokes on you, i used a metric reamer!How do you ream out the bushing when nobody makes an 11/16 twist drill bit? I just went to Lowe's and they apparently don't exist.

Correction: Lowe's website shows 7 different brands, but Lowe's local store has zero in stock. Maddening.

Now you're going to make me do arithmetic... sheesh...

McMaster-Carr has most everything. Shipped to your door next day.How do you ream out the bushing when nobody makes an 11/16 twist drill bit? I just went to Lowe's and they apparently don't exist.

Correction: Lowe's website shows 7 different brands, but Lowe's local store has zero in stock. Maddening.

Yeah, I know, a lot of people could get it by Tuesday, but it's just weird. Everybody's website shows 11/16 drills, but not a single store actually stocks them. Why? They have every other size from 1/32 to 3/4 at every retail outlet. How much rack space are they saving by excluding ONE size? And why is it a unanimous decision to omit 11/16 by every hardware chain? Friggin' monopolies...

The crux of it is that I won't be able to install the shocks until next weekend.

The OTHER question is why PST and Bilstein don't know the proper size for the bushings. They should be the same on top and bottom. What kind of vehicle would have a smaller stud on the top (chassis) end than the bottom (spring plate) end? That doesn't make sense (so it's probably something Ford did).

The crux of it is that I won't be able to install the shocks until next weekend.

The OTHER question is why PST and Bilstein don't know the proper size for the bushings. They should be the same on top and bottom. What kind of vehicle would have a smaller stud on the top (chassis) end than the bottom (spring plate) end? That doesn't make sense (so it's probably something Ford did).

That's not so difficult for those of us who have dealt with it for unmpteen years. Conversion factor from inch to millimeters is 25.4Now you're going to make me do arithmetic... sheesh...

11/16" = .6875 = 17.46mm which will still be a tough find.

17mm = .6693 , (divided by 25.4 to get that). Could be close enough for rubber bushing versus a twist drill.

18mm is more over the 11/16" at about .708" . A tad tight or a tad loose are the metric options.

17mm Drill Bit High Speed Steel Shank Twist Drill For Wood Copper Plastic Alumin | eBay

Thanks, but I was being facetious (I've known junkyardhero for a long time)... sorry. I already did all of that math, and I decided that neither metric option was close enough for the stiff poly bushings in the Bilsteins (too small = I could never force it on given lack of leverage up there behind the axle; too large = too sloppy). Besides, I don't have any metric drill bits right now and I don't see any reason to start collecting them. I ordered an 11/16 from the local Ace Hardware for pick up Thursday.That's not so difficult for those of us who have dealt with it for unmpteen years. Conversion factor from inch to millimeters is 25.4

11/16" = .6875 = 17.46mm which will still be a tough find.

17mm = .6693 , (divided by 25.4 to get that). Could be close enough for rubber bushing versus a twist drill.

18mm is more over the 11/16" at about .708" . A tad tight or a tad loose are the metric options.

17mm Drill Bit High Speed Steel Shank Twist Drill For Wood Copper Plastic Alumin | eBay

a long, long, loooonnnngggg time.Thanks, but I was being facetious (I've known junkyardhero for a long time)... sorry.

also, i was kinda, sorta busting Max's chops a little because sometimes he over analyzes a specific task that isn't all that critical. but, he was on the ball here, the right drill for the bushings will make the job done right.

btw, freeze the bushings first, they'll drill easier.

Thanks for that tip — I know I read that somewhere once upon a time, but I had forgotten all about it.btw, freeze the bushings first, they'll drill easier.

following - hoping for a source for bellows that can be installed after installation - seems like a good way to protect some pricey shocks

1WildRT

Well-Known Member

Bilstein E4-SR1-Z012A01 Bilstein Shock Boots | Summit Racing

Free Shipping - Bilstein Shock Boots with qualifying orders of $109. Shop Shock Boots and Bellows at Summit Racing.

if you're trying to do it after the fact, it'll just be a half *** job. best way is to buy some bellows and yank the shocks and do it correct.following - hoping for a source for bellows that can be installed after installation - seems like a good way to protect some pricey shocks

Oh, great. Why doesn't PST offer these? And have them linked to the shock listings? That would have been handy.

I noticed early on that even a lot of open end wrench sets skip 11/16.

That's particularly frustrating when Mopar uses that size for a LOT of stuff.

I guess the real question is- are you ever gonna run different shocks than Billstiens?

Easy to make a hole larger.

Not so easy to make it smaller.

That's particularly frustrating when Mopar uses that size for a LOT of stuff.

I guess the real question is- are you ever gonna run different shocks than Billstiens?

Easy to make a hole larger.

Not so easy to make it smaller.

Well, the bushing is part of the shock, not part of the Mopar. So it doesn't matter if I mod it. I'll never swap them to a different vehicle with a different stud size, at any rate.

I installed the Bilstein shocks over the weekend. It all worked out in the end, but here is my summary of the modifications and workarounds I found necessary.

1. The upper bushings on the rear shocks had 5/8" holes. I had to drill them out to 11/16". I have to say, the brand new 11/16 bit cut through them like butter.

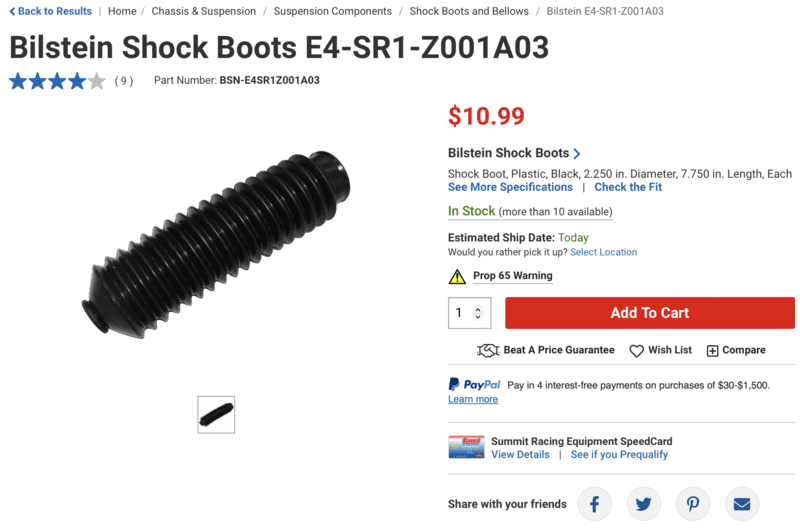

2. The front shocks had no dust boots. I didn't like that, so I bought these accordion-style boots from Summit. I was afraid the blue plastic ones that 1WildRT posted above were so large in diameter that they might scrape on the upper arms. Plus I wanted black, not blue.

3. The rubber bushings for the upper end of the front shocks have little nubs that are supposed to center the bushings on the holes in the inner fender. The supplied bushings had a nub that was only about 3/8" in diameter — much smaller than the nub in the old bushings. The hole is more like 3/4" inch, so these would allow the bushing to shift around in the hole. I reused the old bushings, which were perfectly intact, though a little hard. I used the new washers, because shiny.

4. The nut on the top end of the new shocks was metric 17mm. This just irks me because I don't carry any metric tools in my car. It also irked me because it was a nyloc nut, which meant it had to be run down the entire 1" plus of thread using a box wrench while holding the tip of the shaft from rotating with another wrench. I didn't have time for that nonsense, so I went to Lowe's and bought some regular metric 10 x 1.5 nuts, and torqued these down to spec, then ran the nylocs down on top of them for safety. On my old shocks, I had used a regular nut and a jam nut. IMO you should never use nyloc nuts in a situation that calls for a torque spec.

Hope this helps someone with their future installation.

1. The upper bushings on the rear shocks had 5/8" holes. I had to drill them out to 11/16". I have to say, the brand new 11/16 bit cut through them like butter.

2. The front shocks had no dust boots. I didn't like that, so I bought these accordion-style boots from Summit. I was afraid the blue plastic ones that 1WildRT posted above were so large in diameter that they might scrape on the upper arms. Plus I wanted black, not blue.

3. The rubber bushings for the upper end of the front shocks have little nubs that are supposed to center the bushings on the holes in the inner fender. The supplied bushings had a nub that was only about 3/8" in diameter — much smaller than the nub in the old bushings. The hole is more like 3/4" inch, so these would allow the bushing to shift around in the hole. I reused the old bushings, which were perfectly intact, though a little hard. I used the new washers, because shiny.

4. The nut on the top end of the new shocks was metric 17mm. This just irks me because I don't carry any metric tools in my car. It also irked me because it was a nyloc nut, which meant it had to be run down the entire 1" plus of thread using a box wrench while holding the tip of the shaft from rotating with another wrench. I didn't have time for that nonsense, so I went to Lowe's and bought some regular metric 10 x 1.5 nuts, and torqued these down to spec, then ran the nylocs down on top of them for safety. On my old shocks, I had used a regular nut and a jam nut. IMO you should never use nyloc nuts in a situation that calls for a torque spec.

Hope this helps someone with their future installation.

Oh, while I was in there, I noticed the rebound bumpers for the UCA were all cracked. Luckily, I had a pair of new Energy Suspension poly bumpers on hand. But then I realized why I hadn't installed them on the other Barracuda — they were about 5/16" taller than the old ones. Why, I don't know. But since this 'cuda is lowered in front, I knew I didn't want taller bumpers, so I got out the hacksaw and shortened them. Another peeve: the factory bumpers have a square head on the threaded shaft (like a carriage bolt) so they don't spin while you tighten the nut — the new ones did not. I solved that by raising the car on the jack enough to pin them in place.

I also discovered that one of the LCA bumpers was really torn up. I did not have any replacements for these, so I ordered a pair. They are easy to replace without having to take anything else apart, fortunately.

I also discovered that one of the LCA bumpers was really torn up. I did not have any replacements for these, so I ordered a pair. They are easy to replace without having to take anything else apart, fortunately.

Final word: On another thread, I managed to find out the story about the upper bushing diameter.

The correct Bilstein shocks for Mopar A-body are the following:

Front Shocks

Part number: 55-R082

10.5” collapsed height

15.75” extended height

Rear shocks

Part number: 55-R092

14” collapsed height

22.7” extended height

For some reason, PST supplies 55-R093 for the rear, instead.

55-R093 has the same exact specs (Collapsed/Extended length) as the R092 but the eyelets/bushings are different diameter (upper eye is 5/8" instead of 11/16"). This is why I had to drill out the upper bushing.

If any PST people are following this thread, I hope you can correct your listing.

The correct Bilstein shocks for Mopar A-body are the following:

Front Shocks

Part number: 55-R082

10.5” collapsed height

15.75” extended height

Rear shocks

Part number: 55-R092

14” collapsed height

22.7” extended height

For some reason, PST supplies 55-R093 for the rear, instead.

55-R093 has the same exact specs (Collapsed/Extended length) as the R092 but the eyelets/bushings are different diameter (upper eye is 5/8" instead of 11/16"). This is why I had to drill out the upper bushing.

If any PST people are following this thread, I hope you can correct your listing.

-